Bumper of track crane

A crane and rail technology, which is applied in the field of improvement of the buffer structure, can solve the problems of large floor space, high installation requirements, poor reliability, etc., and achieves the effects of reliable braking performance, few components, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

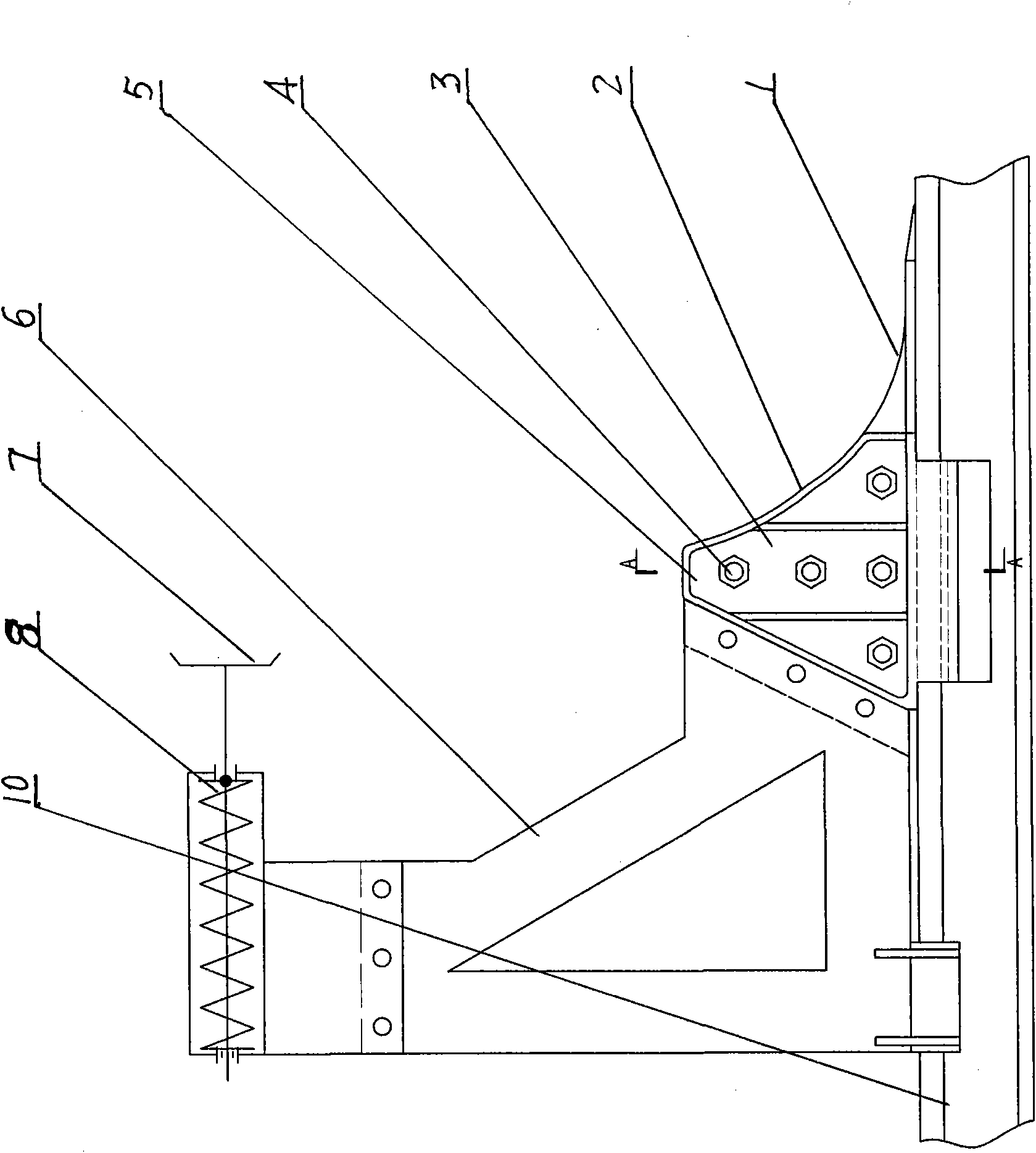

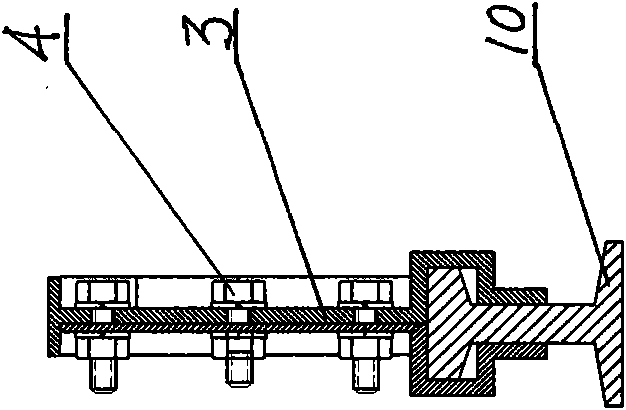

[0012] The present invention comprises support frame 6, and the front portion of support frame 6 is baffle plate 5, and the bottom of baffle plate 5 is made of two splints 3 that can fix rail 10, is fixed by screw 4 between splint plate 3; The arc surface 2 is consistent with the transition plate arc surface 1 which can be combined with the top surface of the rail 10 .

[0013] A spring damper 8 can be arranged above the support frame 6 , and the front of the spring damper 8 is the contact plate 7 . Before the crane slides forward and hits the baffle plate 5, it hits the contact plate 7 earlier, and the spring damper 8 can offset a part of the impact force of the crane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com