Low pressure drop holding grid and fuel component with holding grid

A technology for maintaining grids and low pressure drop, applied in the field of nuclear reactors, can solve the problems of bad heat dissipation effect of fuel assemblies, large pressure loss of coolant fluid, etc., and achieve the effects of considerable material saving, small pressure loss, and reduction of the frontal flow area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

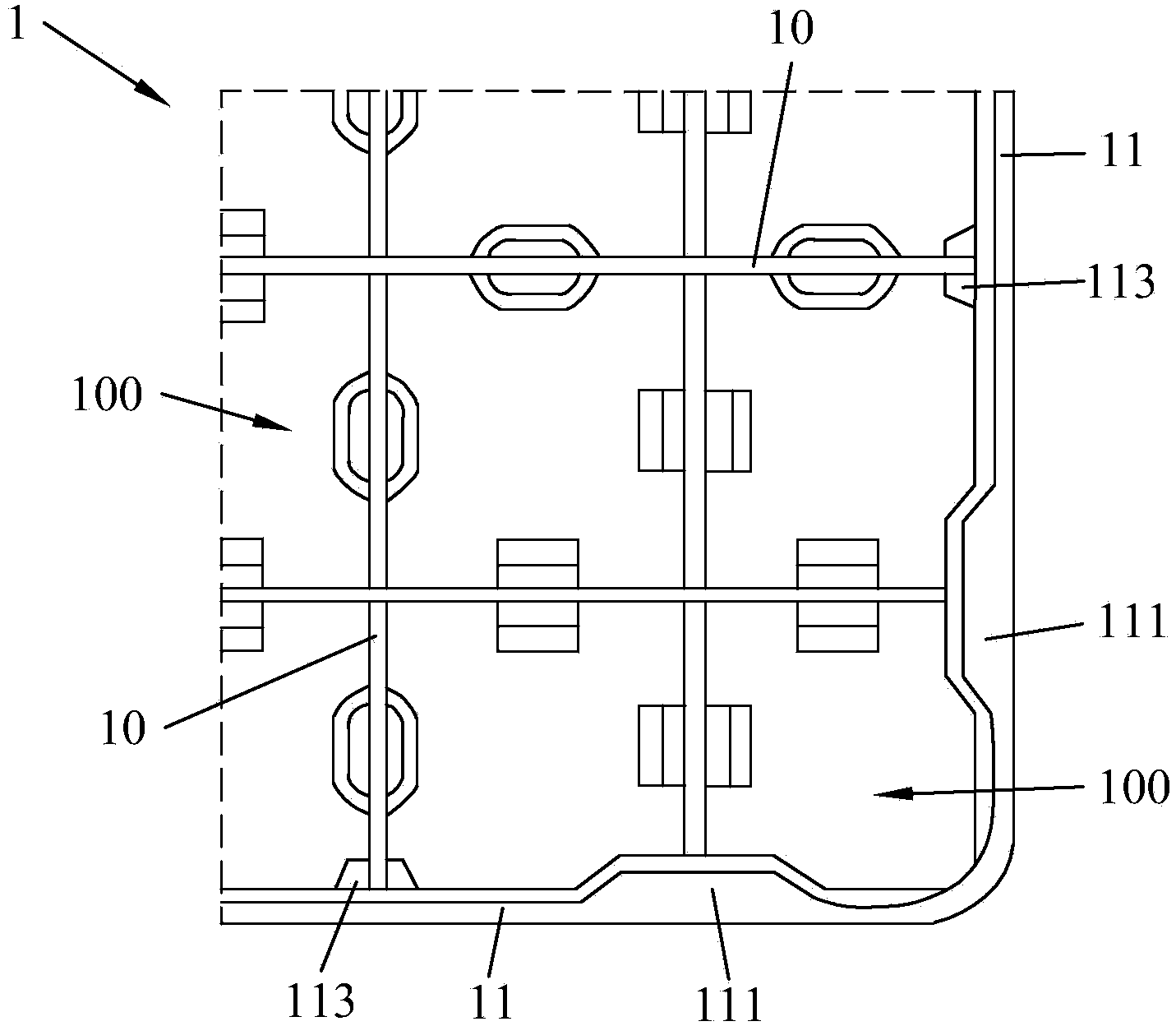

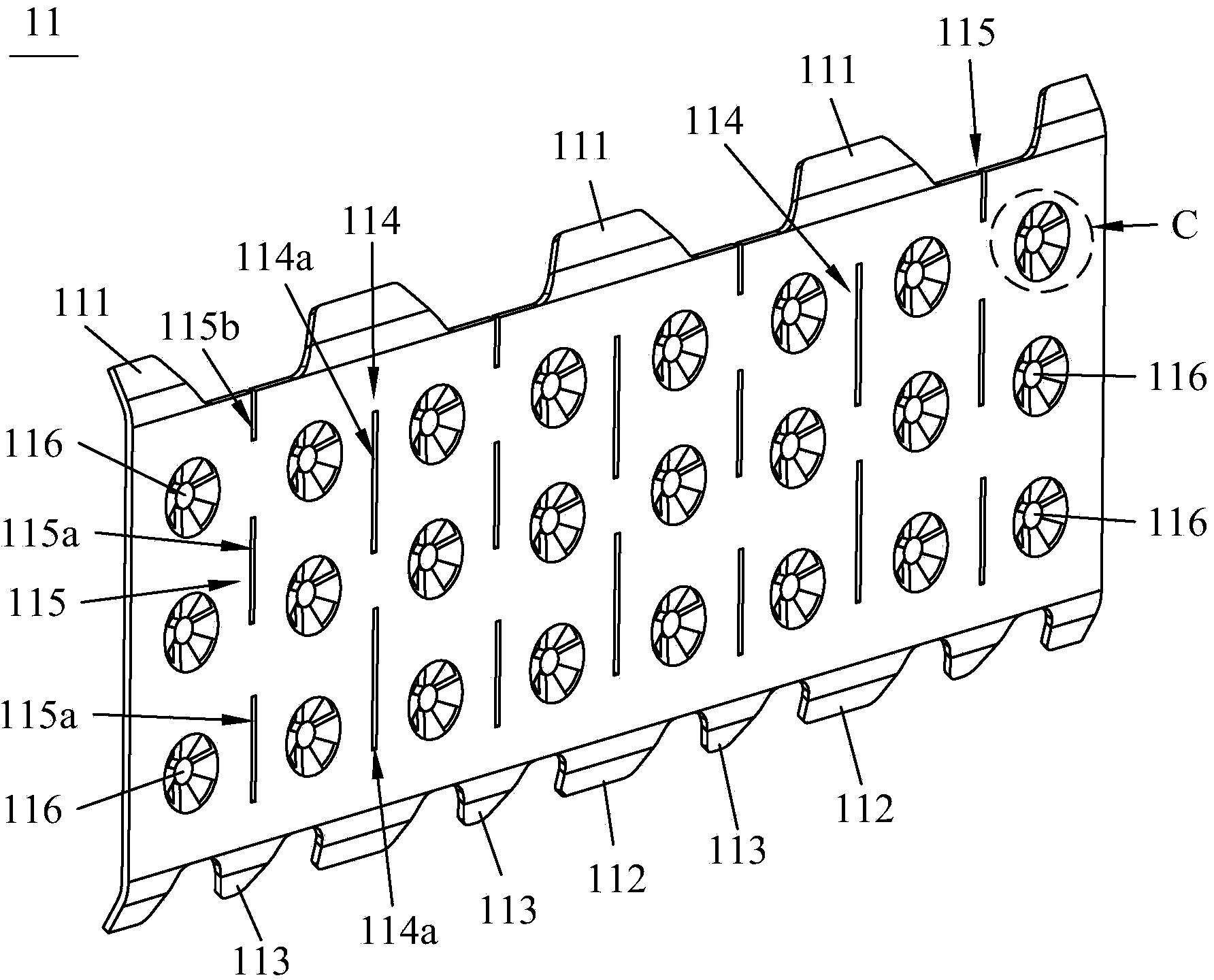

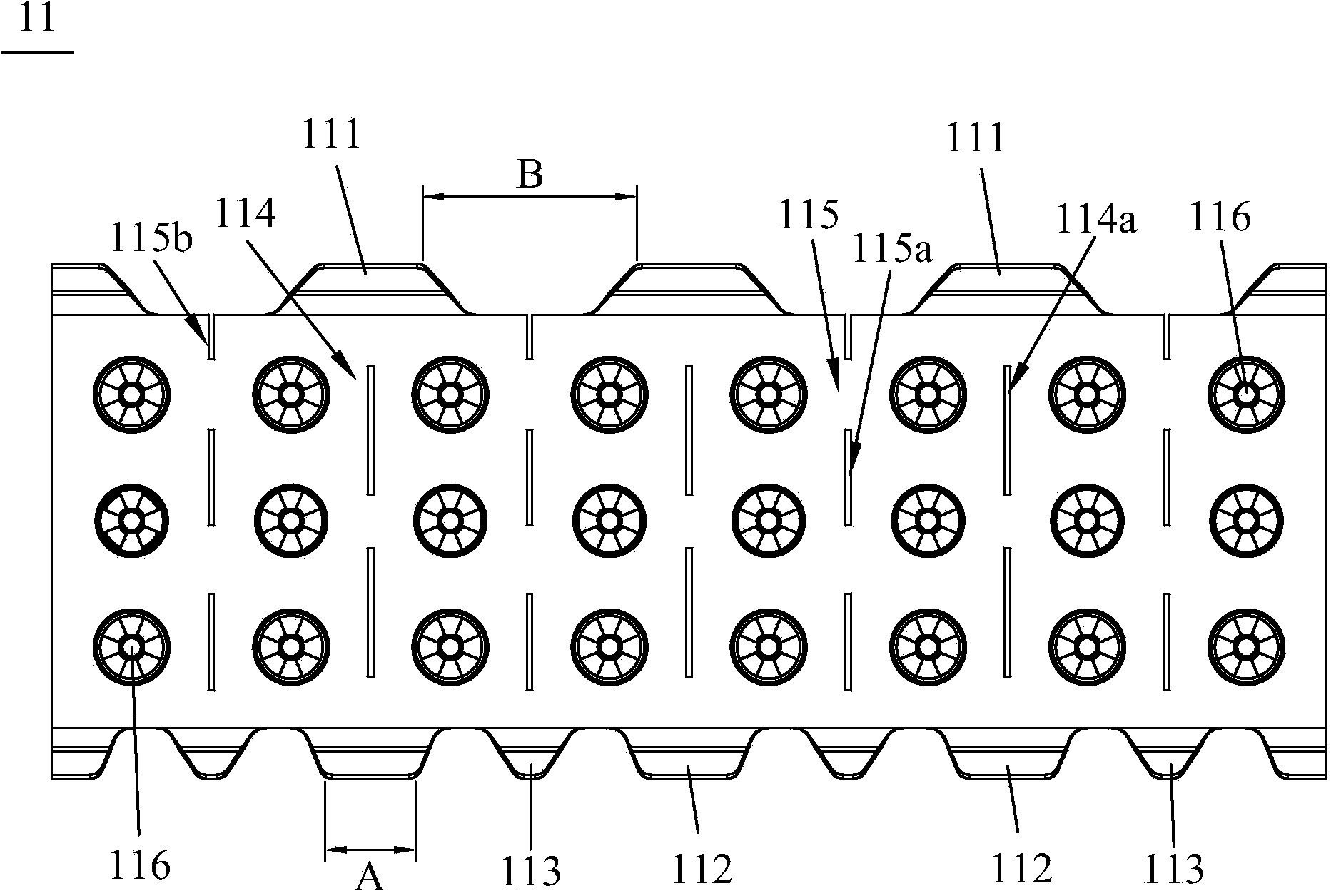

[0029] combine Figure 1 to Figure 3 As shown, the present invention provides a low-pressure drop holding grid 1 for light water reactor nuclear fuel assemblies, the holding grid 1 includes a plurality of inner strips 10 and outer strips 11, and a plurality of inner strips 10 cross each other to form a network The grid structure forms a plurality of hollow grid units 100 , and the outer strips 11 surround the grid structure and are fixed with the inner strips 10 . Except for a few grid units 100 which accommodate control rod guide tubes, most of the other grid units 100 accommodate a fuel rod. And the same rigid projections and springs as in the prior art can be set on the inner strip 10 to clamp the fuel rods.

[0030] The upper edge of the outer strip 11 forms a plurality of first guide wings 111 arranged at intervals, and the lower edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com