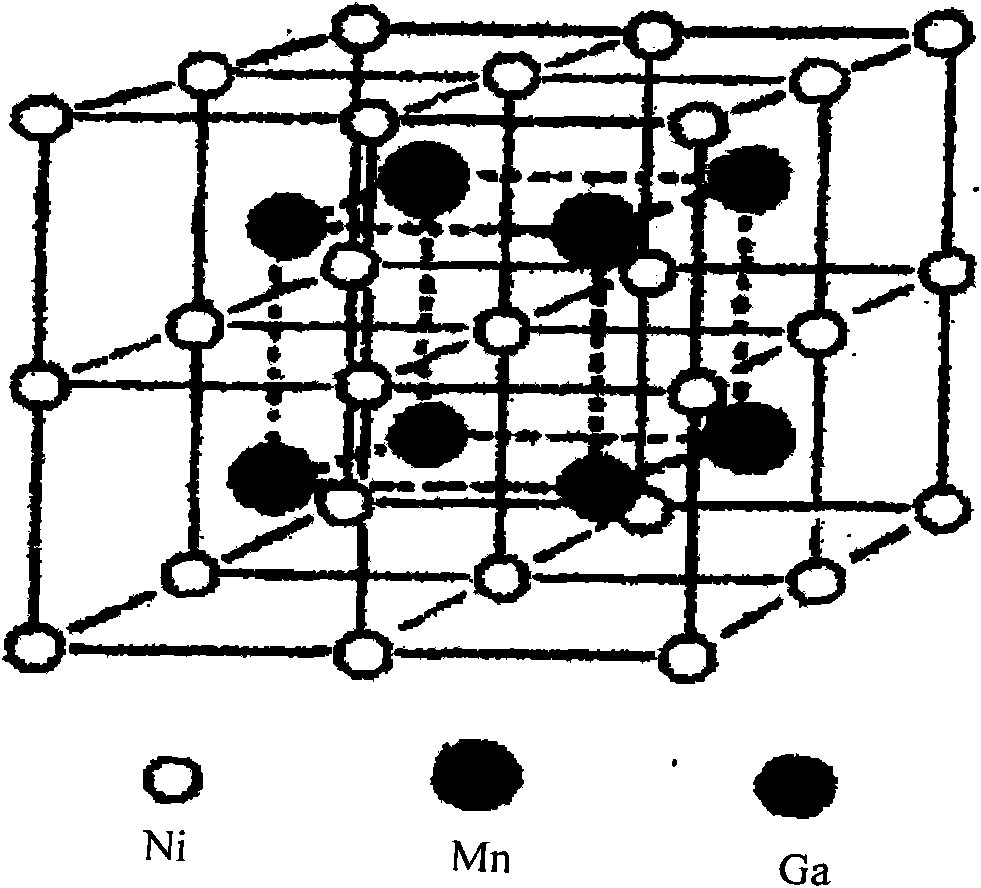

Preparation of Ni-Mn-Ga magnetic shape memory alloy by reduction-diffusion method

A memory alloy, nickel-manganese-gallium technology, applied in the new material field of shape memory materials, can solve the problems of unstable alloy performance, high equipment requirements, difficult processing, etc., and achieve stable and controllable composition, no environmental pollution, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

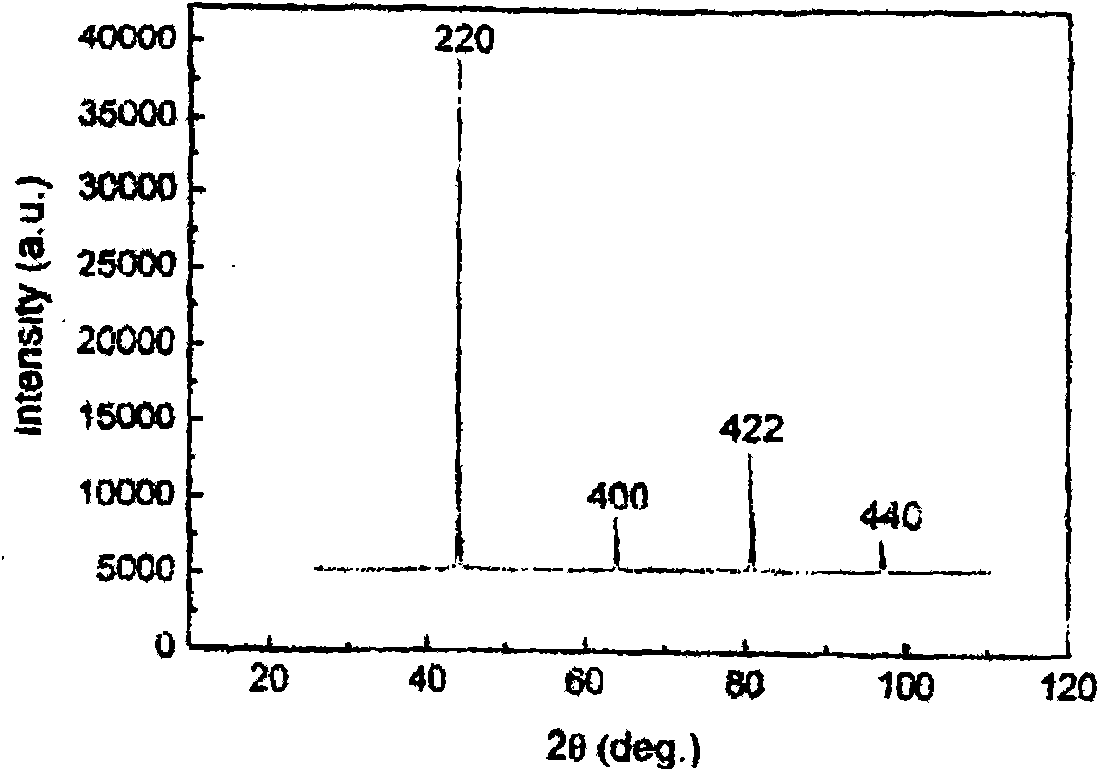

Embodiment 1

[0040] Mix 1000 grams of nickel powder, 474 grams of manganese powder, 721 grams of gallium oxide, 500 grams of Ca particles, and 680 grams of NaCl with a mixer for 1.5 hours, then use a 500Kg / cm 2 Press the sample into a ring-shaped block, put it into the reactor, and place it in a resistance heating furnace. After vacuuming to 2Pa, fill it with Ar gas to a positive pressure of 1.05MPa, and heat it to 950 under the protection of Ar gas. ℃, keep warm for 10 hours, then cool down to below 60 ℃ with the furnace, control at 30-60 ℃, take out the sample and place it in 5% NH by weight4 Soak in Cl aqueous solution for 6 hours, wash with water under agitation until the solution is brown, then wash with 2% (volume) acetic acid aqueous solution and 1% EDTA ammonia solution for 2 times, wash with water until the solution is neutral (pH value), and then filter. Rinse and filter twice with absolute ethanol, and then vacuum dry for 1 hour to obtain 2010 grams of alloy powder, containing 49...

Embodiment 2

[0046] 1000 grams of nickel powder, 474 grams of manganese powder, 721 grams of gallium oxide, 500 grams of Ca particles, CaCl 2 680 grams, after mixing uniformly with a mixer for 3 hours, use 800Kg / cm 2 Press the sample into a ring-shaped block, put it into the reactor, and place it in a resistance heating furnace. After vacuuming to 2Pa, fill it with Ar gas to a positive pressure of 1.25MPa, and heat it to 1100 under the protection of Ar gas. ℃, keep it warm for 7 hours, then cool down to below 60℃ with the furnace, control it at 30-60℃, take out the sample and place it in 10% NH by weight 4 Soak in Cl aqueous solution for 7 hours, wash with water under agitation until the solution is brown, then wash with 2% (volume) acetic acid aqueous solution and 1% EDTA ammonia solution for 2 times, wash with water until the solution is neutral (pH value) and then filter. Rinse and filter twice with absolute ethanol, and then vacuum-dry for 2 hours to obtain 2008 grams of alloy powder,...

Embodiment 3

[0049] 1000 grams of nickel powder, 474 grams of manganese powder, 721 grams of gallium oxide, 500 grams of Ca particles, MgCl 2 680 grams, after mixing uniformly with a mixer for 4 hours, use 600Kg / cm 2 Press the sample into a ring-shaped block, put it into the reactor, and place it in a resistance heating furnace. After vacuuming to 2Pa, fill it with Ar gas to a positive pressure of 1.15MPa, and heat it to 980 under the protection of Ar gas. ℃, keep it warm for 9 hours, then cool down to below 60℃ with the furnace, control it at 30-60℃, take out the sample and place it in 6% NH by weight 4 Soak in Cl aqueous solution for 5 hours, wash with water under agitation until the solution is brown, then wash twice with 4% (volume) acetic acid aqueous solution and 1% EDTA ammonia solution, and filter until the solution is neutral (pH value). Rinse and filter twice with absolute ethanol, and then vacuum-dry for 2 hours to obtain 2011 grams of alloy powder, containing 49.61% Ni, 23.58%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com