Method for recovering indium and tin from ITO waste target materials on basis of distillation

A distillation method and target technology, which are applied in the field of comprehensive recovery of indium and tin, and can solve the problems of loss and low recovery rate of indium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

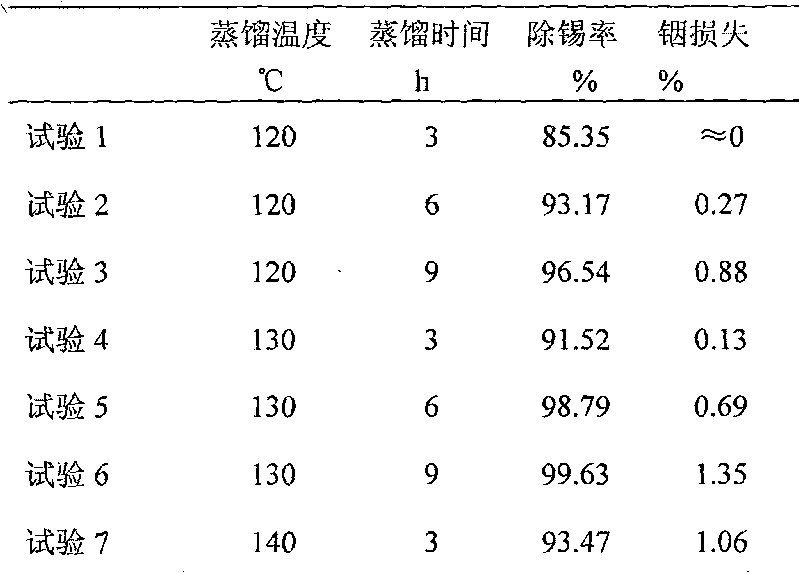

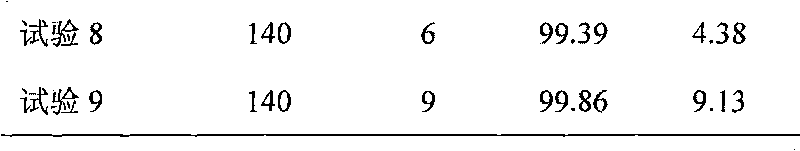

[0012] The technical solutions of the present invention will be further described below through specific examples.

[0013] 1. Principle

[0014] SnCl at atmospheric pressure 4 The boiling point is 113°C, InCl 3 Sublimation begins at about 148-440°C (different documents InCl 3 The sublimation temperature is inconsistent, in order to reduce the distillation loss of indium, 148 ° C is used as a reference). Using SnCl 4 has a lower boiling point and is compatible with InCl 3 There is a certain interval between the sublimation temperature, consider distilling it with InCl 3 Separation so as to achieve the purpose of indium tin separation.

[0015] The reaction of ITO powder and hydrochloric acid is:

[0016] In 2 o 3 +6HCl=2InCl 3 +3H 2 o

[0017] SnO 2 +4HCl=SnCl 4 +2H 2 o

[0018] First leaching the ITO powder with hydrochloric acid, taking the leaching clear liquid for direct distillation, and controlling the temperature so that the SnCl 4 Distillation and sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com