Alignment mark, making method and detection device thereof

A technique for aligning marks and manufacturing methods, which is applied in photolithographic process exposure devices, pattern surface photographic process, semiconductor/solid-state device manufacturing, etc., which can solve the problems of insufficient use of cutting lines and reduction of the use area of front silicon wafers, etc. , to achieve accurate detection, reduce the front area of the silicon wafer, and increase the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

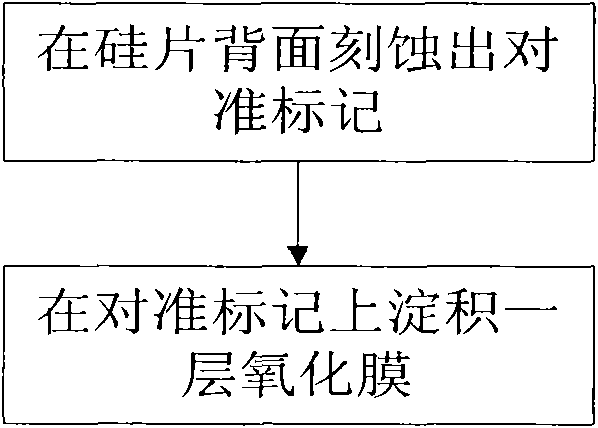

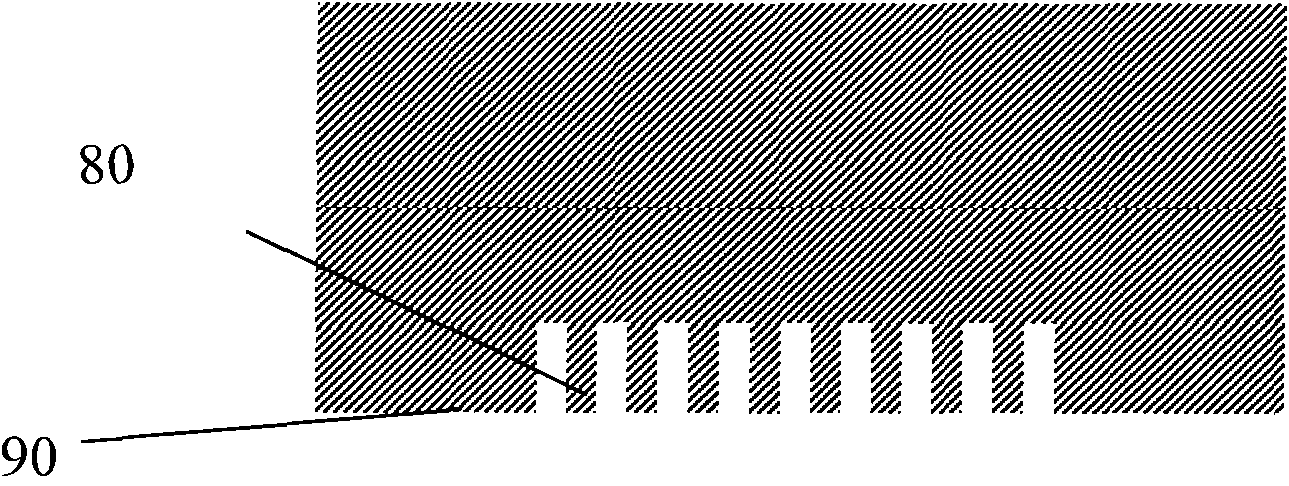

[0014] like Figure 1 to Figure 3 As shown, the manufacturing method of the alignment mark of the present invention includes two steps. First, photolithography is performed on the back surface 90 of the silicon wafer to etch a gate-shaped alignment mark. Secondly, a layer of oxide film 70 is deposited on the alignment mark. As a protective layer of the alignment mark, to prevent the alignment mark from being affected by other processes during the manufacturing process, the oxide film may be a silicon oxide film.

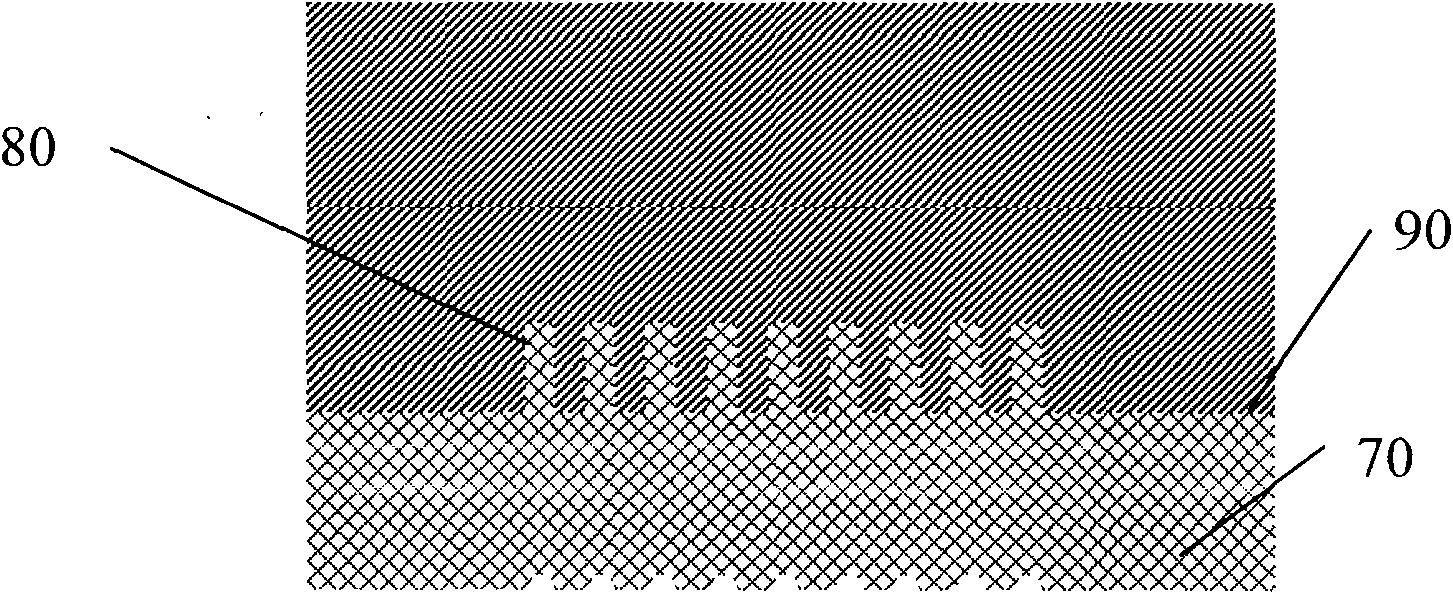

[0015] The alignment mark formed by the above method has a structure such as Figure 4 As shown, the alignment mark 80 is located on the back side 90 of the silicon wafer, and the alignment mark 80 is covered with an oxide film layer 70 that protects the alignment mark from being affected by other processes. The alignment mark of the present invention does not reduce the use of the front side of the silicon wafer. area.

[0016] like Figure 5 As shown, the detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com