Process for production of thermally expandable beads and application thereof

A technology of heat-expandable microspheres and thermoplastic resins, which is applied in the direction of microsphere preparation, microcapsule preparation, transportation and packaging, etc. It can solve the problems of poor durability and no durable hollow particles, and achieve excellent durability.

Active Publication Date: 2010-03-24

MATSUMOTO YUSHI SEIYAKU

View PDF8 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As described above, although the durability of hollow fine particles to repeated compression has been studied in various ways, hollow fine particles with sufficiently improved durability to repeated compression have not been prepared.

The hollow fine particles obtained by thermally expanding the heat-expandable microcapsules described in Patent Document 3 are also poor in durability against repeated compression

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0079]

[0080]

[0081]

[0082]

[0083]

[0084]

[0085]

[0086]

[0087]

[0088]

[0089]

[0090]

[0091]

[0092]

[0093]

[0094]

[0095]

Embodiment A1

[0096]

Embodiment A2 to A18 and comparative example A1 to A8

[0097]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

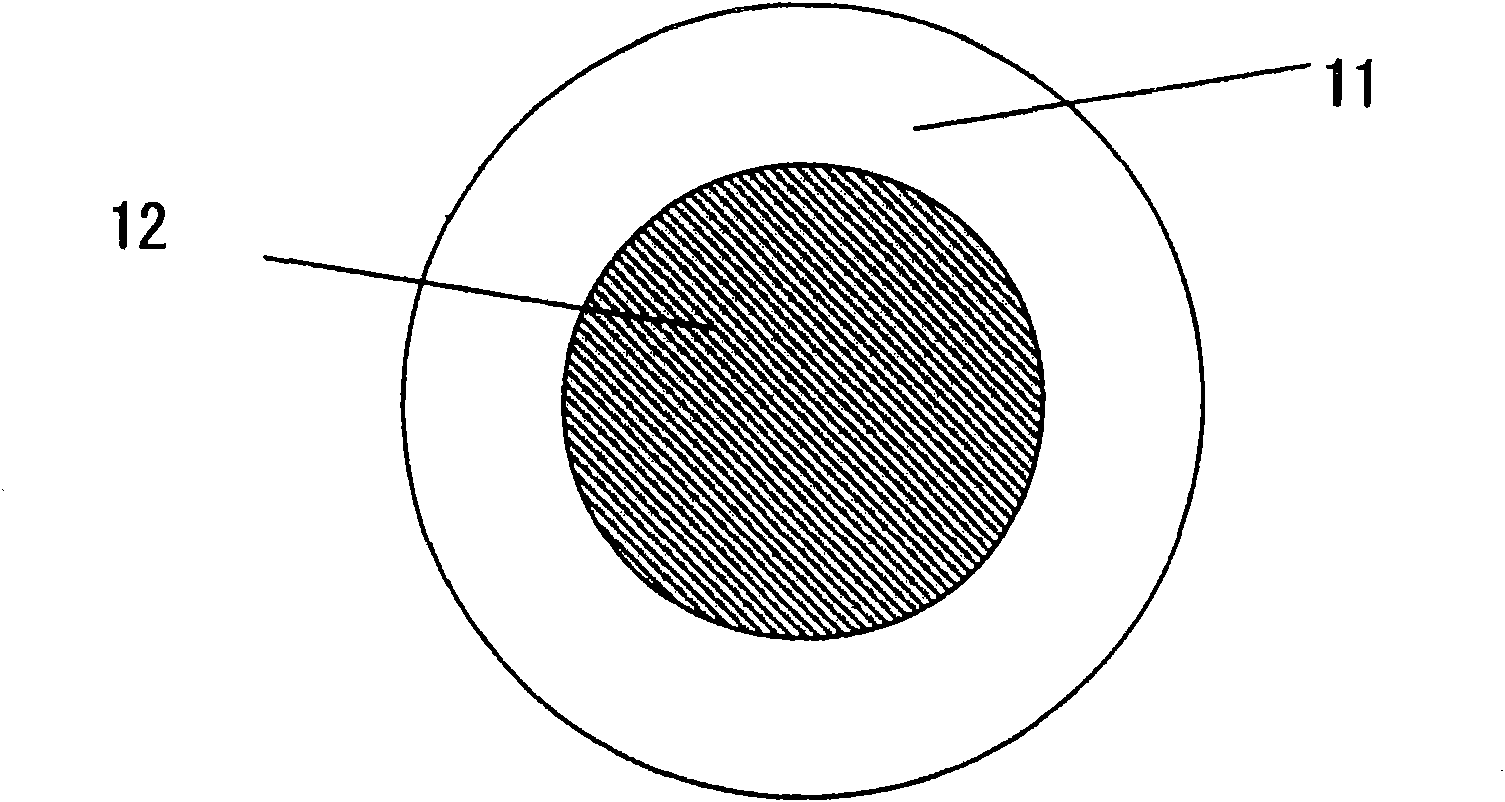

The invention provides a process for the production of thermally expandable beads which exhibit a high expansion ratio and give hollow fine particles excellent in the resistance to repeated compression through thermal expansion and application thereof. A process for the production of thermally expandable beads which are each constituted of both a shell made of a thermoplastic resin and a blowing agent that is enveloped in the shell and has a boiling point not higher than the softening point of the thermoplastic resin, which comprises the step of polymerizing a polymerizable component in an aqueous medium where the polymerizable component and the blowing agent are dispersed in the presence of an oxygen-containing aluminum salt and / or a hydrate thereof and at least one water-soluble compoundselected from among polyalkylene imines which have molecular weights of 1000 or above and each bear at least one structure constituted of an alkyl group substituted with a hydrophilic functional group selected from between carboxylic acid (salt) group and phosphonic acid (salt) group and a nitrogen atom attached to the alkyl group.

Description

technical field [0001] The invention relates to a preparation method and application of heat-expandable microspheres. Background technique [0002] Heat-expandable microspheres have a structure including a shell of a thermoplastic resin and a blowing agent enclosed in the shell, and are generally called heat-expandable microcapsules. Thermoplastic resins generally include vinylidene chloride-based copolymers, acrylonitrile-based copolymers, and acrylic-based copolymers; and blowing agents mainly used include hydrocarbons such as isobutane and isopentane (see Patent Document 1). Patent Document 2 discloses thermally expandable microcapsules having high thermal durability, for example, comprising a thermoplastic resin prepared from a component containing 80% by weight or more of a nitrile monomer, 20% by weight or less of a non-nitrile monomer, and a crosslinking agent the shells of those. The method prepares heat-expandable microcapsules in an aqueous dispersion medium...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F2/44B01J13/04

CPCC08F2/20B01J13/14C08F2/44Y10T428/2982Y10T428/2985Y10T428/2987Y10T428/2989B01J13/04

Inventor 内藤大树川南聪三木胜志寄岛郁雄北野健一

Owner MATSUMOTO YUSHI SEIYAKU

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com