Method for color retouching of cotton knitted fabric on forming machine

A cotton knitting and setting machine technology, applied in dyeing, fabric surface trimming, textiles and papermaking, etc., can solve the problems of cost increase, damage, troublesome repairs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

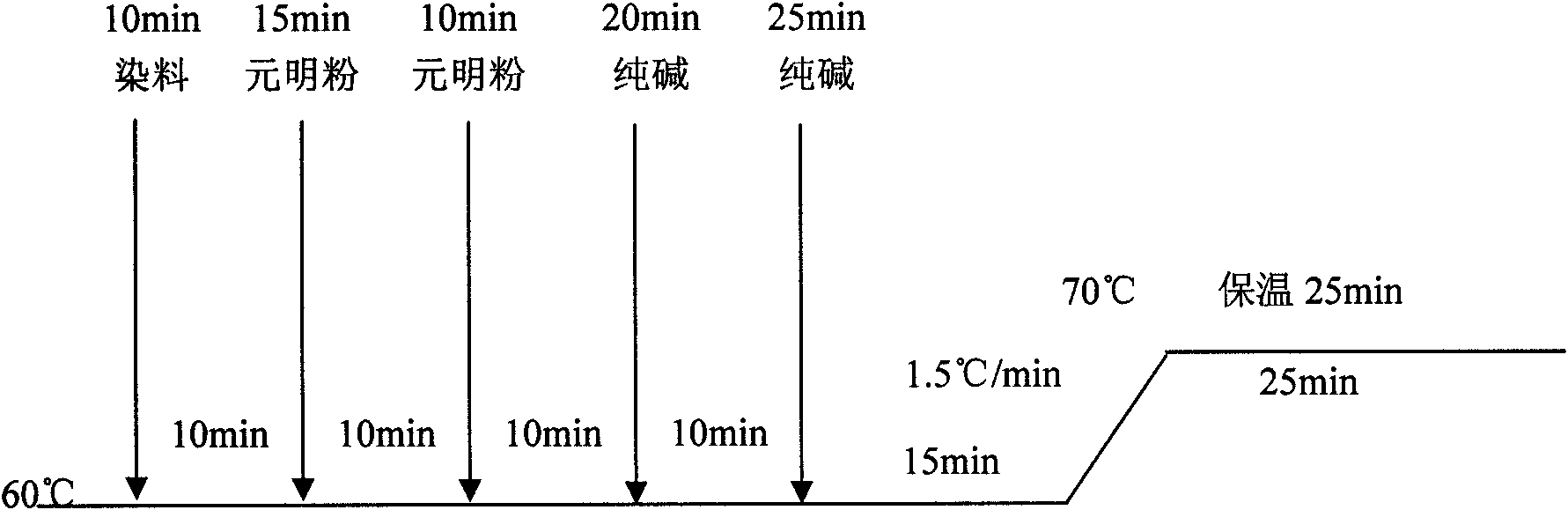

Method used

Image

Examples

Embodiment 1

[0102] Gray fabric specification: 300 grams of CVC brushed fleece

[0103] Fabric color: navy blue

[0104] Reason for repairing gray fabric: light color

[0105] Repair solution formula:

[0106] M-2GE Blue 0.6g / L

[0107] M-3BE red 0.45g / L

[0108] M-3RE yellow 0.22g / L

[0109] Penetrant 1g / L

[0110] Yuanming powder 10g / L

[0111] Soda ash 5g / L

[0112] When repairing the color, prepare the repair solution according to the above ratio, generally use a uniform small padding car, one dipping and one rolling the gray cloth rolling rate is 75%, the padding temperature is 30°C-40°C, and bake on the setting machine for 90 seconds. 150°C, then control the temperature at 50°C and wash with water for 10 minutes. Finally, after drying, napping, and setting, use the ORINTEX color measurement system for color matching. The color difference is 4-5 after testing. The washing fastness is tested according to GB / P3921-2008. The color fastness to cotton staining is grade 4, which is ...

Embodiment 2

[0114] Gray fabric specification: 300 grams of CVC brushed fleece

[0115] Fabric color: silver gray

[0116] The reason for the repair of the gray cloth: the color is blue

[0117] Repair solution formula:

[0118] M-2GE Blue 0.03g / L

[0119] M-3BE red 0.02g / L

[0120] M-3RE Yellow 0.02g / L

[0121] Penetrant 1g / L

[0122] Yuanming powder 10g / L

[0123] Soda ash 5g / L

[0124] Others are the same as embodiment one.

Embodiment 3

[0126] Gray fabric specifications: 270 grams of cotton spandex terry cloth

[0127] Fabric color: brown

[0128] Reason for repair: yellowish color

[0129] Repair solution prescription:

[0130] M-2GE Blue 0.02g / L

[0131] M-3BE red 0.01g / L

[0132] M-3RE Yellow 0.04g / L

[0133] Penetrant 1g / L

[0134] Yuanming powder 5g / L

[0135] Soda ash 3g / L

[0136] Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com