Gripper, in particular a bernoulli gripper

A technology of grippers and suction cups, which is applied in the field of grippers, can solve problems such as wafer damage, and achieve the effect of reducing the risk of damage and reducing waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

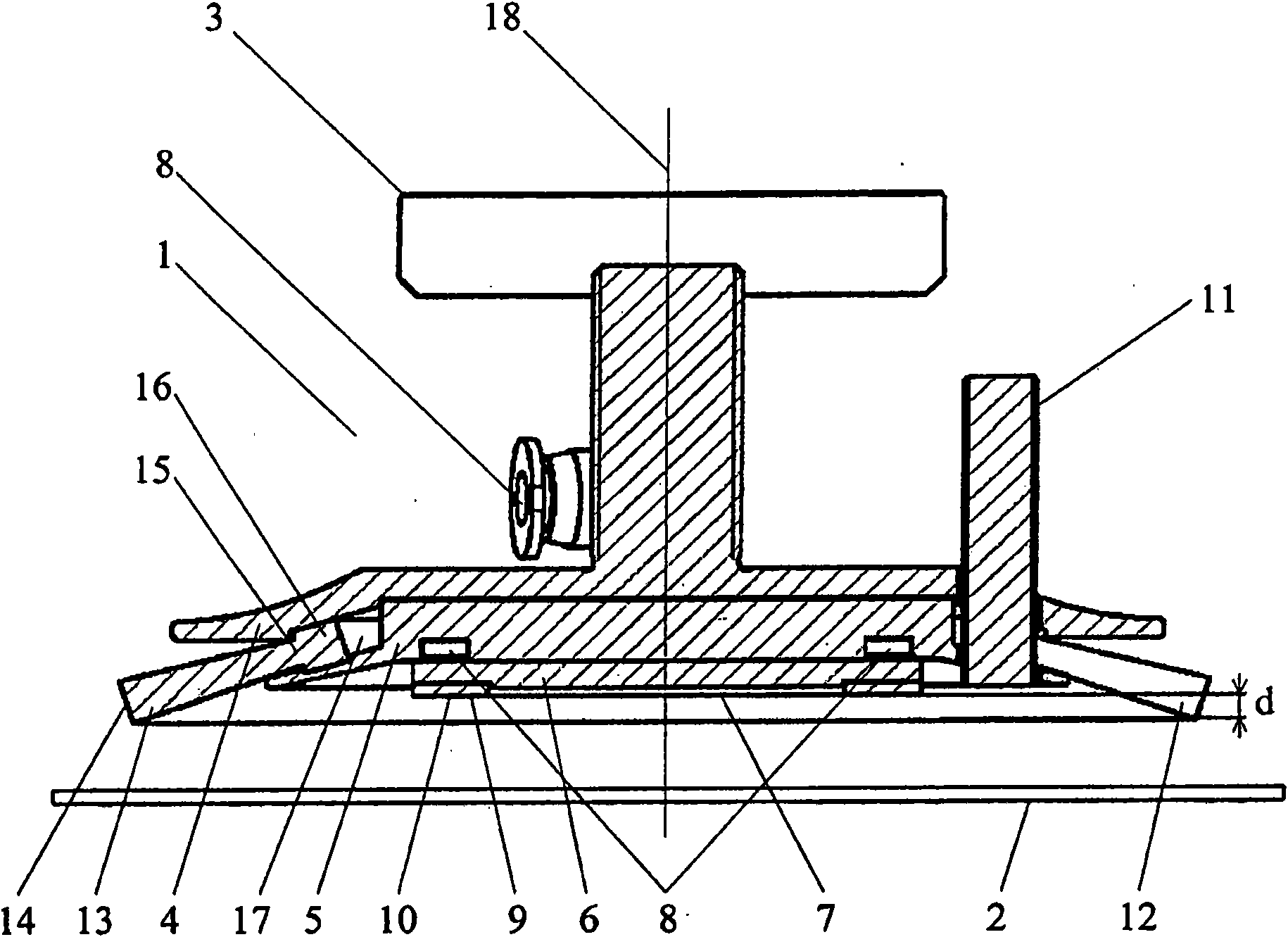

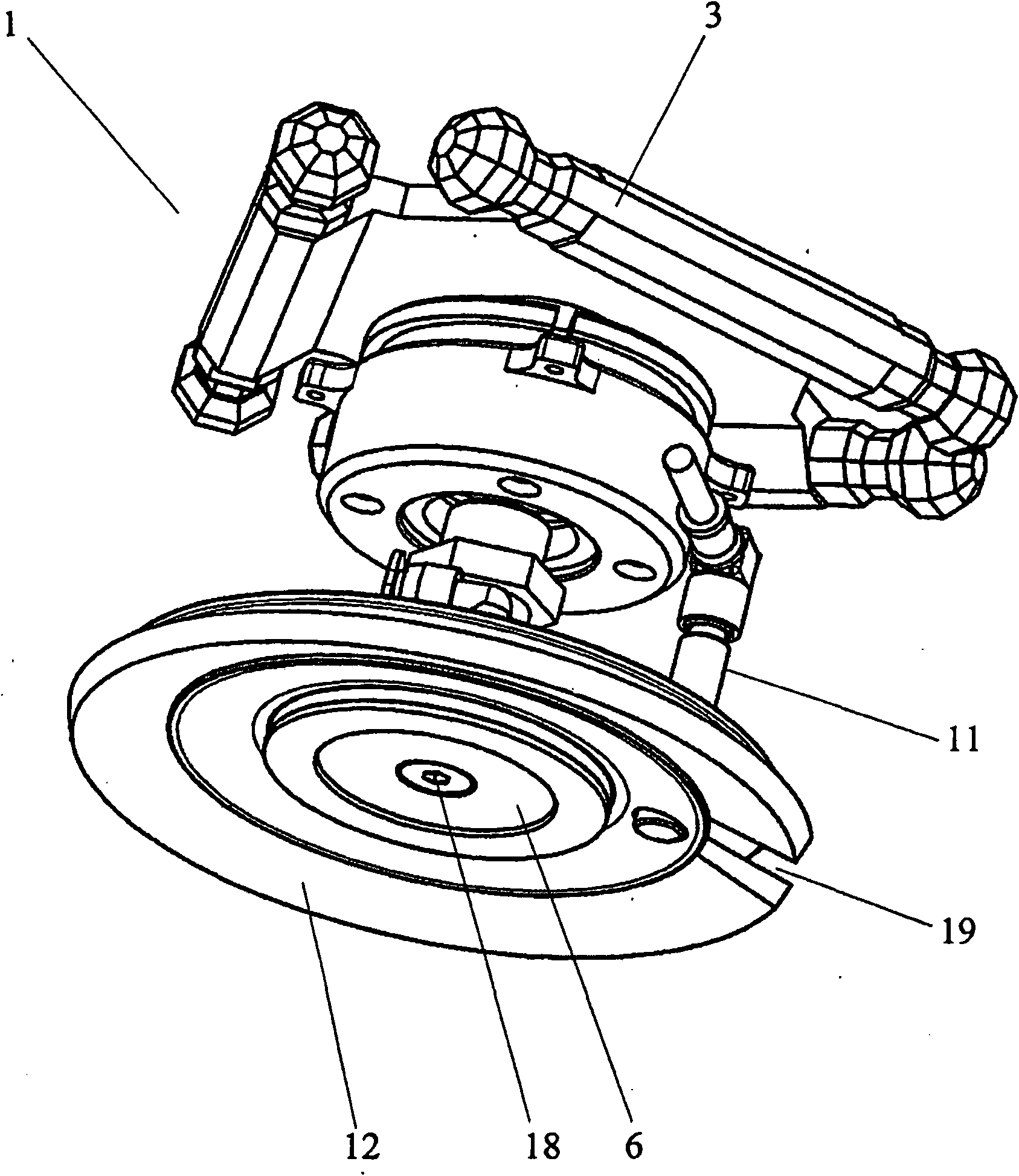

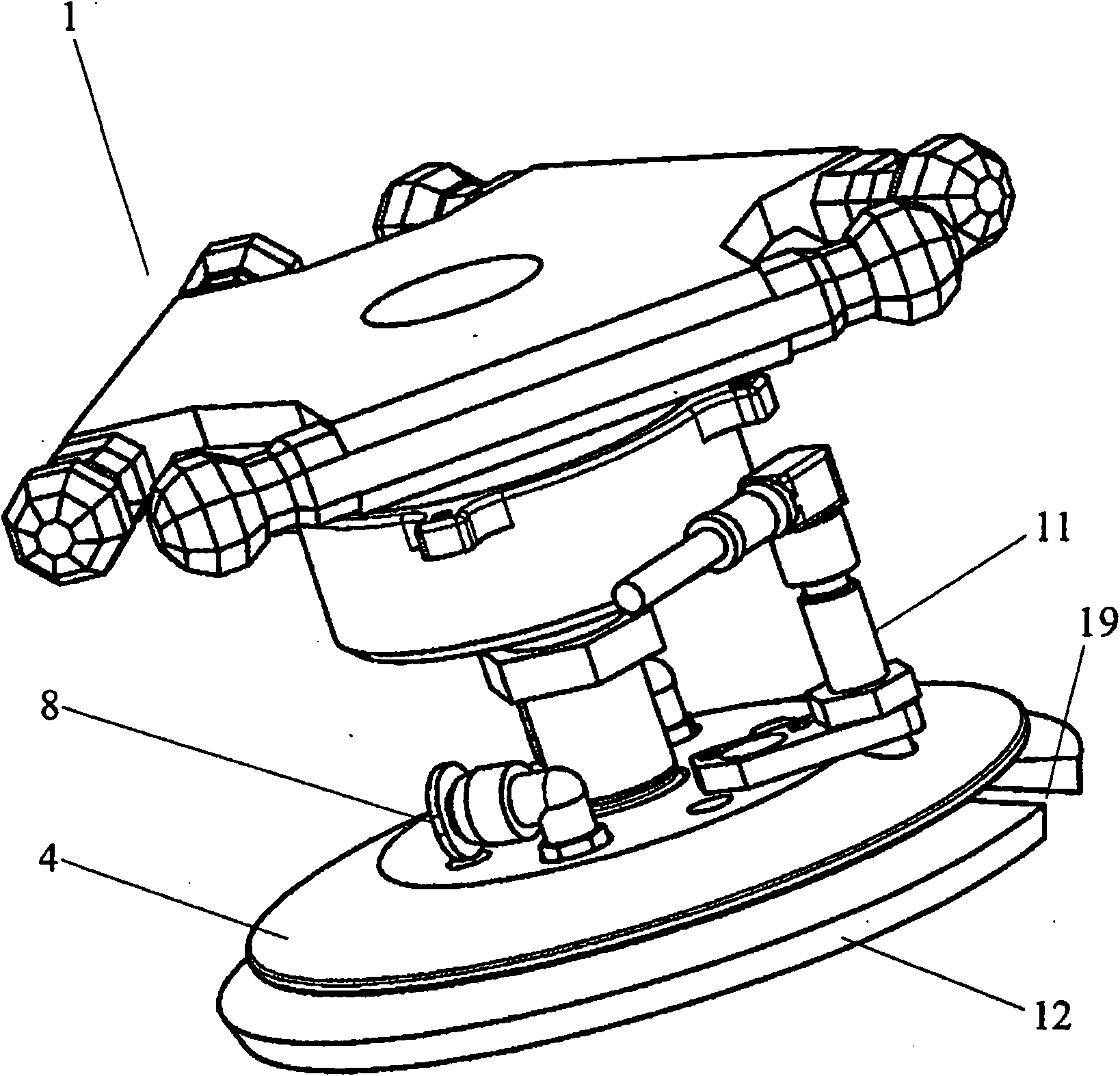

[0015] as by Figures 1 to 3 It can be seen that the Bernoulli chuck 1 for non-contact gripping of planar components such as silicon-based wafers 2 basically comprises a clamping ring 4 connected to at least one controllable robot arm 3; 6, which is connected to the clamping ring 4 via a horn-shaped component 5 and has a gripping surface 7, in which a rubberized bearing surface 9 of a support ring 10 is built; 6 of the flow system 8, which communicates with the gripping surface 7 of the gripper 1; a cushioning device 12 in the form of a brush with elastic bristles 19 adapted around the gripper 1 and a capacitive sensor for A wafer 2 held by the gripper 1 is identified.

[0016] When an overpressure is applied to the Bernoulli chuck 1 , a negative pressure is generated on the gripping surface 7 of the stopper 6 via the flow system 8 in order to grip the wafer 2 to be gripped due to the resulting pressure difference. Such as figure 1 It is best to explain that due to the arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com