Method of producing natural cheese

A natural cheese and cheese technology, applied in the field of natural cheese preparation, can solve the problems affecting cheese milk, different physical properties of curdled milk, poor physical properties and taste of curdled milk, etc., and achieve the effect of improving acid production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0035]

[0036] In this embodiment, the pre-ripening process is simplified in the natural cheese production process. Moreover, in order to simplify the pre-ripening process, a starter with increased acid production activity was prepared.

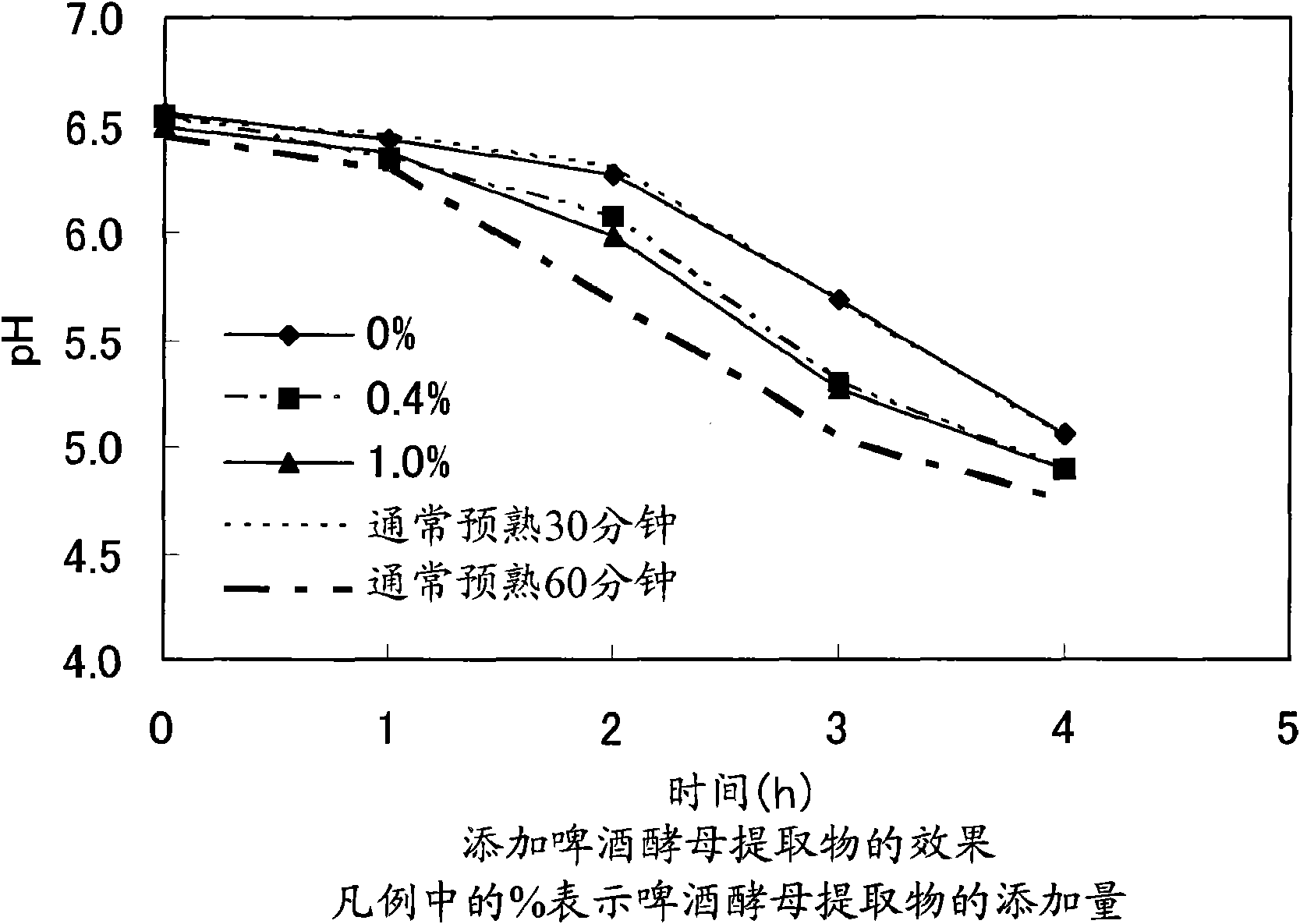

[0037] Next, a method for preparing a starter having enhanced acidogenic activity will be explained. Yeast extract is used as a growth-promoting substance for lactic acid bacteria, and an appropriate amount is added to reconstituted skim milk to generate a culture solution. Then, the lactic acid bacteria are cultured at 35° C. for about 2.5 hours to 3.5 hours using the culture solution, and the culture is terminated in the middle of the logarithmic growth phase to prepare a starter having high acid-producing activity. This starter has a low lactic acid concentration.

[0038] In order to increase the acid-producing activity of the starter, 0.1% by weight or more of the yeast extract may be added to the culture solution. However, in orde...

Embodiment 1

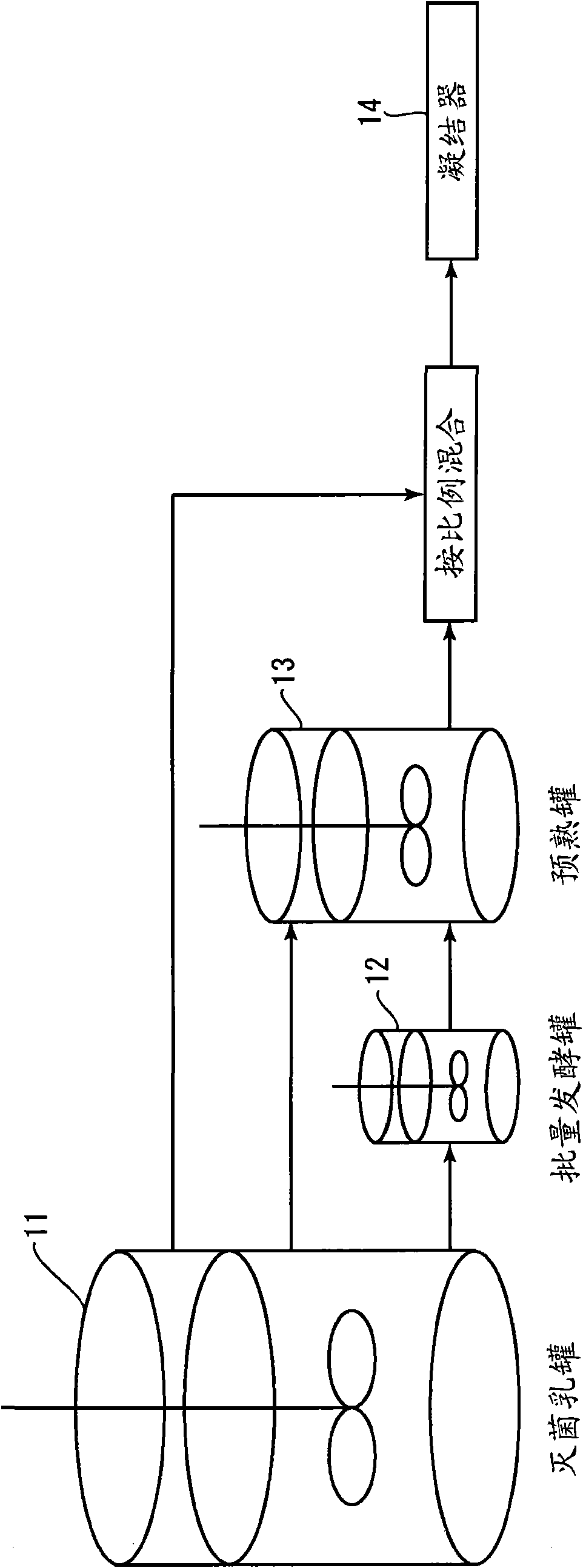

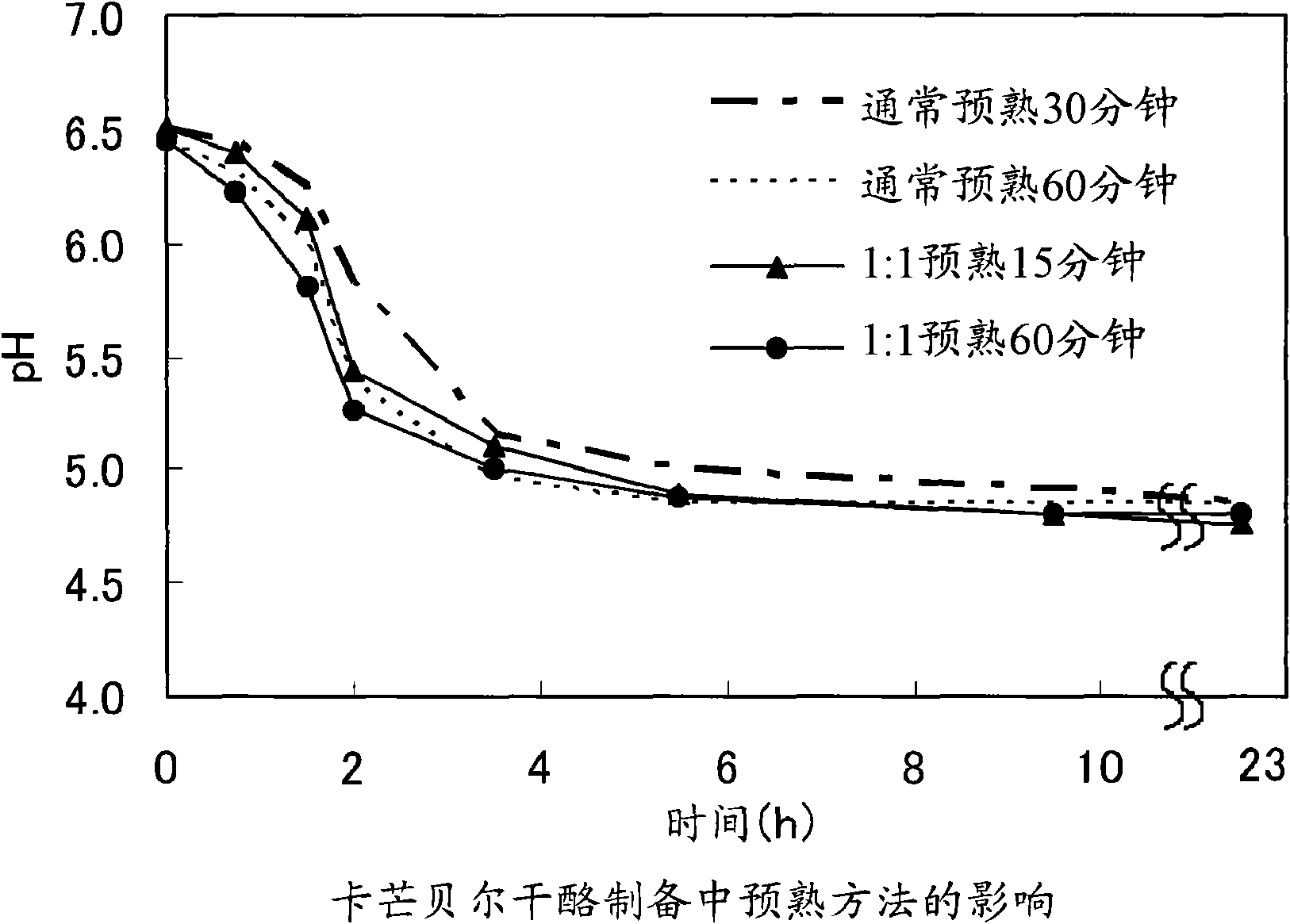

[0045] figure 1 It is a schematic diagram of a production system for continuous production of natural cheese through simplified pre-ripening treatment. In this example, the starter was mixed with cheese milk in a weight ratio of 1:1 for pre-ripening ("1:1 pre-ripening").

[0046] First, the sterilized milk for the batch starter is delivered to the batch fermenter 12 through the sterilized milk tank 11 . As described above, yeast extract is added to sterilized milk in the batch fermenter 12 to produce a culture solution, and a starter is added to the culture solution to perform cultivation. The culture is terminated in the middle of the logarithmic growth phase to prepare a starter having high acid-producing activity.

[0047] Then, all the starter cultures with increased acid production activity are sent to the pre-ripening tank 13 . Furthermore, sterilized milk for pre-ripening is transferred from the sterilized milk tank 11 to the pre-ripening tank 13 . As mentioned abov...

Embodiment approach 2

[0053]

[0054] In this embodiment, the pre-ripening process is omitted in the production process of natural cheese. In order to omit the pre-ripening process, a starter with further improved acid production activity was prepared.

[0055] Hereinafter, a method for preparing a starter with further improved acidogenic activity will be described. 0.2% by weight of the yeast extract was added to the reconstituted skim milk to produce a culture solution. The added concentration of this yeast extract should be set taking into account its negative impact on whey flavor. Use this culture solution to cultivate lactic acid bacteria at 40° C. for about 4.5 hours to 6.5 hours. When the acidity of lactic acid becomes 0.6% to 0.8% (about 0.7%), the culture is terminated to obtain a starter with high acid production activity.

[0056] In actual cheese preparation, the starter prepared by the above method was added to cheese milk at 3% by weight, and the addition of rennet in the pre-rip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com