Valve combination for regulating the flow rate or differential pressure

A valve group and differential pressure technology, used in flow control, auxiliary non-electrical flow control, control/regulation systems, etc. The effect of simplified installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

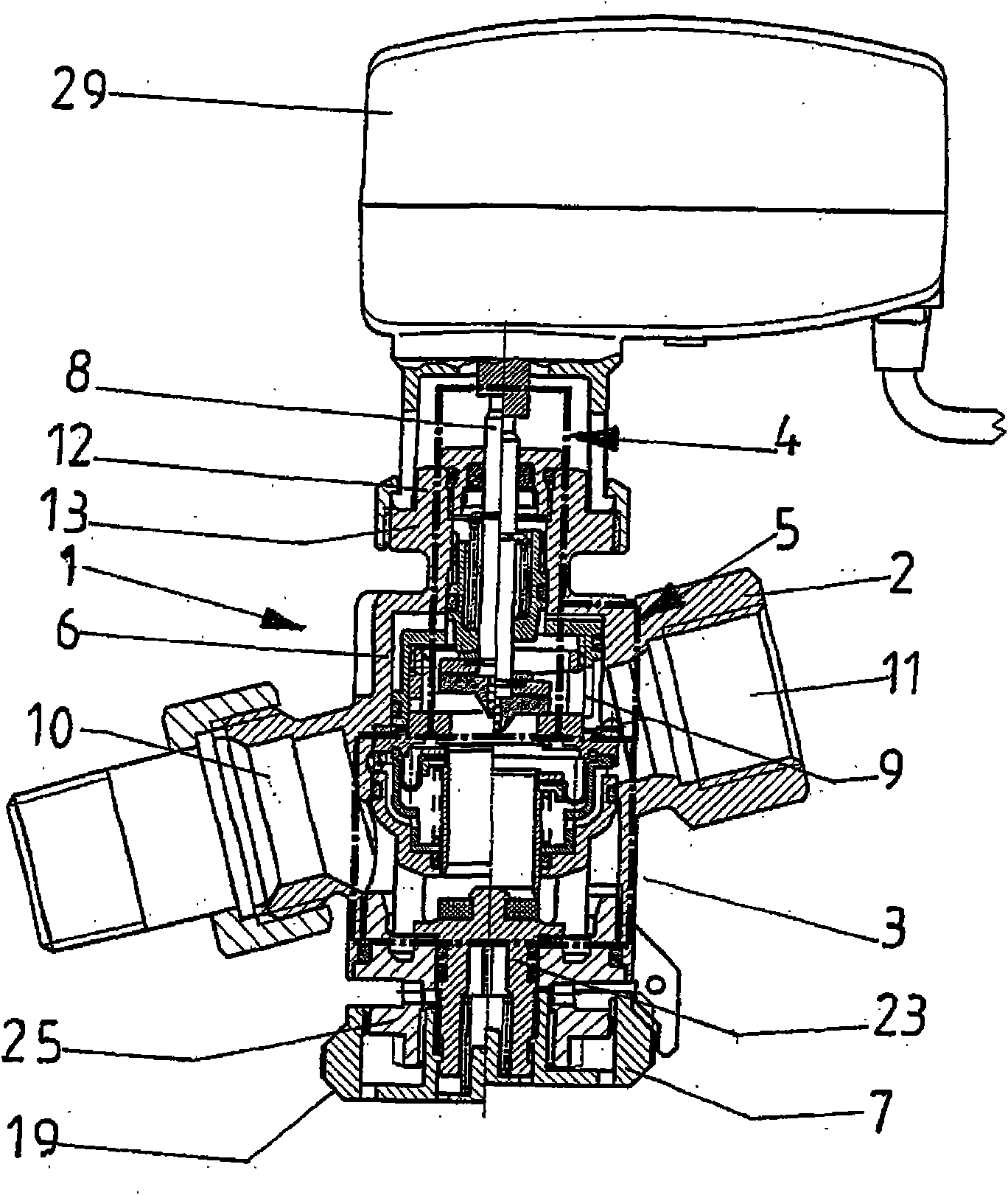

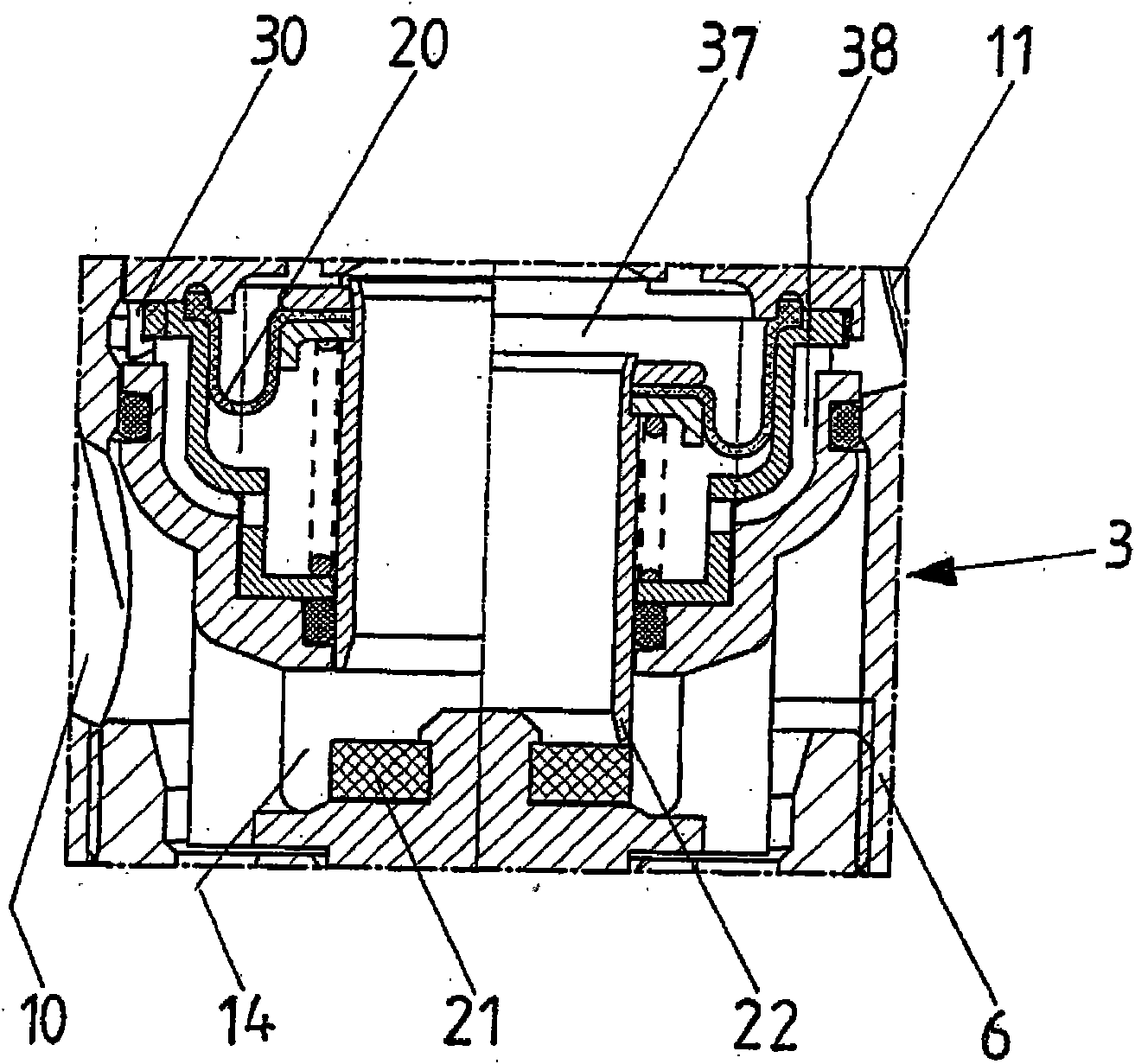

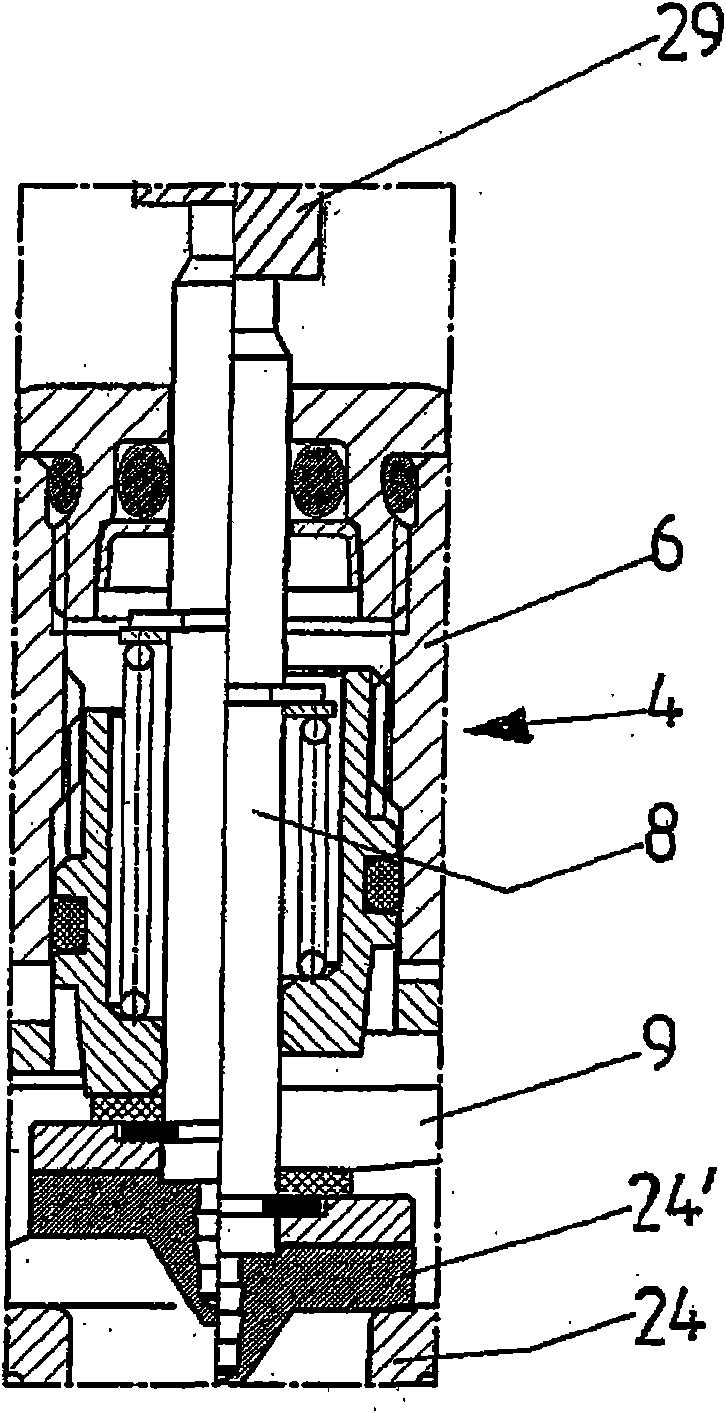

[0057] The figures show a valve block 1 for regulating a flow or a differential pressure in a fluid-carrying heating or cooling installation. It consists of a housing 2 with an inlet connection 10 , an outlet connection 11 and a connecting pipe 6 arranged between them. Arranged axially in the connecting pipe 6 is an adjustment device 3 which is equipped with a movable partition 20 for the rated load. The diaphragm 20 controls the differential pressure by means of a closure element 22 acting on the first support 21 to change the adjustment cross-section 14 , wherein the adjustment device 3 can be adjusted by means of a first flow adjustment also arranged axially in the connecting pipe 6 . The device 4 keeps the pressure difference constant at a predetermined value by means of a presettable second flow regulating device 5 arranged axially or coaxially with the first flow regulating device 4, wherein the first flow regulating device 4 It is adjustable via the actuating element 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com