Powdered-coating processing device in preparation process of helical fluorescent lamp tube

A fluorescent tube and preparation process technology, applied in the field of spiral fluorescent tube preparation devices, can solve the problems of phosphor waste, phosphor deposition, increased labor costs, etc., and achieve the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

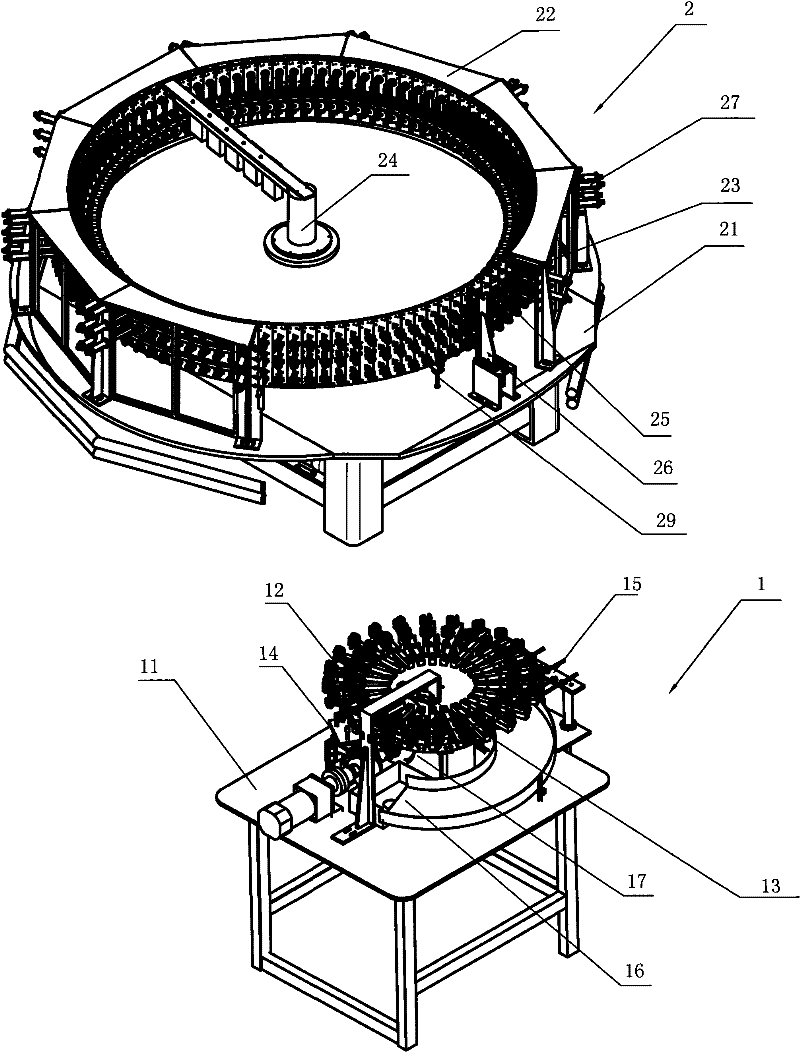

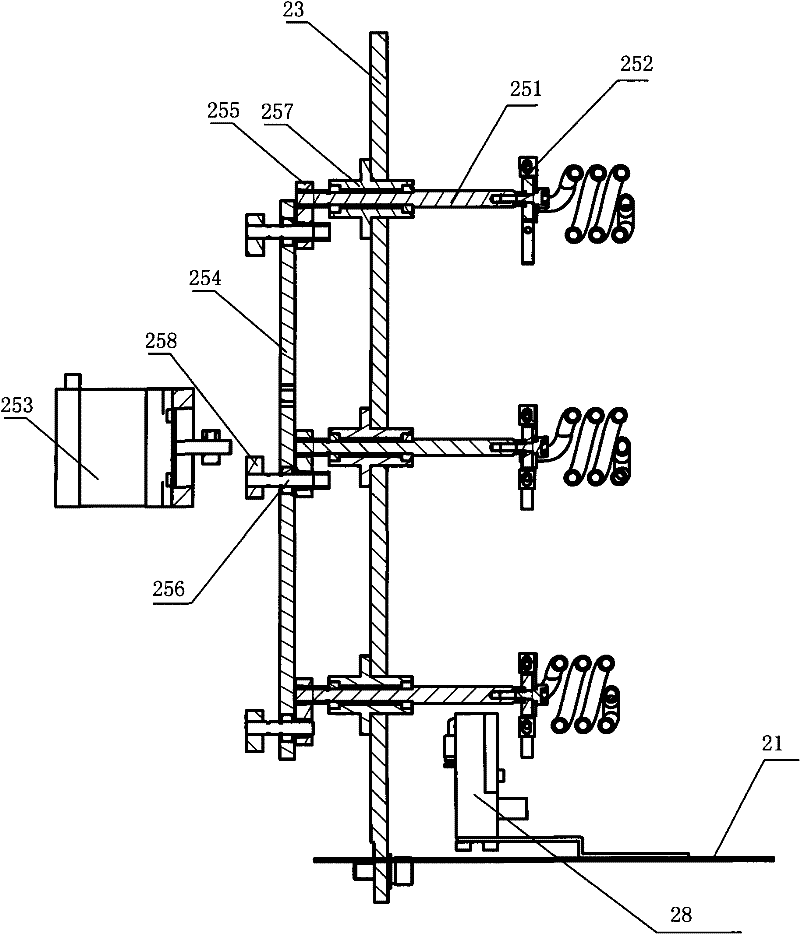

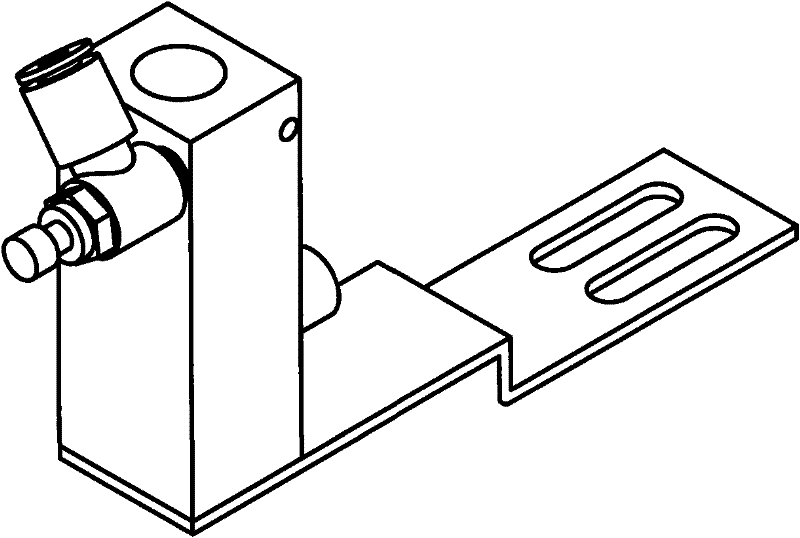

[0019] A powder coating processing equipment in the preparation process of a spiral fluorescent tube includes a powder coating device 1 and a drying device 2. The drying device 2 includes a first working table 21 on which an oven 22 and a cylindrical frame are arranged 23 and the first divider 24 that drives the frame 23 to rotate intermittently around the axis. A part of the frame 23 is surrounded by an oven 22. The outer surface of the frame 23 is provided with multiple sets of tube holding devices 25 along the circumference. It includes three pipe holders 251 extending in an axial direction and extending horizontally and radially. The head of the pipe holder 251 is provided with a pipe holder 252. Each group of pipe holder devices 25 is provided with a drive pipe holder 251 around the axis. A rotating drive mechanism. The drive mechanism includes a step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com