New method for extracting and separating high-purity huperzine A from thousand-layer column

A technology of huperzine A and Melaleuca tower, which is applied in the field of extraction and separation of high-purity huperzine A, can solve the problems of not meeting market demand, small production scale, and low product purity, and achieve saving of reagents, short process cycle, The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Preparation of the extract: ① Add 3-25 times the amount of 0.2-2% sulfuric acid to the pulverized Melaleuca tower, and soak it at room temperature for 0-24 hours; The extract is ready for use;

[0028] Macroporous resin pre-separation: ① adjust the pH of the extract to 8-10, and put it on a macroporous adsorption resin column; ② use 0-15% ethanol for the first time to elute, and discard the eluent; ③ use 15% for the second time -Elute with 70% ethanol, collect the eluent, recycle the ethanol, and obtain the extract extract;

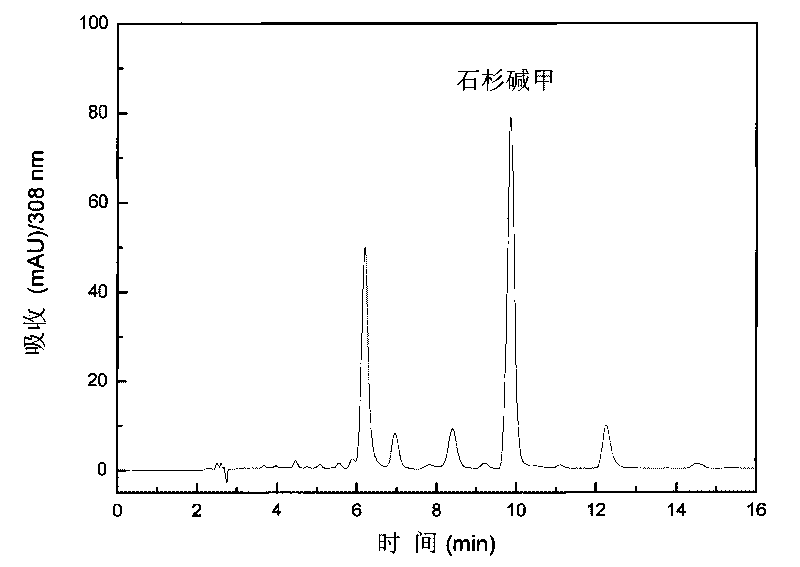

[0029] Purification by high-speed countercurrent chromatography: using petroleum ether-n-butanol-phosphate buffer as a solvent system, the crude extract of huperzine A obtained above is purified by high-speed countercurrent chromatography to obtain high-purity huperzine A. The purity is above 98%.

Embodiment 1

[0031] Take 100g of crushed melaleuca medicinal material, add 1.5L of 1% sulfuric acid, soak at room temperature for 24 hours, percolate until no huperzine A can be detected in the effluent, and adjust the pH of the extract to 8 with ammonia water.

[0032] Put the above pH-adjusted extract on a macroporous adsorption resin column, elute with 5% ethanol until the effluent is colorless, and discard the eluent. Then elute with 30% ethanol, detect that there is no huperzine A in the eluate, collect the eluate, and distill under reduced pressure to recover the solvent to obtain the extract of huperzine A.

[0033] Using petroleum ether-n-butanol-phosphate buffer as a high-speed countercurrent chromatography two-phase solvent system to separate and purify the extract of huperzine A, the stationary phase is petroleum ether-n-butanol (1.5:3.5, V / V), and the mobile The phase is a phosphate buffer containing both sodium dihydrogen phosphate and disodium hydrogen phosphate at 1%.

Embodiment 2

[0035] Take 100g of crushed melaleuca medicinal materials, add 1.5L of 1% sulfuric acid, soak at room temperature for 24 hours, and ultrasonically sonicate for 30 minutes to separate the medicinal liquid. 1L of 1% sulfuric acid was added to the medicinal residues, and the medicinal liquid was separated by ultrasonic treatment for 20 minutes. Combine the medicinal solutions, filter to remove impurities in the extract, and adjust the pH of the extract to 8.

[0036] Put the above pH-adjusted extract on a macroporous adsorption resin column, elute with 5% ethanol until the effluent is colorless, and discard the eluent. Then elute with 30% ethanol until there is no huperzine A in the effluent, collect the eluate, and distill under reduced pressure to recover the solvent to obtain the extract of huperzine A.

[0037] Using petroleum ether-n-butanol-phosphate buffer as a high-speed countercurrent chromatography two-phase solvent system to separate and purify the extract of huperzin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com