Low-cost preparation method for high-elongation ductile iron castings

A high-elongation, ductile iron technology, applied in the direction of improving process efficiency, can solve the problems of mechanical properties decline of ductile iron castings, quality of molten iron, increase of free carbon, etc., to reduce costs, reduce raw material costs, and improve economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

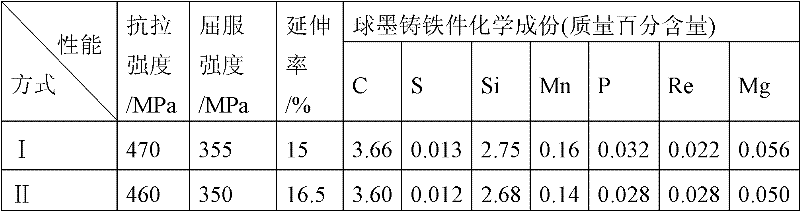

[0010] Specific embodiment 1: The method for preparing high elongation ductile iron castings at low cost in this embodiment is realized by the following steps: 1. Adding pig iron as the bottom material in the smelting furnace, and then adding recarburizer, remaining pig iron, Scrap steel, recycle material, manganese alloy and silicon alloy are then heated to 1520~1550℃ to melt the contents of the smelting furnace into molten iron, then calm and slag off, and then control the temperature of molten iron to be out of the furnace at 1490~1510℃. The mass ratio of the recycled material is 5:2, the mass ratio of the total mass of pig iron to the recycled material is 3:2, the mass of the recarburizer is 3% to 4% of the mass of the scrap steel, and the manganese content in the molten iron is controlled to the total mass of the molten iron. 0.2% to 0.4% of the molten iron, and the content of silicon in the molten iron is 2.5% to 2.9% of the total mass of the molten iron; 2. Add spheroidiz...

specific Embodiment approach 2

[0013] Specific embodiment two: This embodiment is different from the specific embodiment one in that it is heated to 1530-1540°C in step one. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: this embodiment is different from specific embodiment one in that it is heated to 1535°C in step one. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com