Method and device for drying large-scale power transformer

A technology for power transformers and drying methods, applied in the field of transformers, can solve the problems of affecting deep water evaporation, short vacuuming time, and long production cycle, and achieve the effects of shortening the drying time, shortening the drying time, and accelerating the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

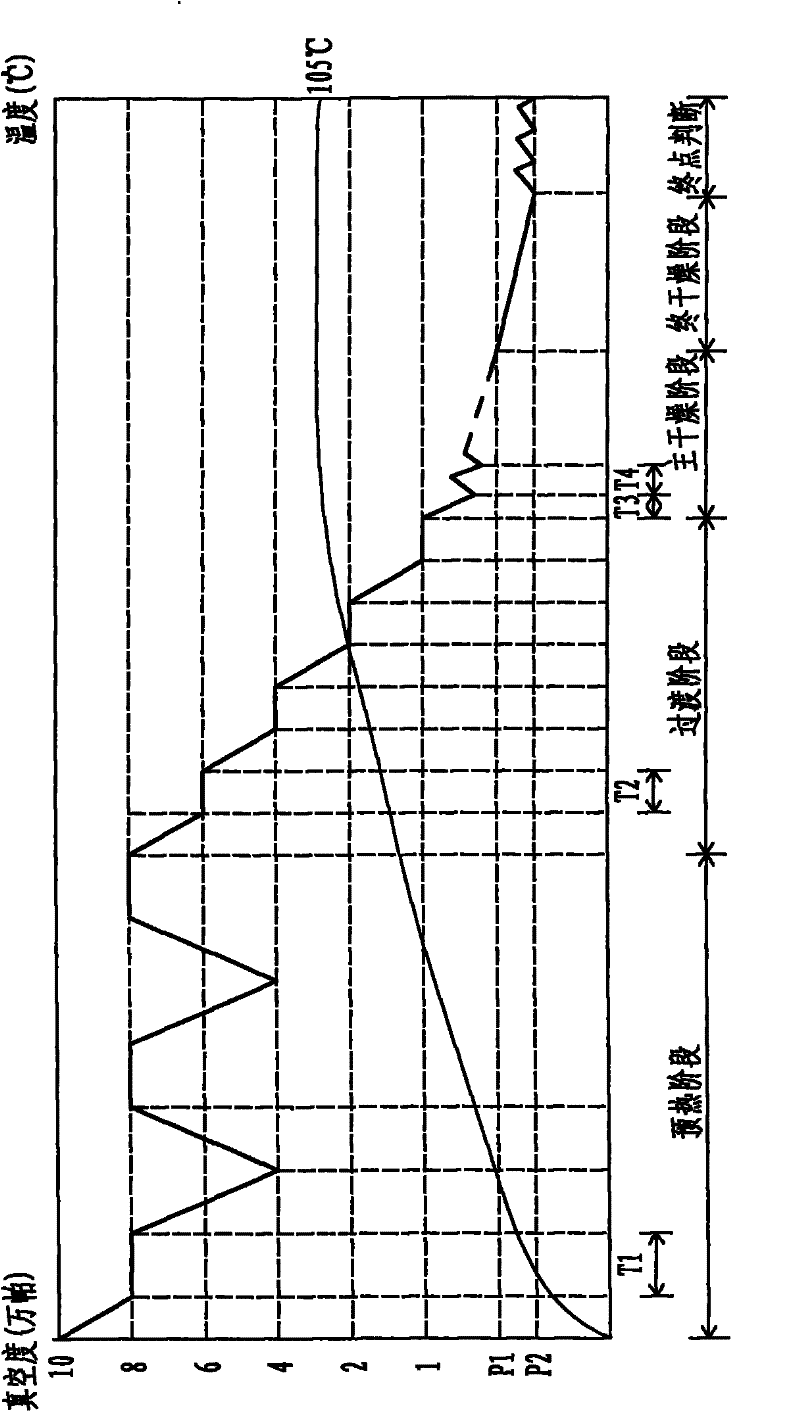

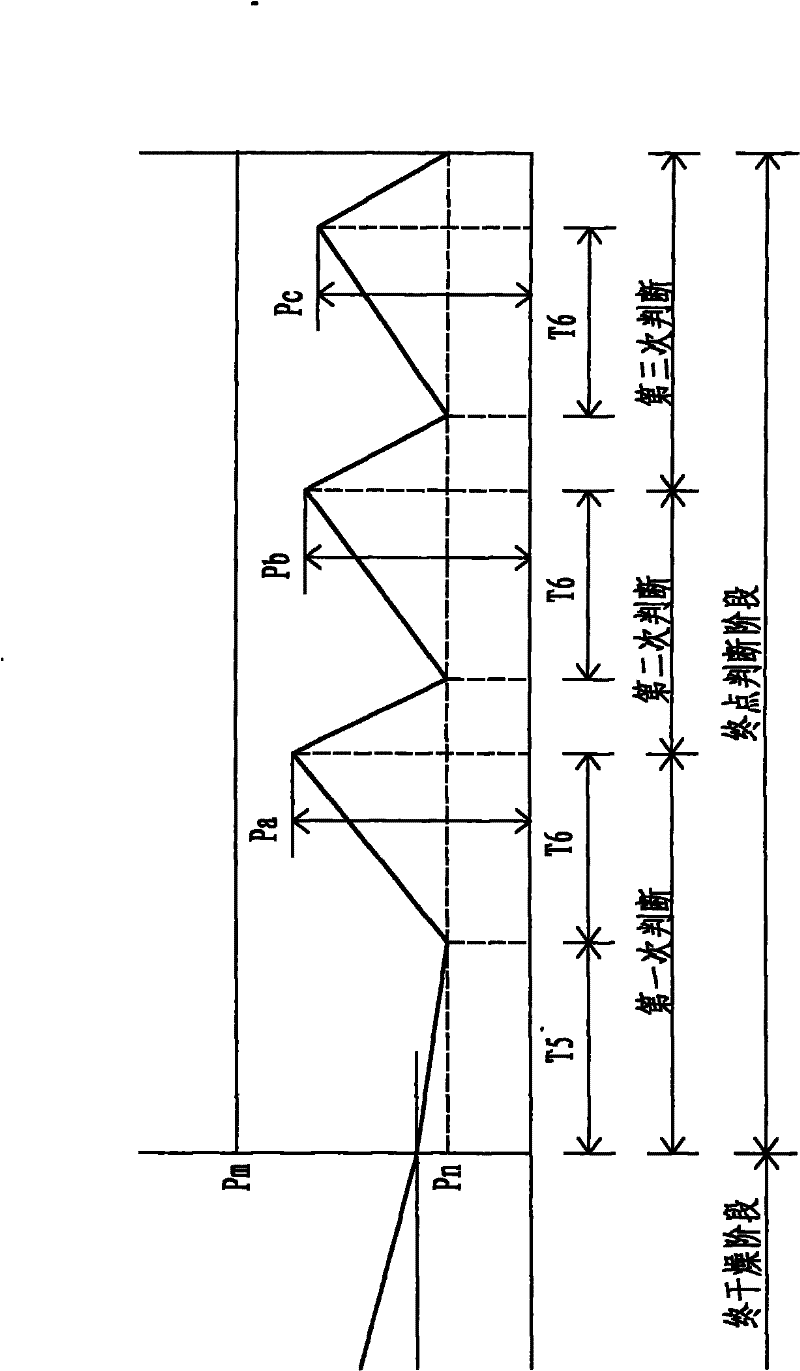

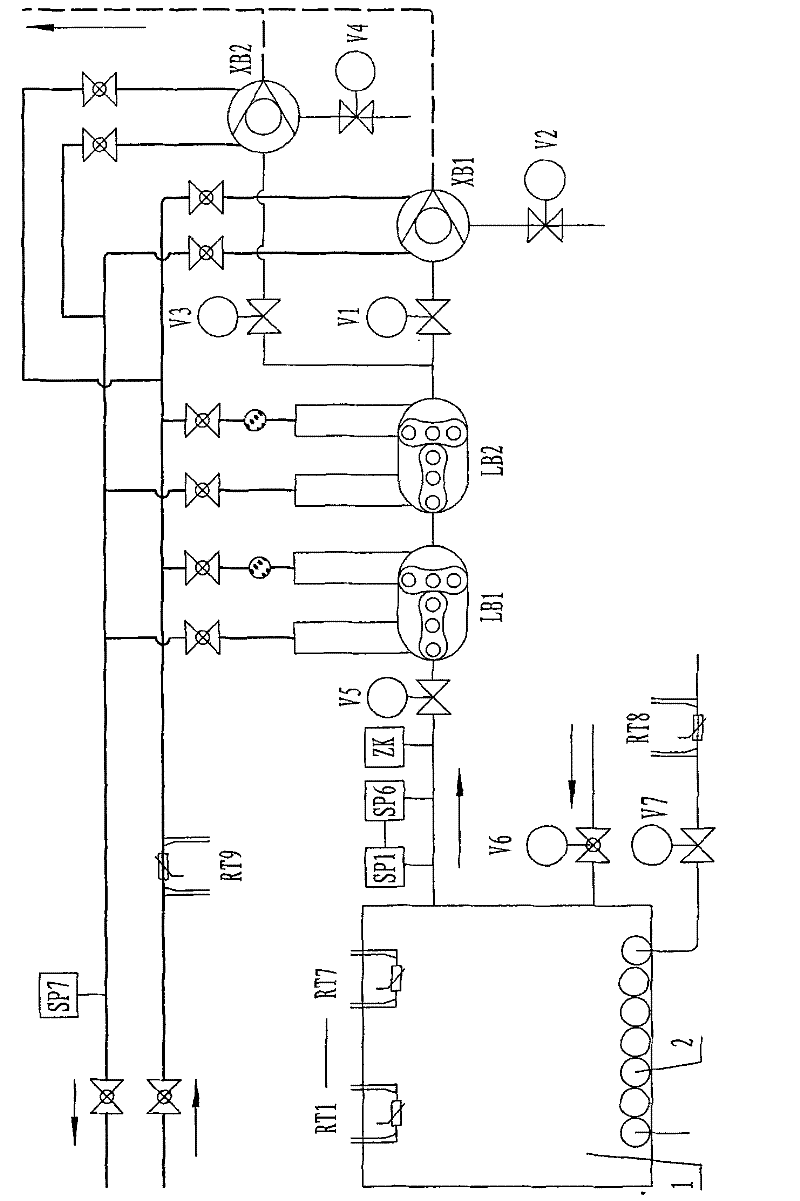

[0028] see figure 1 , The whole technological process of the present invention is divided into five stages: respectively preheating stage, transitional stage, main drying stage, final drying stage, end point judgment stage. In the preheating stage, the vacuum degree in the tank changes between 80,000 Pa and 40,000 Pa, and the temperature of the iron core rises to 72°C. This cyclical process makes the temperature distribution in the tank even, and can continuously remove the heat in the deep insulation material. The water evaporates; in the transition stage, it generally has to go through four steps of 80,000 Pa, 40,000 Pa, 20,000 Pa, and 10,000 Pa, and finally makes the vacuum in the tank reach 10,000 Pa; in the main drying stage, vacuum for a period of time, close the main Valve for a period of time, and so on, until the vacuum degree reaches the value specified in the process (usually 500 Pa); in the final drying stage, continue to vacuum until the vacuum degree finally reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com