Self-optimizing combustion control method of blast-furnace hot blast stove

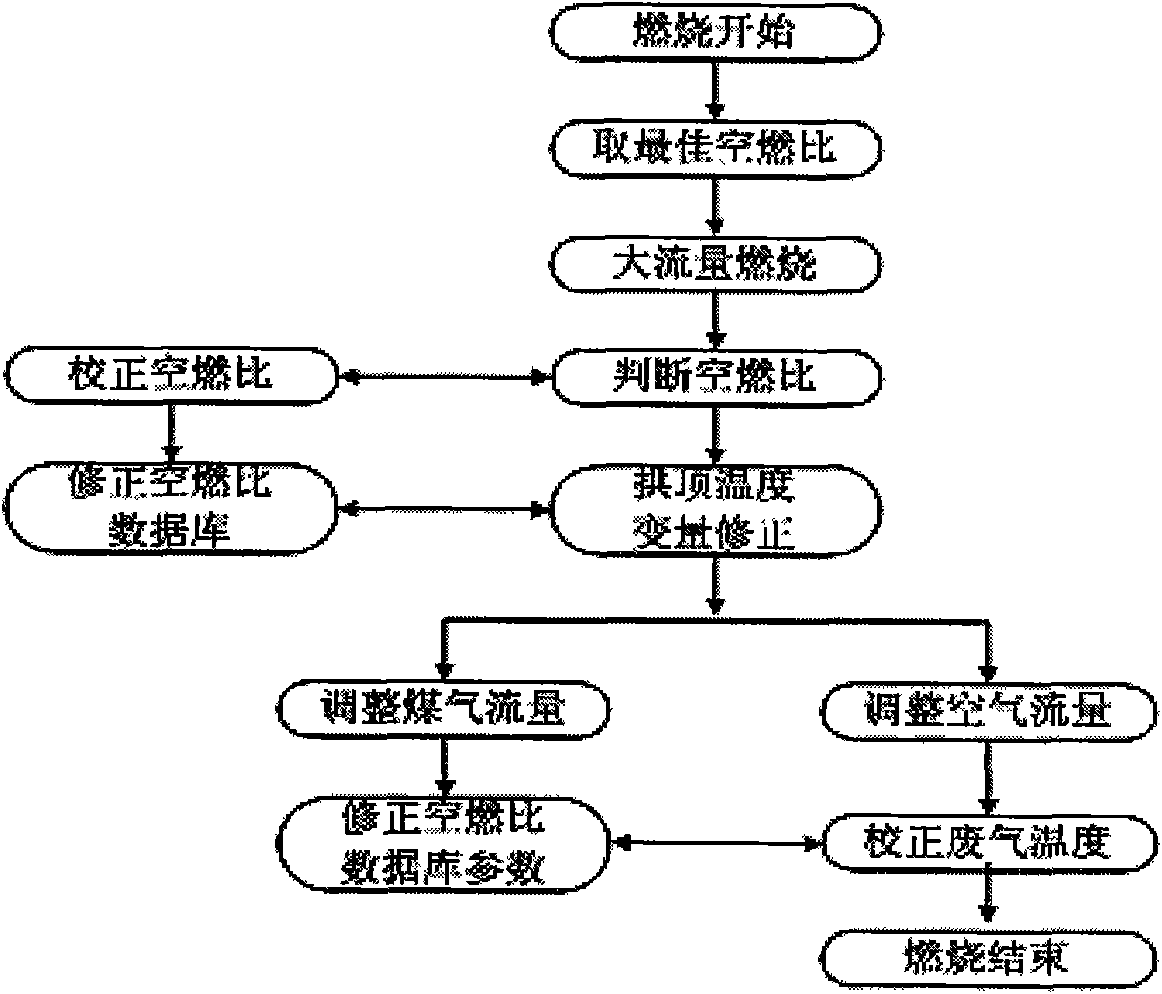

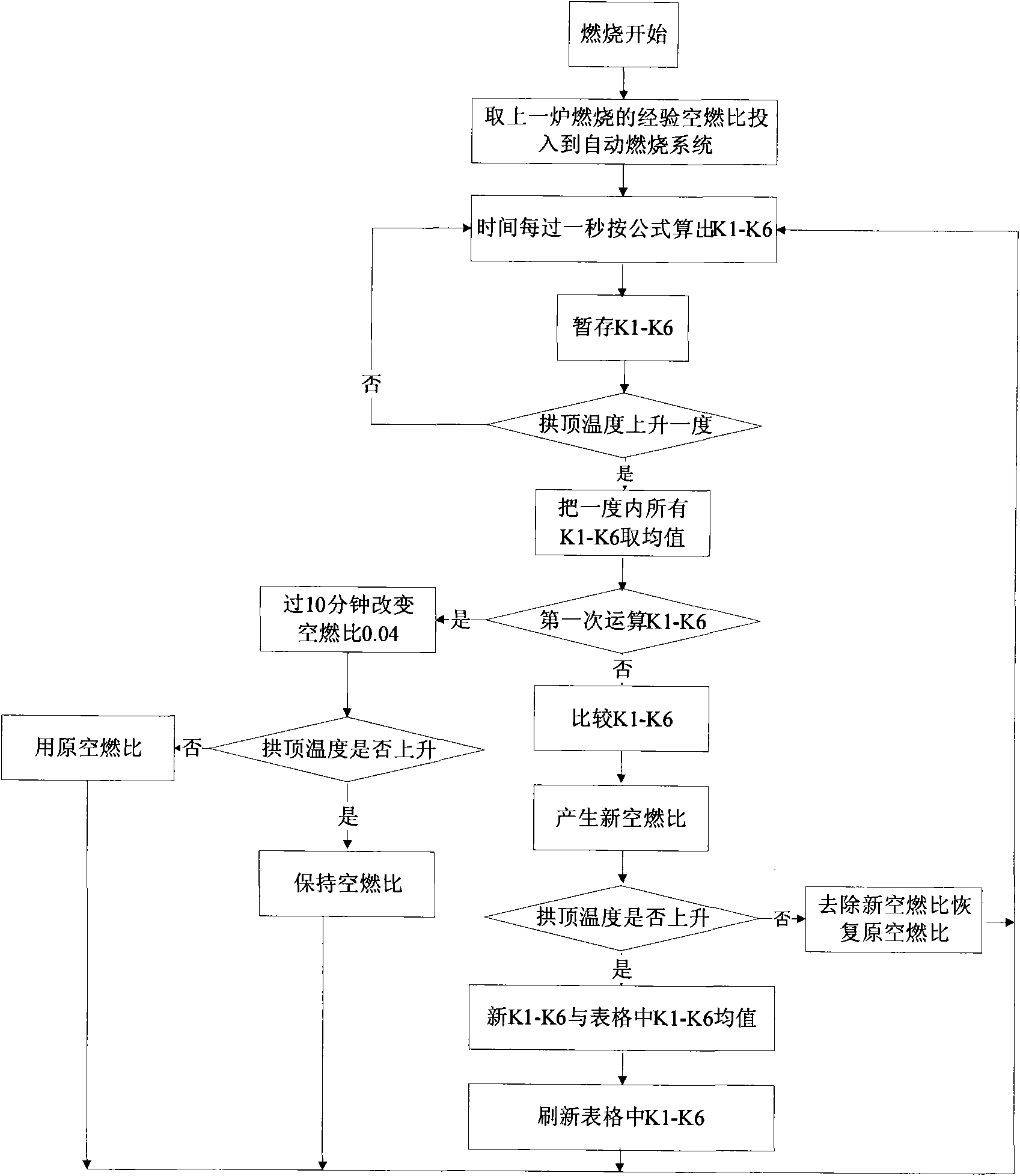

A control method and technology of a hot blast stove, applied in the direction of combustion method, combustion control, fuel supply adjustment, etc., can solve the problems of slow adjustment response, failure to meet the best air-fuel ratio accuracy, and unfavorable energy saving, etc., to achieve improved air temperature, Effects of prolonging life and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

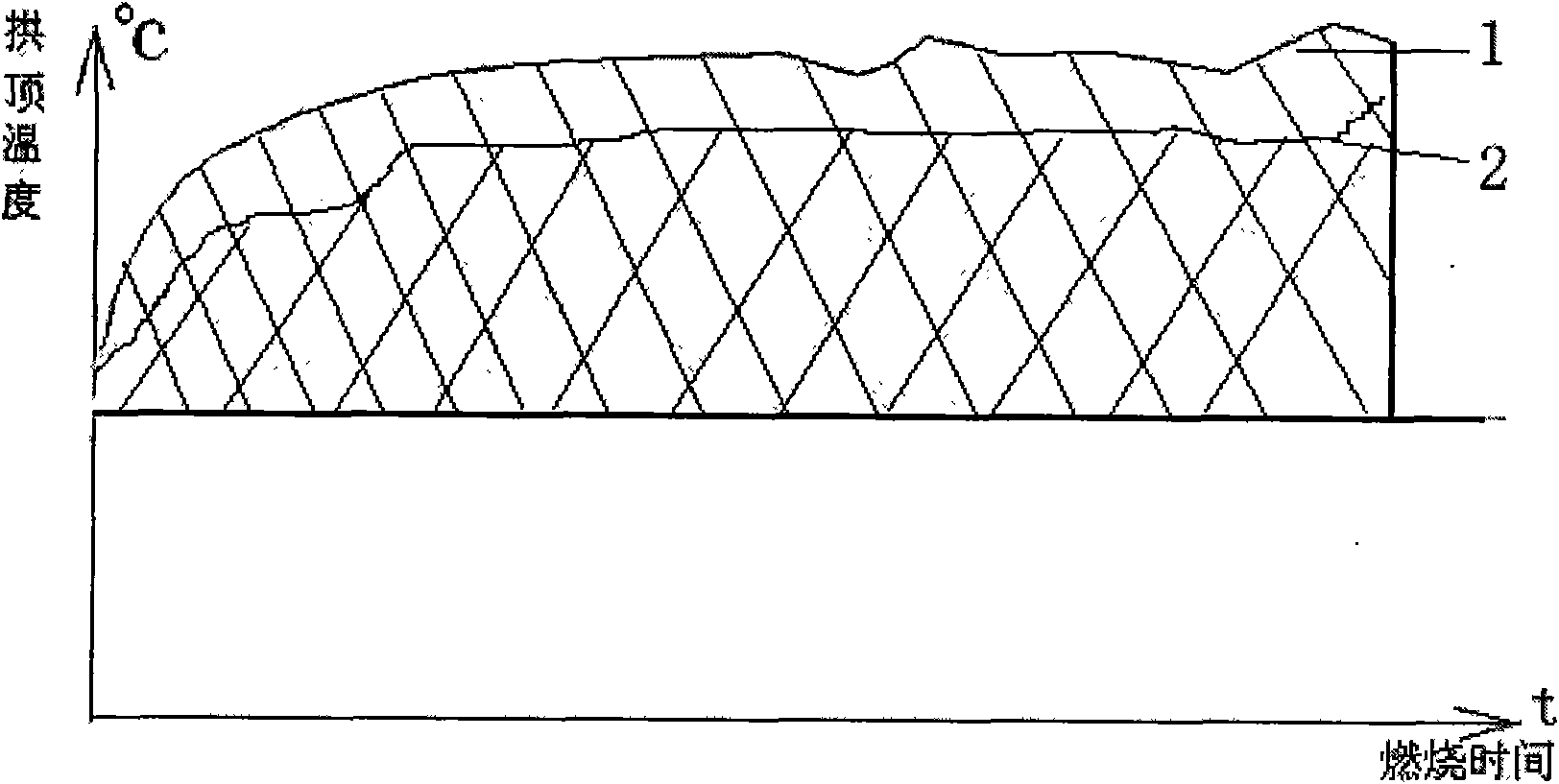

[0067] When the hot blast stove has been fired for 1800s (T), the time required to burn the hot blast stove once (T 0 )5400S, the current vault temperature (W) is 1210°C, the vault temperature in the first minute is 1209°C, the vault temperature starting point (Wn) is 1100°C, the gas pressure (P n ) 8.18KPa, gas pressure upper limit (P) 10KPa, current exhaust gas temperature 213.6°C, exhaust gas temperature 210.1°C in the first 1 minute, instantaneous gas flow average (QA) 1830m in the first 5 minutes 3 / min, air flow (QB) 800m 3 / min, air flow upper limit (Q) 1800m 3 / min, when the air-fuel ratio K participating in the control is 0.513 (this value is constantly replaced by the new air-fuel ratio calculated according to the following method), calculate a set of data of K1, K4, K6. The K1.K4.K6 sequence list generated in the last round is shown in Table 1:

[0068] Table 1

[0069] vault temperature

K1

K4

K6

1210

48.211

0.1317...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com