LED package module

A technology of LED packaging and LED chips, which is applied to lighting devices, components of lighting devices, cooling/heating devices of lighting devices, etc., and can solve problems such as high cost, delamination of printed circuits, and increased manufacturing costs of lighting devices

Inactive Publication Date: 2011-01-05

DONGGUAN WANFENG NANOMETER MATERIALS

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above-mentioned existing technologies still have deficiencies, which restrict the popularization and application of LED lighting technology.

One of the disadvantages of the above-mentioned prior art is that the aluminum substrate used in the above-mentioned technology is a common aluminum or aluminum alloy material on the market, and the processing performance of the aluminum material is poor, which will increase the manufacturing cost of the lighting device; although the thermal conductivity of aluminum or aluminum alloy It is acceptable, but its thermal expansion coefficient is as high as about 23*10-6 / K (0-100°C), which is more than 30% different from the thermal expansion coefficient of printed circuit materials and LED bulb electrodes, which does not meet the principle of thermal expansion coefficient matching, so the LED above When the lighting device is actually used, the printed circuit will be delaminated or broken, and it may cause the solder joints of the LED bulb to fall off or the chip soldering gold wire in the LED bulb to be disconnected, thereby causing the LED lighting device to malfunction.

The second deficiency of the above-mentioned prior art is that the heat dissipation effect is still not very satisfactory. The heat dissipation method of the existing LED lighting device is to emit light from the front and dissipate heat from the back; The bottom faces backward, and the substrate is made of materials with low thermal conductivity such as sapphire. The main heat is dissipated from the front or side, which is in contradiction with the heat dissipation on the reverse side of the LED lighting device. As a result, most of the heat stays in the LED bulb and cannot be dissipated in time. If it falls off, it is easy to cause the failure of the LED lighting device

The third disadvantage of the above-mentioned prior art is that secondary optical processing is required, which increases the difficulty of manufacturing, and the increased material also leads to an increase in the cost of the LED lighting device and an increase in the volume of the LED lighting device

Moreover, during the secondary optical processing, it will lead to loss of luminous flux and hinder heat dissipation

The fourth deficiency of the above-mentioned prior art is that the LED bulbs and LED chips used in it are set by silver glue, the amount of silver used is too little, and the thermal conductivity is not good; the amount of silver used is too large, the cost is high and the firmness is not good; Taking into account thermal conductivity and firmness

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

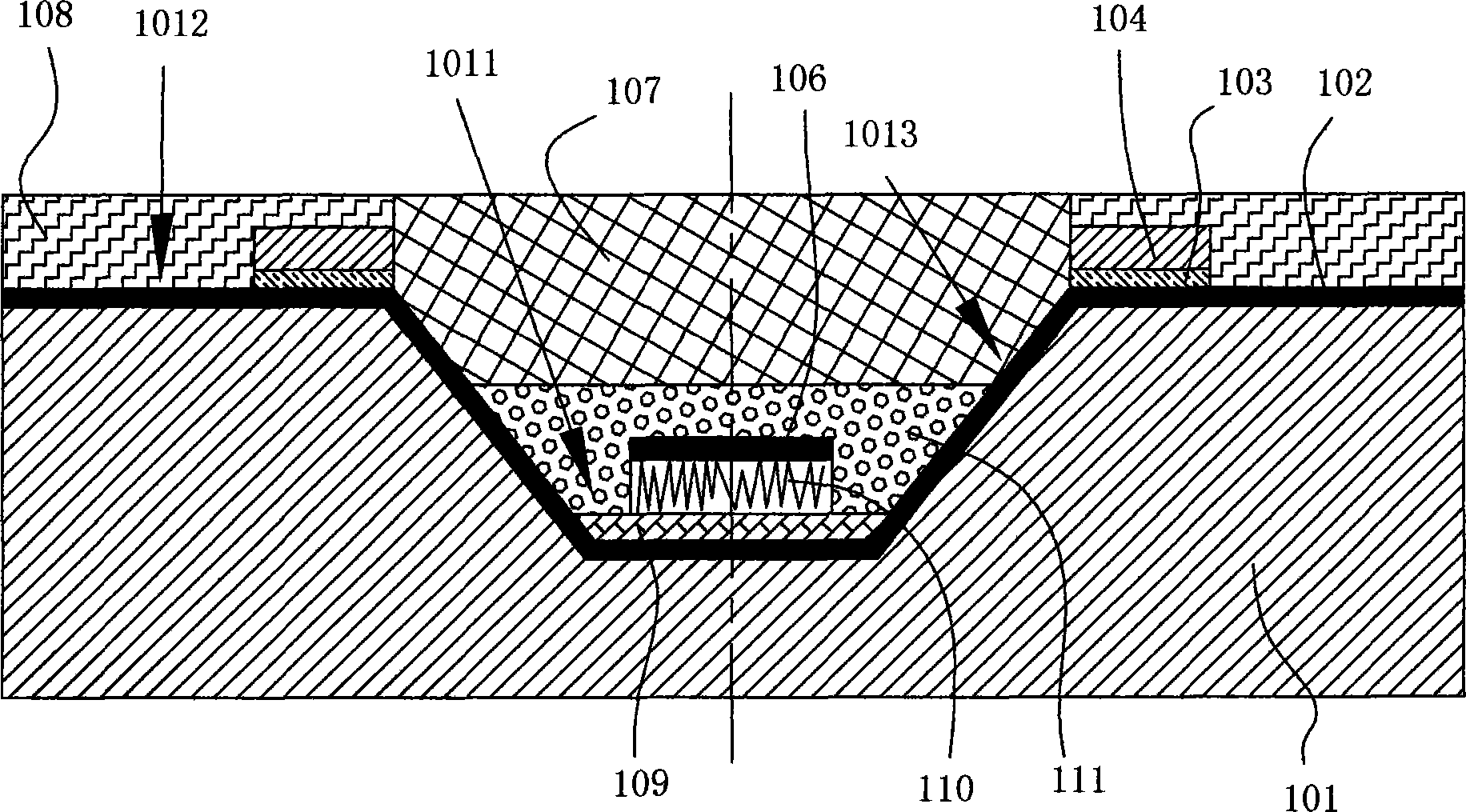

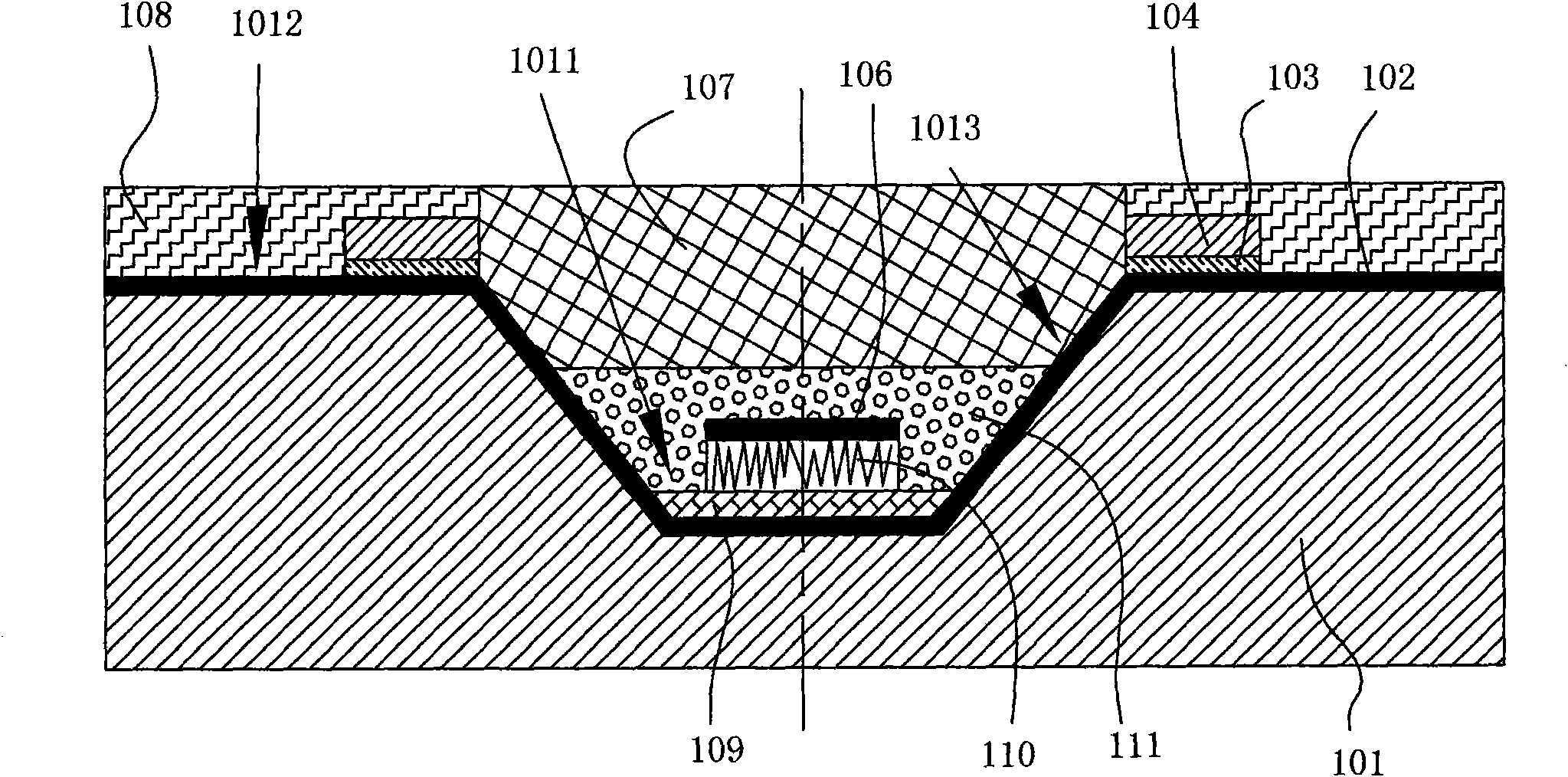

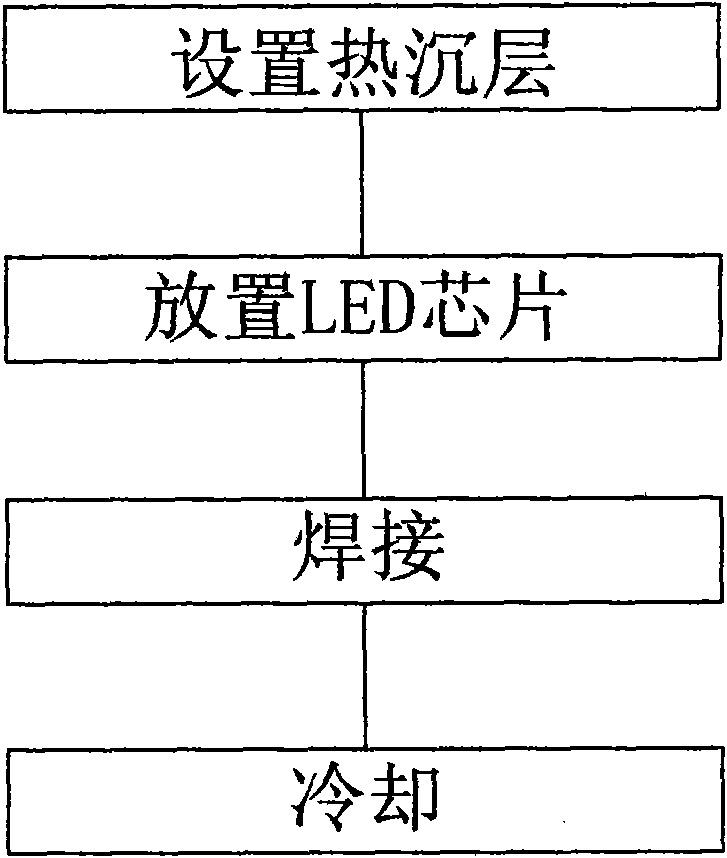

The invention relates to a lighting LED package, in particular to an LED package module, which comprises a substrate, wherein the substrate is provided with a die bonding surface and a wiring surface; the wiring surface is provided with a circuit part; the circuit part forms a circuit on the substrate and is arranged on a surface layer of the wiring surface; and the circuit part is provided with a layered structure and comprises a heat-conductive insulating adhesive layer and a conductive plating layer from inside to outside. The invention provides the LED package module of which a conductivelayer and the substrate are firmly combined and which has reliable work. The invention also provides a method for preparing the LED package module.

Description

LED package module technical field The invention relates to an LED package for lighting. Background technique Compared with traditional lighting devices, LED street lights not only have the characteristics of good chromaticity, maintenance-free, and long life, but more importantly, they are more energy-efficient than traditional street lights. Chinese invention patent document CN101101103A disclosed a LED street lamp on January 9, 2008, including a lamp body and an LED bulb. The lamp body includes a head section, a middle section, and a tail section. Section docking setting; there is a gasket between the head section and the middle section, and the head section is connected to the middle section through fasteners; there is a gasket between the tail section and the middle section, and the tail section is connected to the middle section through fasteners; the middle section is a The profile has the same cross-section at different positions along the length of the profile. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F21S2/00F21V19/00F21V7/22F21V23/00F21V5/08F21V29/00F21V9/10H01L23/373H01L25/075H01L33/00F21Y101/02F21K9/20F21V9/40F21V29/85F21Y115/10

CPCH01L2924/0002H01L2924/00

Inventor 李金明

Owner DONGGUAN WANFENG NANOMETER MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com