Heavy metal polluted sludge treatment method

A treatment method and heavy metal technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve heavy metal secondary pollution, low direct dehydration efficiency of geotextile bag, mechanical dehydration Problems such as high equipment investment and operating costs, low equipment investment and operating costs, avoiding health hazards for construction personnel, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

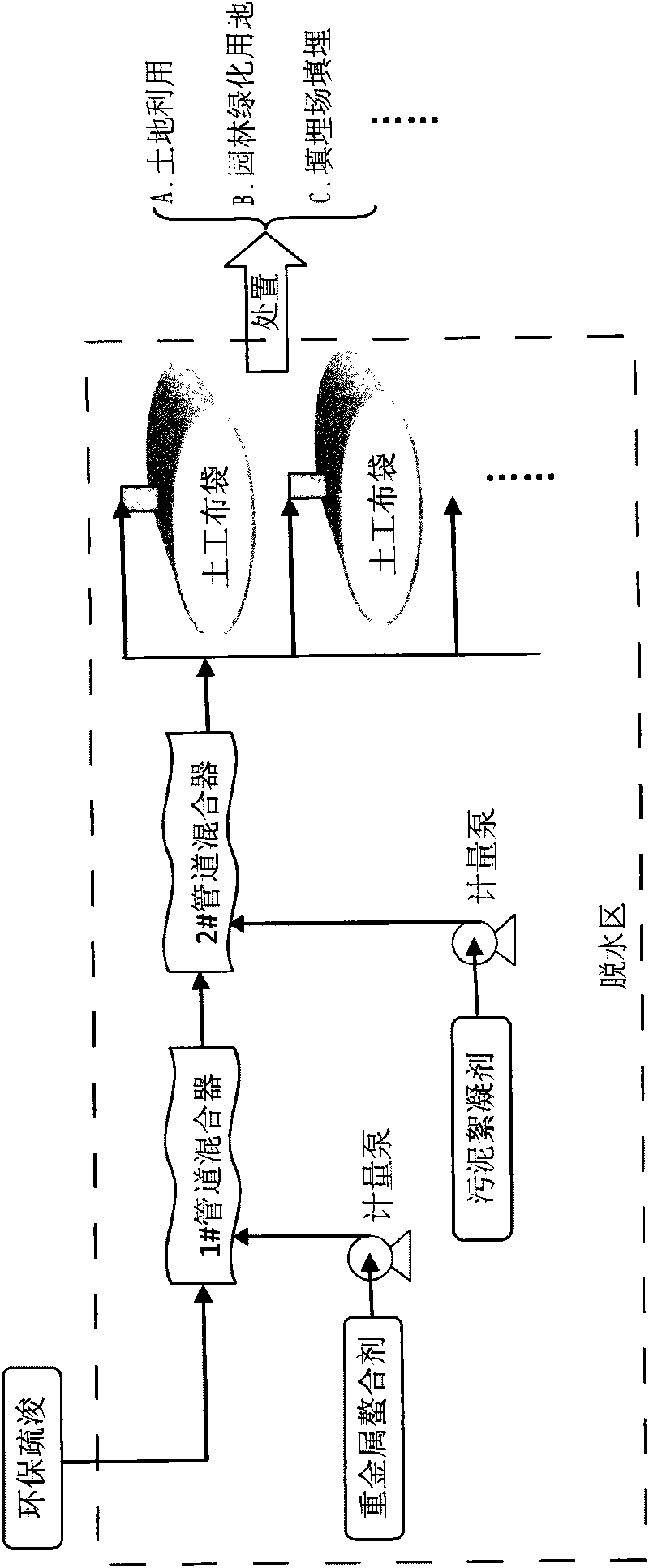

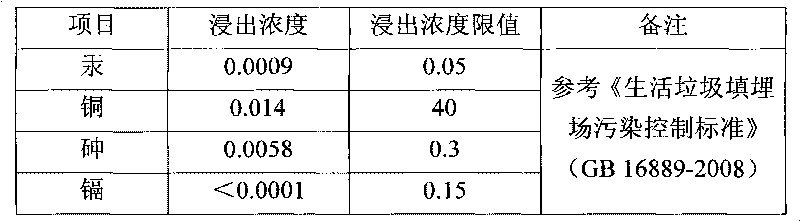

[0010] Embodiment 1: Adopt Dutch IHC Beaver 1200 type environmental protection dredging ship to carry out environmental protection dredging to the sludge polluted by heavy metals such as mercury, copper, cadmium in the Hangu sewage reservoir (contaminated sludge heavy metal content is as shown in Table 1), and the dredging flow rate is 400m 3 / h, the average moisture content of dredged silt is 91%. Use a metering pump to pump ES heavy metal chelating agent (Tianjin Yiming) into the first serpentine pipeline mixer, and the dosing flow rate is 200kg / h (equivalent dosage is about 5‰, calculated as dry sludge , weight ratio), the stable reaction time of the chelating agent is at least 1min. Use a metering pump to pump a cationic polyacrylamide flocculant solution (Jiangsu Nantian CSG-A20) with a concentration of 5‰ (weight ratio) into the second serpentine pipeline mixer, and add a flow rate of 40kg solid powder flocculant / h (the equivalent dosage is about 1.1‰, based on dry slu...

Embodiment 2

[0015]Embodiment 2: The implementation method is the same as that of Embodiment 1, and the content of heavy metals in the polluted sludge is changed, as shown in Table 3. Change the dosage flow of ES heavy metal chelating agent to 100kg / h (equivalent dosage is about 2.5‰, based on dry sludge, weight ratio). After the geotextile bag was filled and dehydrated and consolidated for 10 days, the average moisture content of the dewatered sludge in the bag was 54%. Refer to "Sludge Disposal of Urban Sewage Treatment Plants for Land Improvement of Mud Quality" (CJ / T 291), that is, the treated sludge contaminated with heavy metals such as mercury, copper, and cadmium can be used for land use.

[0016] Table 3 Heavy metal content in polluted sludge Unit: mg / kg

[0017] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com