High-precision pentahedral machining machine tool

A technology for processing machine tools and pentahedrons, applied in the field of high-precision pentahedron processing machine tools, can solve problems such as increasing the machine tool head change stroke and occupied space, increasing the length of beam castings and guide rail strokes, and the easy deformation of the workbench. The effect of preventing table top deformation, low cost, and reduced head change stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

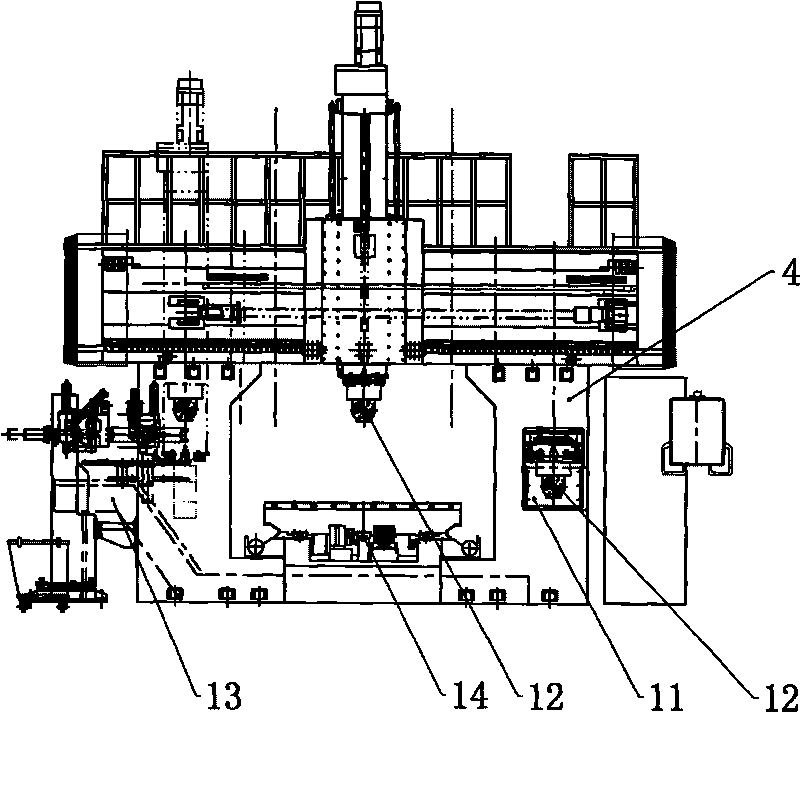

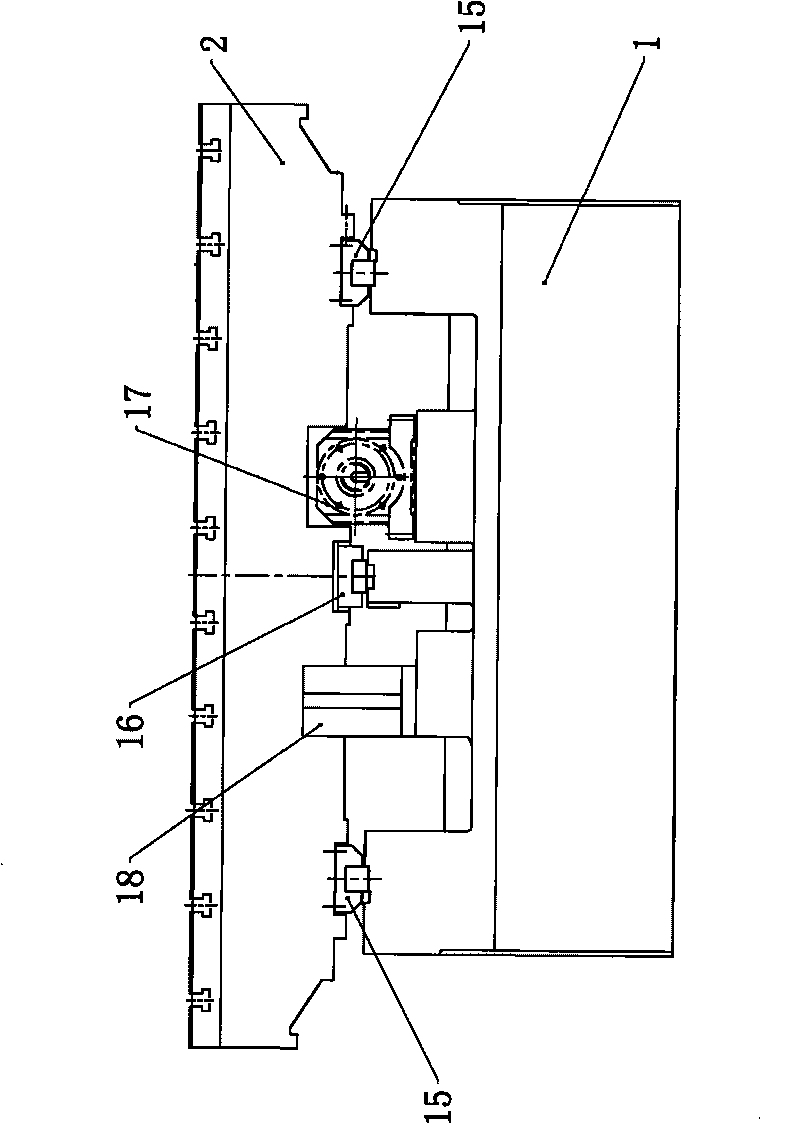

[0025] refer to Figure 1 to Figure 7 , this embodiment includes a machine bed 1, a workbench 2, a beam 3, a left column, a right column 4, an electrical control box 5, a console 6, a main transmission box 7, a ram 8, a carriage 9, a tool magazine 10, Automatic head magazine 11, right-angle milling head 12 and chip conveyor 13; guide rail 14 is arranged between machine bed 1 and worktable 2; automatic head magazine 11 is arranged on right column 4; guide rail 14 includes The linear rolling guide rails 15 on the left and right sides and a steel-inlaid rolling guide rail 16 arranged in the middle of the machine bed; a workbench limit device 18 and an adjusting screw 17 are arranged between the machine bed 1 and the workbench 2; The rolling guide rail includes an inlaid steel block 19, a rolling block 20 and a fixed block 21 of the rolling block. The inlaid steel block is fixed on the seat body 23 of the machine bed, the rolling block is fixed on the fixed block of the rolling bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com