Hydraulic roller crusher

A hydraulic and crusher technology, which is applied in the direction of grain processing, etc., can solve the problems of limitation and occupying a large area, and achieve the effects of prolonging life, facilitating maintenance, and saving display space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the drawings and specific embodiments.

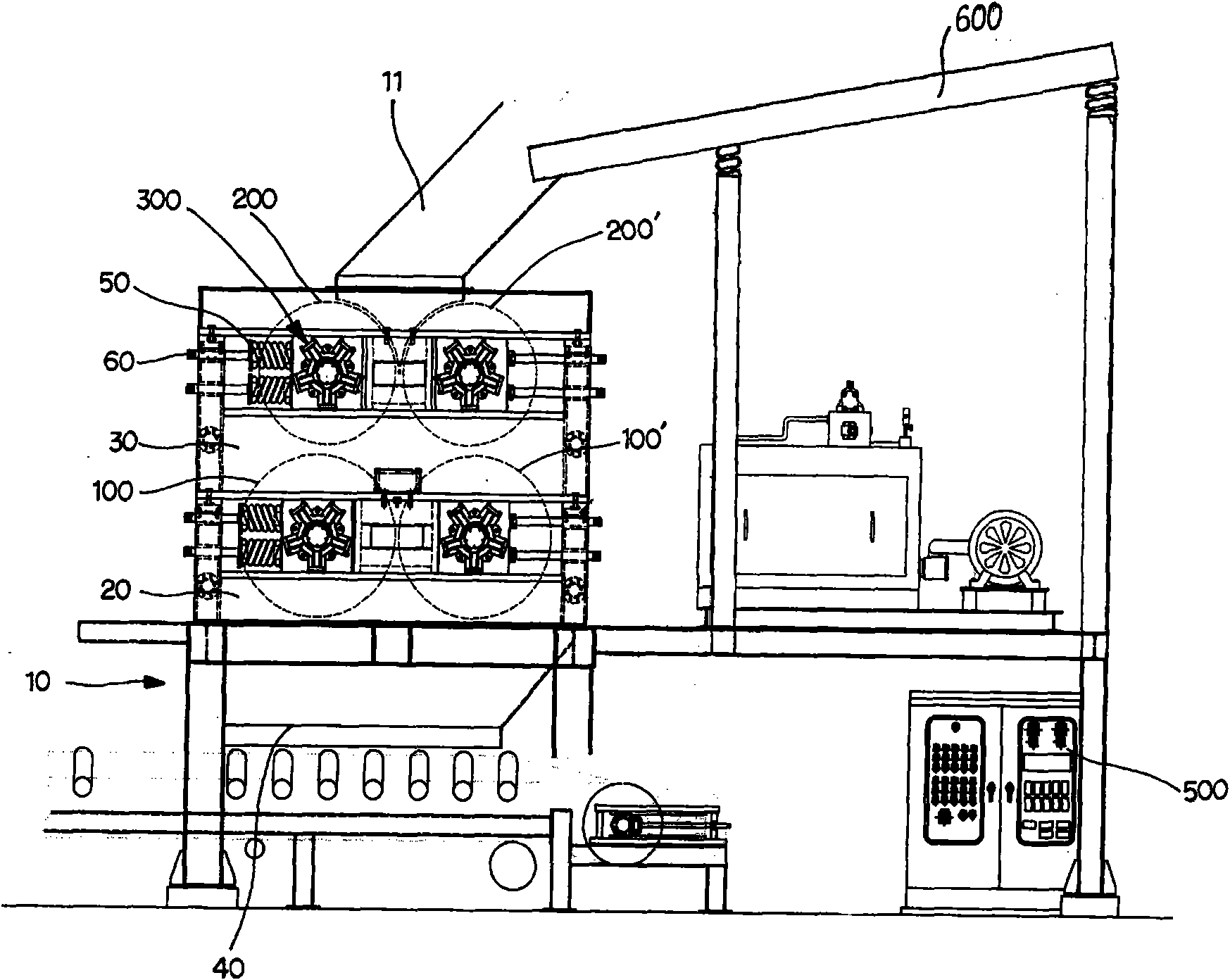

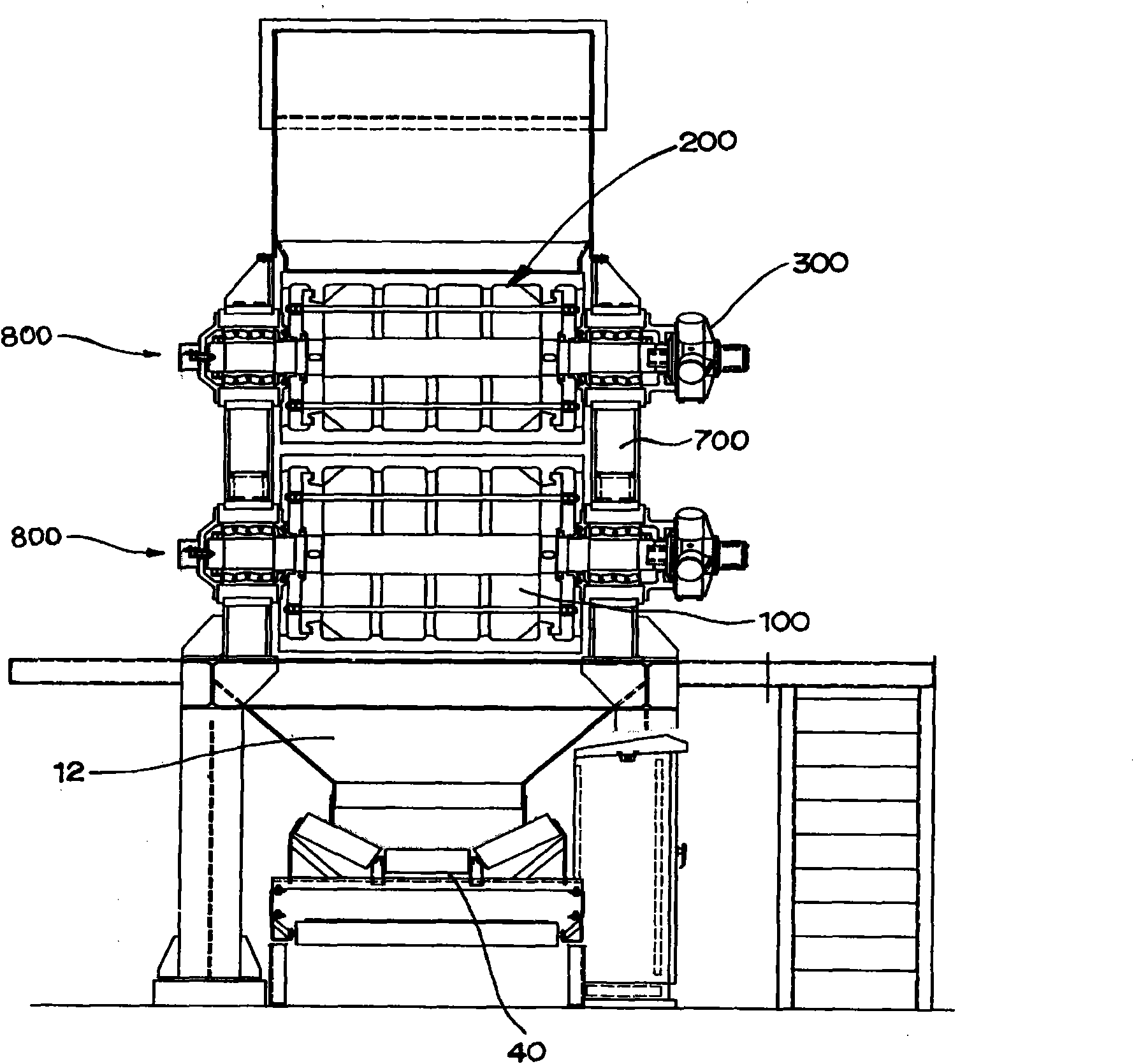

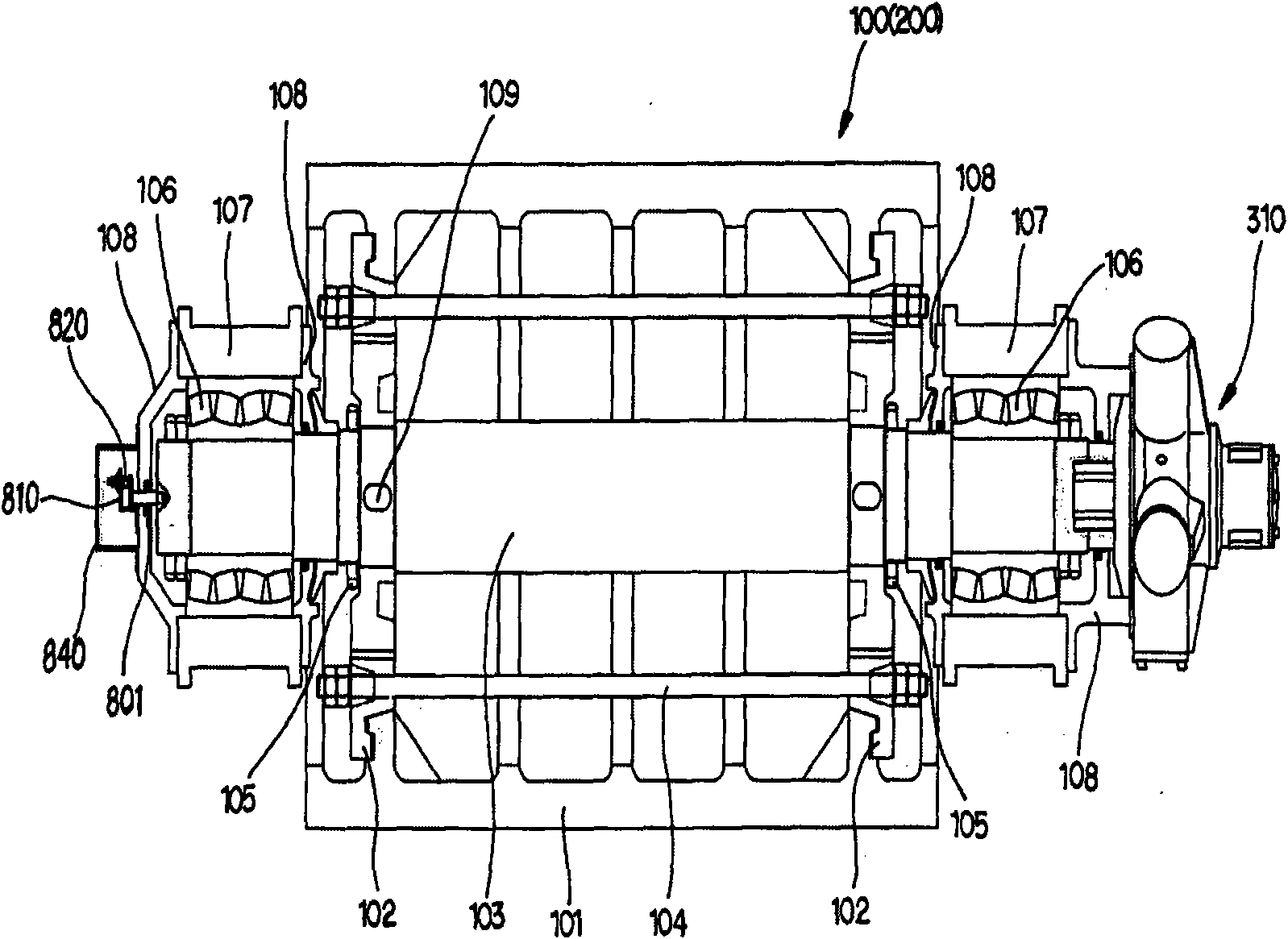

[0054] Such as Figure 1 to Figure 9 As shown, the hydraulic roller crusher includes a mechanical body (10) that supports or configures all mechanical devices. The first working surface (20) and the second working surface are connected to the above-mentioned mechanical body (10). (30), a pair of first and second roll crushing working surfaces (100) (200) installed on the first and second working surfaces (20) (30) are set on each of the above-mentioned shaft-shaped crushing working surfaces (100) (200) A hydraulic drive device (300) at one end, a gap adjustment device (400) that adjusts the gap between the crushing work surface of the first roll and the gap between the crushing work surface of the second roll, and a monitoring device that detects the speed of the hydraulic drive (300) (800), adjust the control device (500) of the aforementioned detection equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com