Gravity-type atmospheric dry chamber

A gravity-type, normal-pressure technology, applied in the field of dry tanks, can solve the problems of adding auxiliary components and equipment, increasing the difficulty of design and manufacturing, and prolonging the construction period, so as to shorten the maintenance period, shorten the installation time, and be safe and reliable in application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

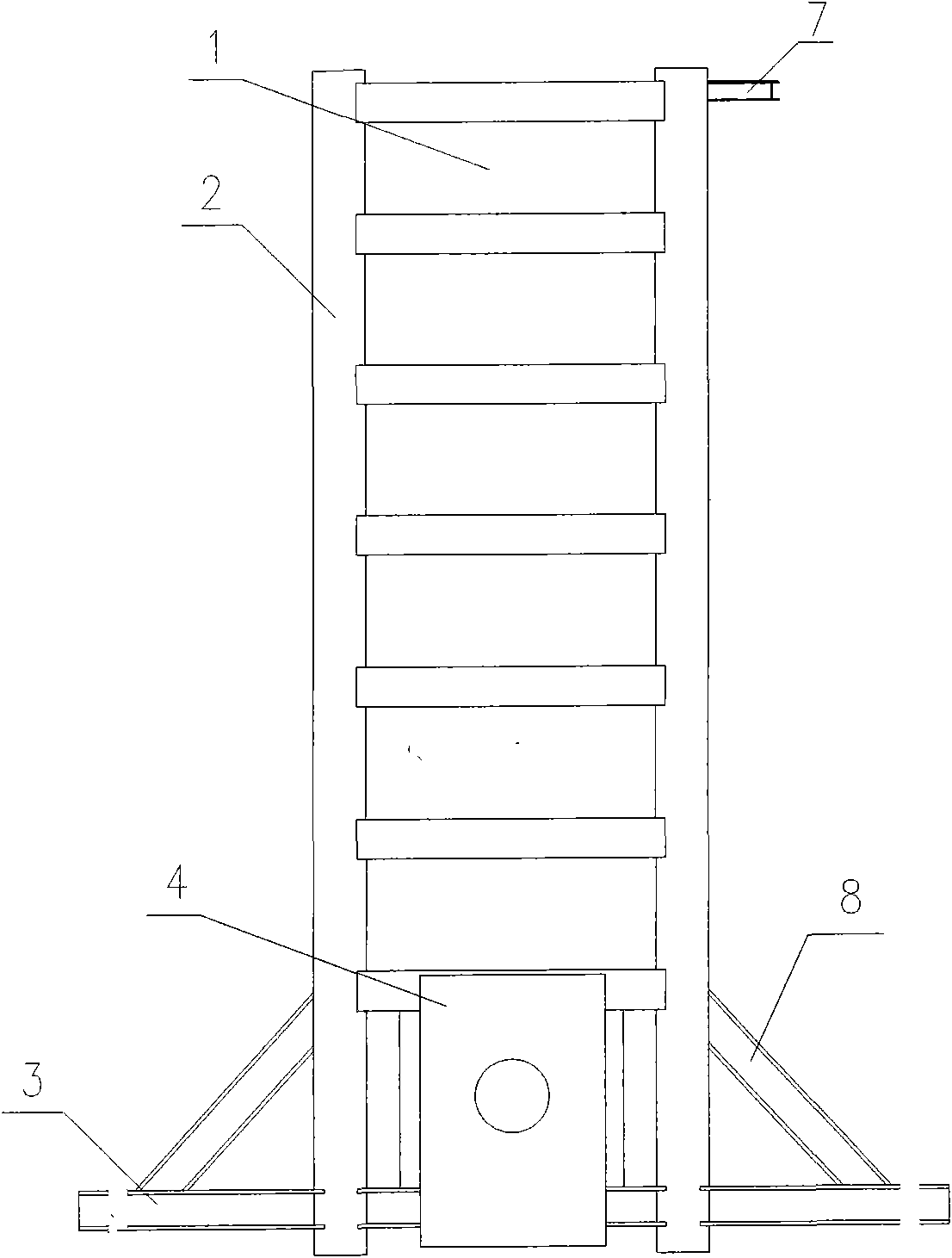

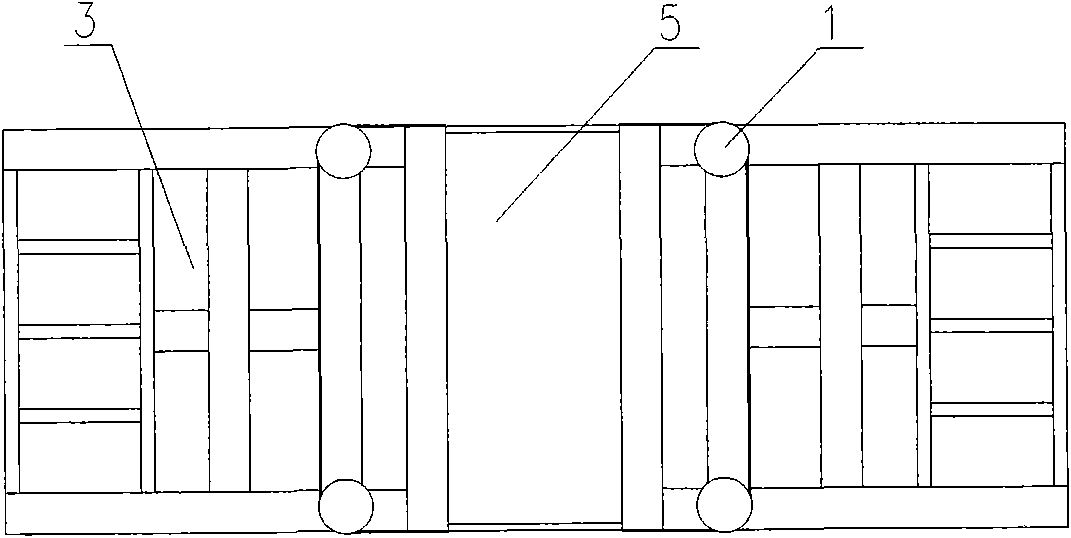

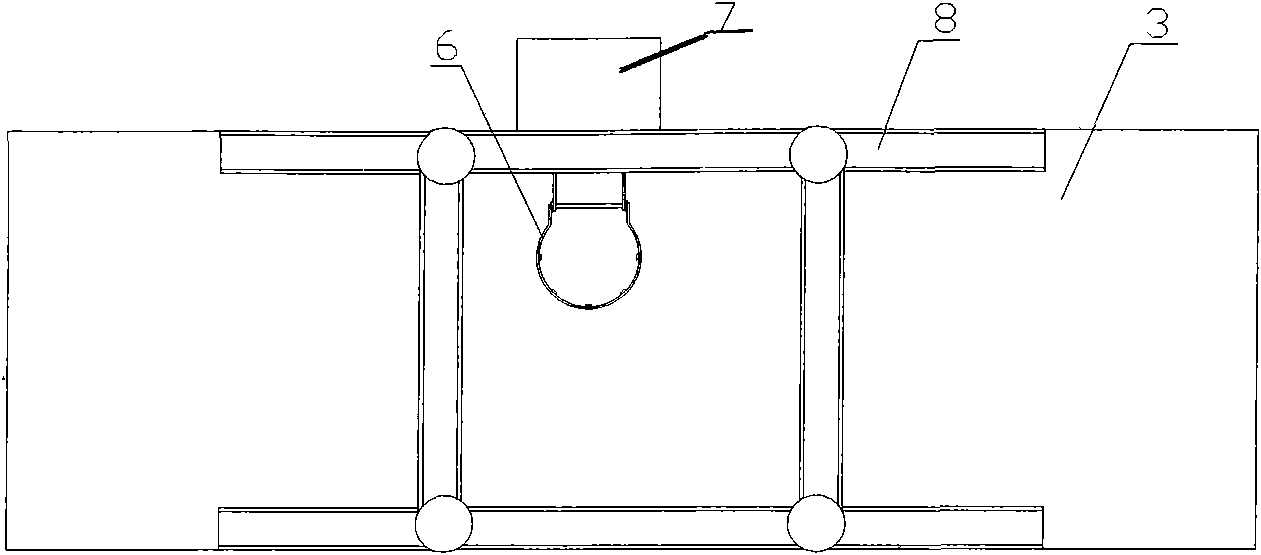

[0021] refer to Figure 1 ~ Figure 4 , the present invention's gravity-type normal-pressure dry cabin includes: cabin body 1, anti-settling plate 3, side sealing door 4 and bottom sealing door 5, and working cabin body 1 is mainly formed by butt-welding of conduit, I-beam, and steel plate to form an upper opening The box-shaped steel structure provides a dry working environment for pipeline repair operators. The front side of the cabin body 1 is provided with a side sealing door 4, the bottom of the cabin body 1 is provided with a bottom sealing door 5, and the lower end of the cabin body 1 is vertically arranged and connected with an anti-sinking plate 3 on both sides of the cabin body 1. A stiffener plate 8 is connected between the plate 3 and the cabin body 1, and a platform 7 is arranged and welded on the top of the cabin body 1, and the platform 7 is a steel structure block.

[0022] The interior of the cabin of the cabin 1 is equipped with an escalator 6 that allows rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com