Device for cleaning flat panel

A cleaning device and flat panel technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems such as harmfulness to operators, environmental pollution, and easy discoloration of etched surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

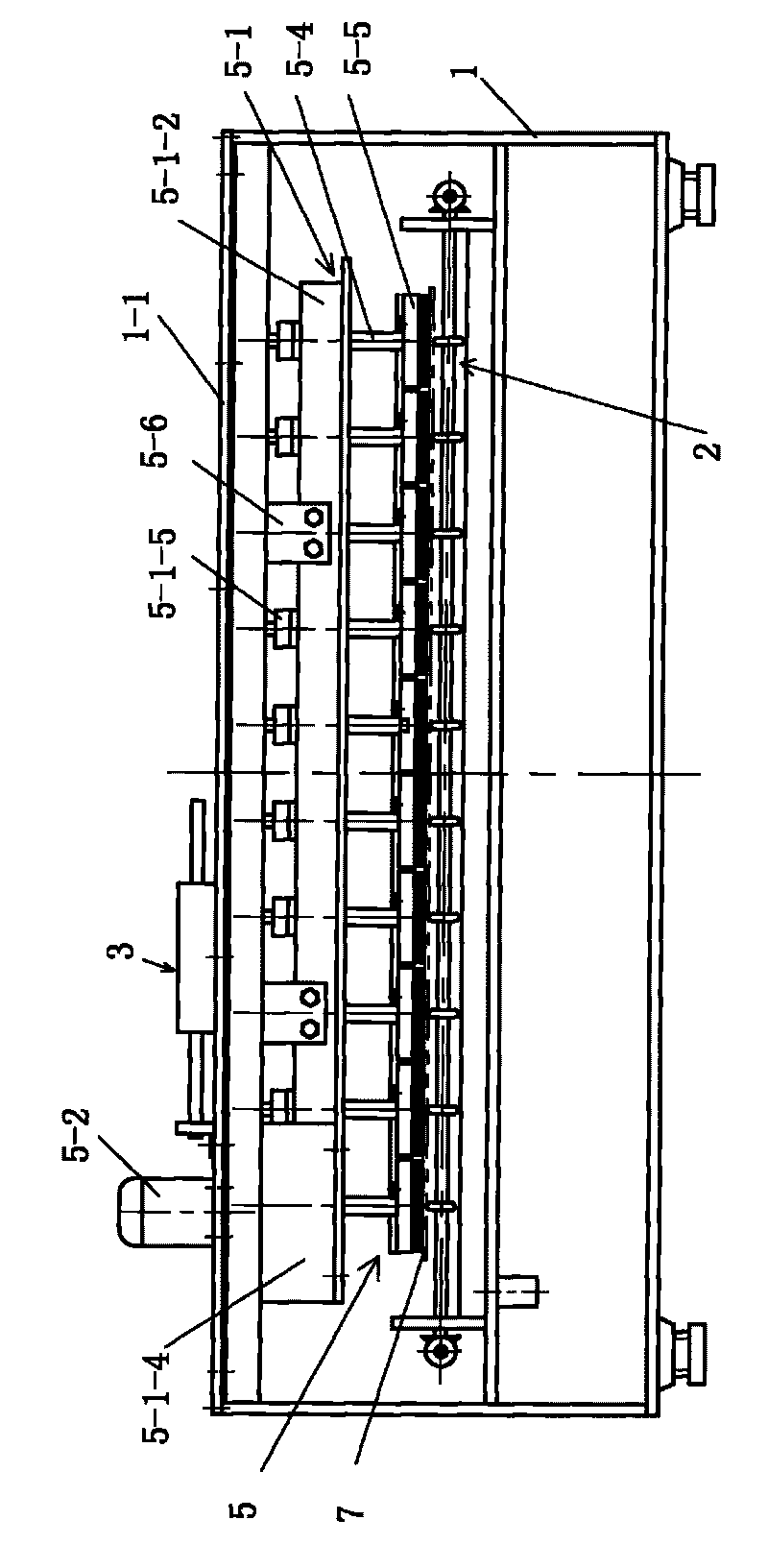

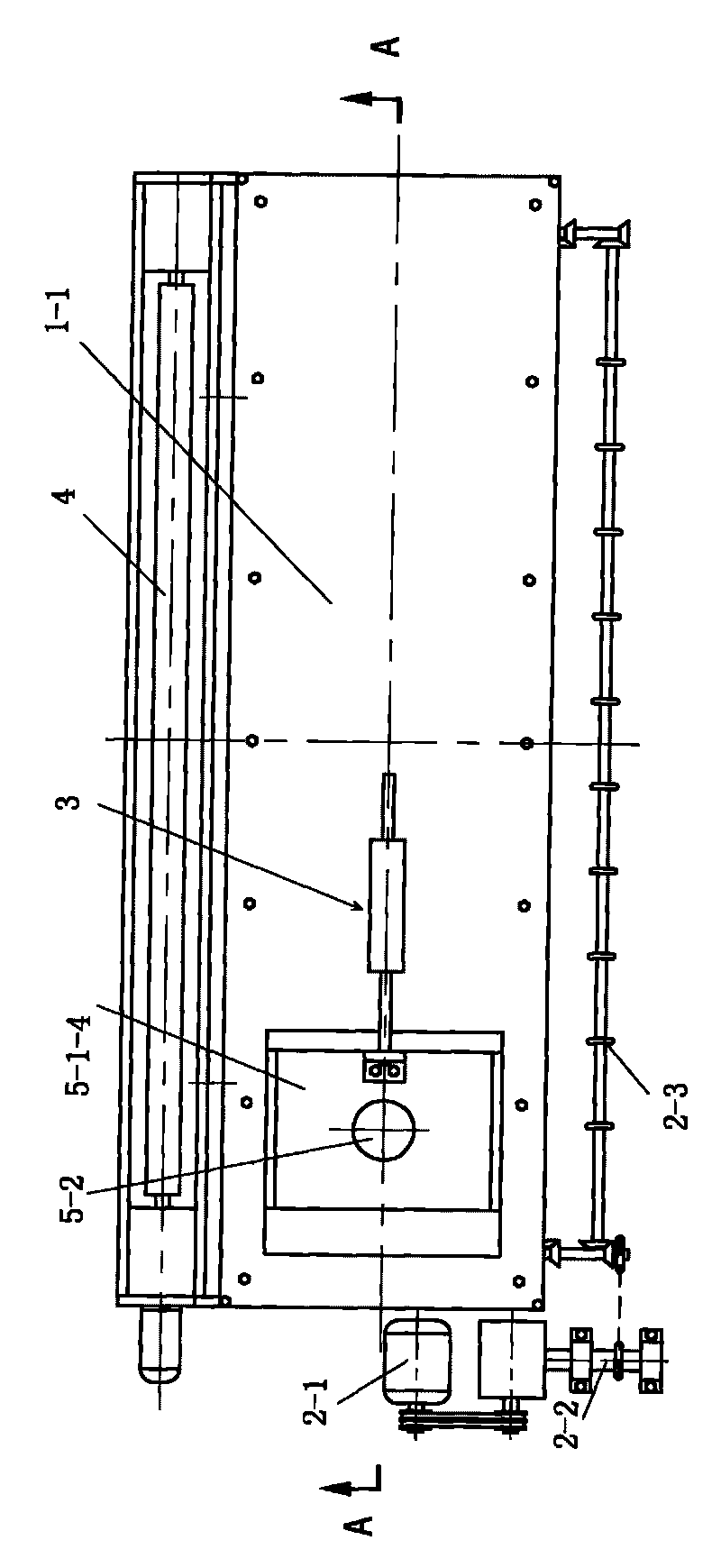

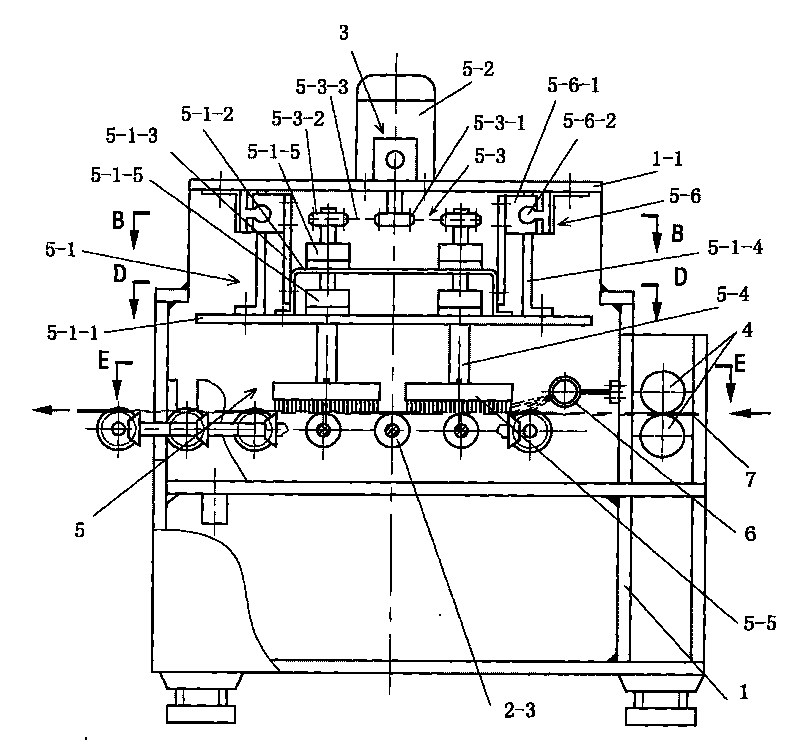

[0024] Such as figure 1 , 2 , 3, the flat plate cleaning device of the present invention comprises frame 1, conveying mechanism 2, scrubber 5 and reciprocating drive mechanism 3, conveying mechanism 2 is contained on the frame 1, and scrubber 5 is located at the top of conveying mechanism 2 , the scrubber 5 comprises a moving frame 5-1, a motor 5-2, a transmission mechanism 5-3 and several brushes 5-5 with a rotating shaft 5-4, wherein the motor 5-2 is fixed on the moving frame 5-1, and the motor 5-2 is driven and connected to the rotating shaft 5-4 through the transmission mechanism 5-3, and the rotating shaft 5-4 is rotatably supported on the moving frame 5-1, and the moving frame 5-1 is slidingly connected with the frame 1 through the sliding part 5-6, and the reciprocating drive Mechanism 3 is connected with frame 1 and mobile frame 5-1 respectively.

[0025] Such as image 3 , 6 , 8, in order to remove most of the chemical liquid on the flat plate before washing, at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com