High voltage outgoing line device of extra-high voltage transformer

A technology of high-voltage outgoing wires and high-voltage outgoing wires, applied in the direction of transformer/inductor coil/winding/connection, preventing/reducing unnecessary electric/magnetic influence, etc., can solve the problem that the number and size of oil gaps cannot meet 1000kV and The above problems such as the insulation requirements of UHV transformers, partial discharge of high-voltage outlet devices, and difficulty in cleaning welding slag have achieved the effects of weight reduction, reduced electric field strength, and reasonable field strength distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

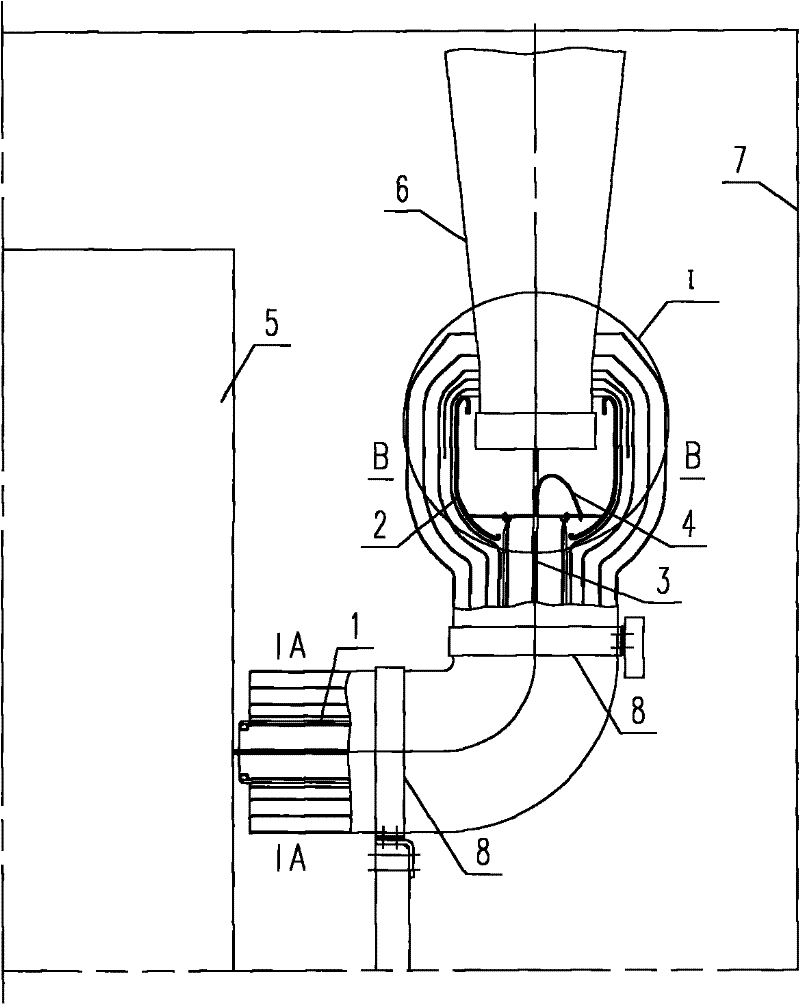

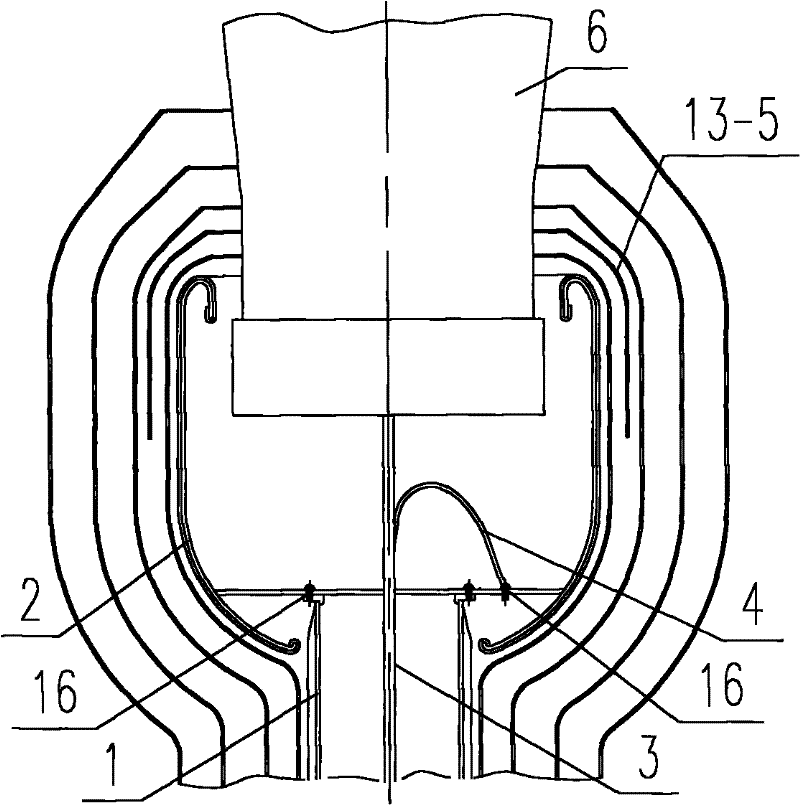

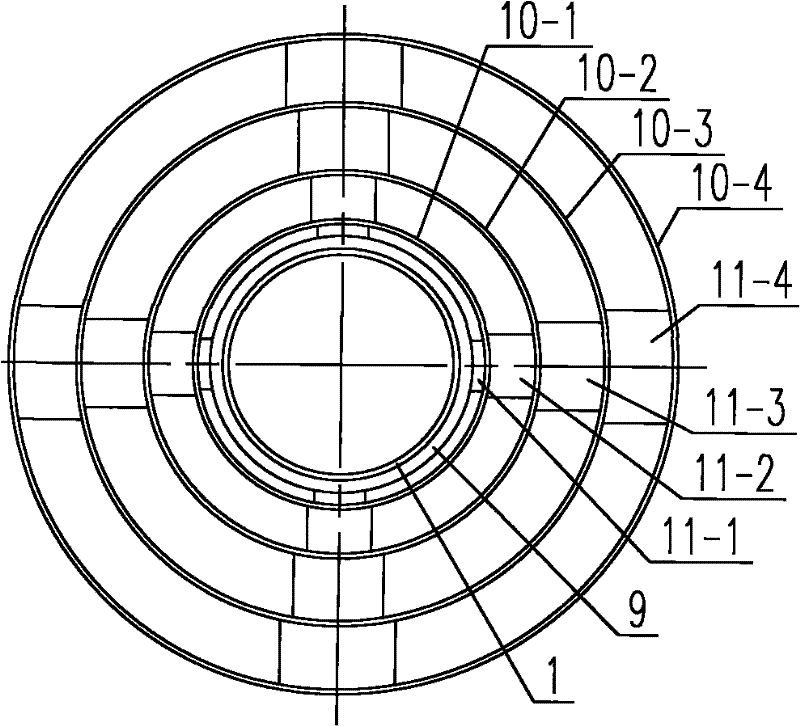

[0020] Such as figure 1 figure 2 As shown, the high-voltage outlet device of the present invention consists of a pressure equalizing tube 1 and a pressure equalizing ball 2 through the

[0021] The metal bolts 16 with the lock function are reliably connected to form an integral body as electrodes. The material of the pressure equalizing tube 1 and the pressure equalizing ball 2 can be made of copper or aluminum. In the pressure equalizing tube 1, the potential connection line 4 of the high voltage lead-out line is reliably connected to the pressure equalizing ball 2 in the pressure equalizing ball 2, so that the high-voltage lead-out line 3, the pressure equalizing ball 2 and the part 6 in the high-voltage bushing oil become equipotential . The high-voltage lead-out line 3 is led out through the oil middle part 6 of the high-volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com