Welding process method of novel Q460 steel for transmission tower

A technology of welding process and transmission tower, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., and can solve the problem of no welding connection

Inactive Publication Date: 2010-05-05

HENAN NO 1 THERMAL POWER CONSTR

View PDF0 Cites 28 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Since the new Q460 steel was first used in the Olympic "Bird's Nest" project, its welding application in transmission towers is limited to the discussion stage, and has not been used in domestic transmission towers, such as the Pingluo (Pingdingshan-Luonan) line project, Although the "Q460 high-strength steel" iron tower was adopted first, all components are connected by bolts and no welded connections

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

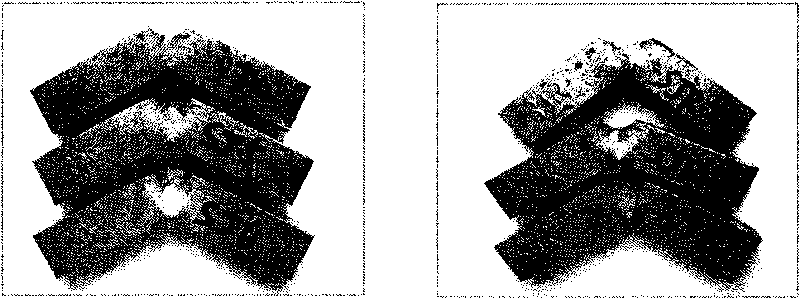

[0102] Embodiment 1: Test report on impact toughness of heat-affected zone of Q460 steel butt joint of the present invention:

[0103] Client: Henan First Thermal Power Construction Company

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Login to View More

Abstract

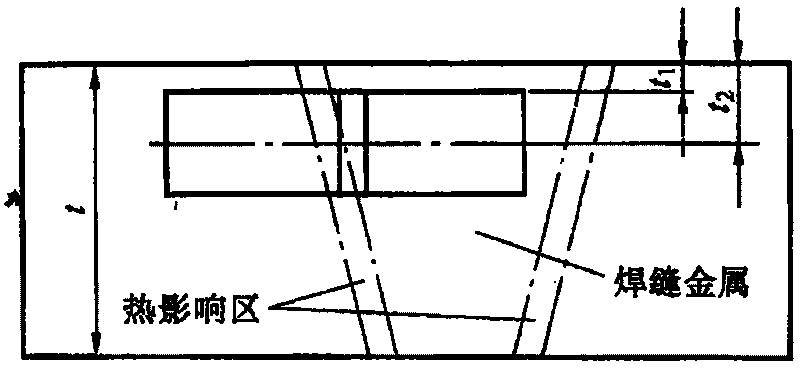

The invention discloses a welding process method of novel Q460 steel for transmission tower. The concrete process parameters are as follows: (1) selecting J607 welding rod or JM-60 solid welding wire for welding use; (2) selecting proper groove form according to the thickness of plate; (3) preheating to 50-100 DEG C when constructing outdoors or under an environment temperature of 0 DEG C, while not preheating when constructing indoors; (4) controlling heat input range during welding, at 12-21kJ / cm when the thickness of plate being less than or equal to 20mm, and at 15-45kJ / cm when the thickness of plate being more than 20mm; (5) adopting multi-layer multi-channel welding process with the temperature between channels not more than 150 DEG C; and (6) eliminating stress treatment and post-weld heat treatment. The inventive welding process method of novel Q460 steel can ensure successful application of Q460 high-strength steel in extra-high voltage transmission equipment, thus enhancing scientific level of the transmission field of China, and having great significance in construction of extra-high voltage grid of China.

Description

1. Technical field: [0001] The invention relates to a steel welding process method, in particular to a welding process method of a new type of Q460 steel used for power transmission iron towers, and belongs to the technical field of iron and steel material welding. 2. Background technology: [0002] At present, my country's transmission tower materials are mainly Q235 and Q345 hot-rolled equilateral angle steel. Some foreign developed countries have successfully applied high-strength steel to transmission towers. The application of high-strength steel in my country is obviously behind foreign countries. In Japan, steel pipe S55 high-strength steel (yield strength 415MPa) was used in the 1000KV transmission lines built as early as the 1990s. At present, the yield strength of high-tensile steel for iron towers reaches 520MPa, and the yield strength of welded structural steel reaches 460MPa. . The steel strength in the "Design Guidelines for U.S. Transmission Towers" has reach...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K9/23B23K9/095B23K9/235B23K33/00B23K35/12B23K9/16B23K103/04

Inventor 黄关政周志强郑凯乔学建金新宇孙建华于满红王学邱明林常建伟孙松涛张新伟何占利熊建坤李中六夏跃广黄杰陈东旭郭美华

Owner HENAN NO 1 THERMAL POWER CONSTR

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com