Method for simultaneously producing glutathione and S-adenosyl methionine at high yield

A technology of adenosylmethionine and glutathione, which is applied in the field of bioengineering and can solve the problem of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

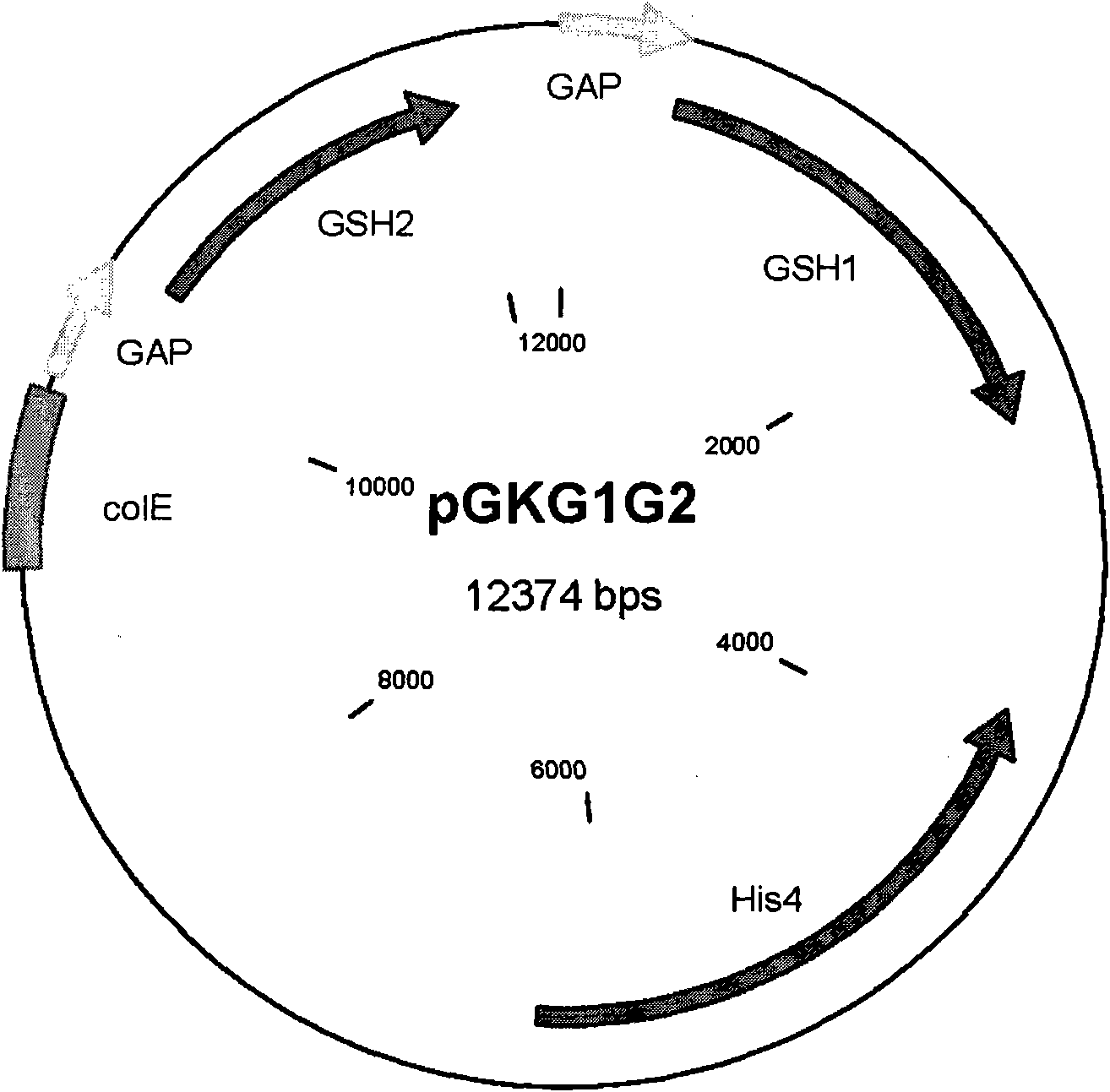

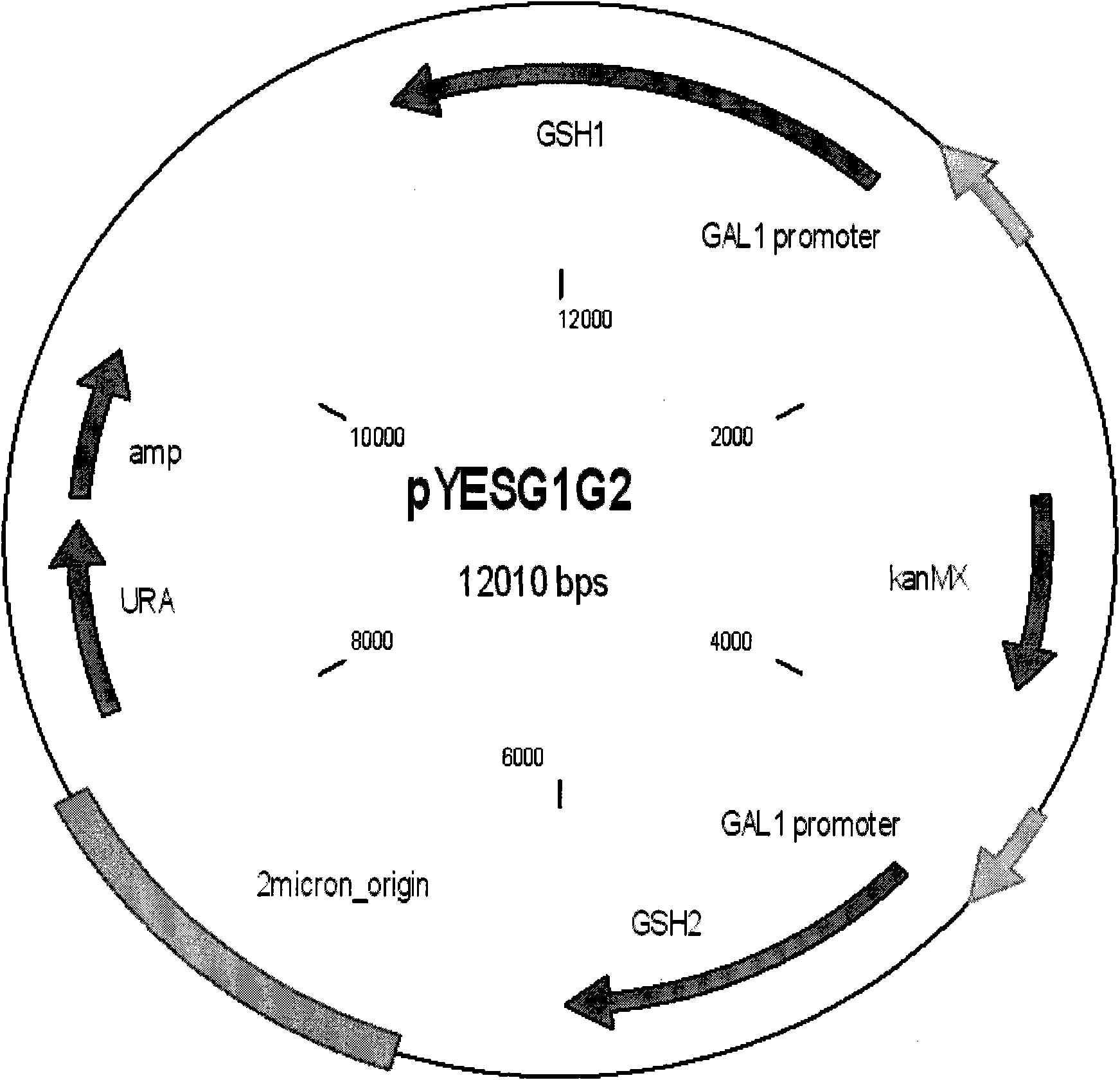

[0043] Example 1 1. Construction of strains co-expressing glutathione synthetase and SAM synthetase

[0044] In this example, plasmids for expressing glutathione synthetase and SAM synthetase for Pichia or Saccharomyces cerevisiae were first constructed, and then the above-mentioned plasmids that had been constructed were transformed into corresponding Pichia Yeast or Saccharomyces cerevisiae, so as to construct strains that can co-express glutathione synthetase and SAM synthetase in Pichia pastoris and Saccharomyces cerevisiae.

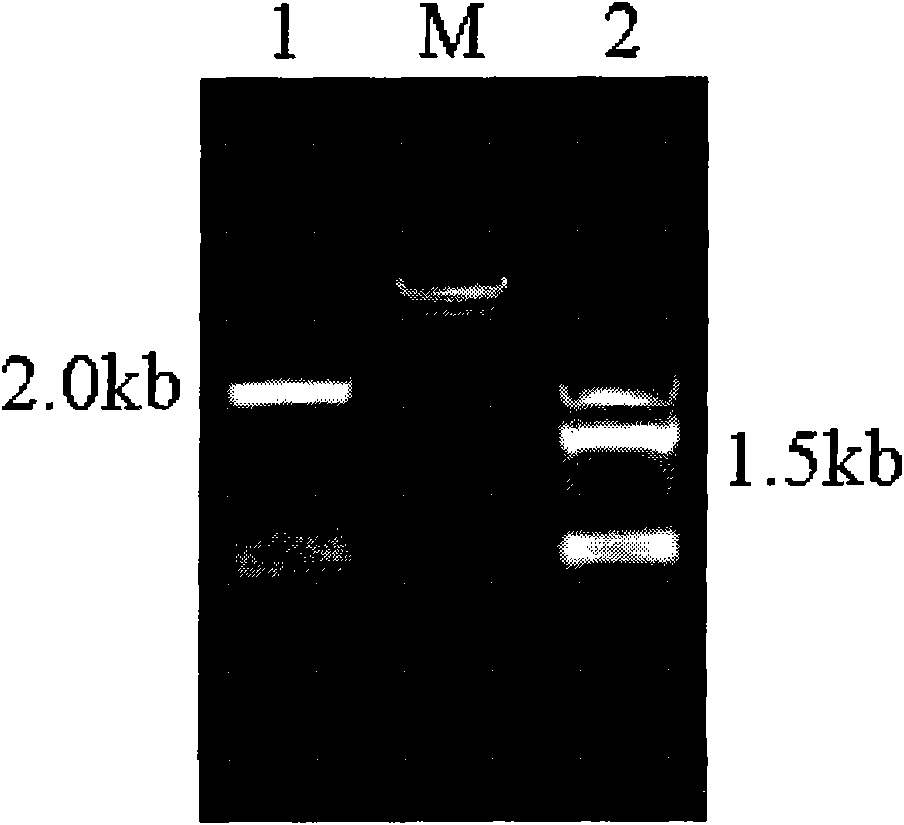

[0045] 1.1, GSH1, GSH2, SAM fragment amplification

[0046] In this example, primers for amplification were first designed, the genome as the amplification template was extracted, and then the fragments of GSH1, GSH2 and SAM synthetase 2 were respectively amplified by PCR, as follows:

[0047] According to the GSH1 and GSH2 sequences reported by Genebank (EF633694, EF633695), the following 4 primers were designed for cloning the GSH1 and GSH2 sequ...

Embodiment 2

[0138] Example 2 , HZ111 fermentation to produce glutathione and S-adenosylmethionine simultaneously or separately

[0139] Select a single colony of HZ111 that has grown for three days and inoculate it into 30ml of YPD medium, culture it at 30°C and 240rpm for 20h, then insert it into 320ml of YPD medium, cultivate it at 30°C and 240rpm for about 8h, and insert it into 3.15L of fermentation medium BMGY (7.5L fermenter), add a final concentration of 0.01% defoamer (polyoxypropylene polyoxyethylene glyceryl ether, i.e. foam enemy), and ferment, the temperature is controlled at 30 ° C, and glycerin is added during the fermentation process to meet the needs of cell growth Need, by adding ammonia water, the pH is controlled at 6.0. Adding a total amount of 30 grams of L-cysteine and a total amount of 30 grams of L-methionine to 30 hours of fermentation continued to ferment, and the fermentation was carried out at 70 hours. The test results showed that glutathione in the fermen...

Embodiment 3

[0141] Example 3 , HZ203 fermentation to produce glutathione and S-adenosylmethionine simultaneously or separately

[0142] The formula of the medium used in the present embodiment is as follows (g / L):

[0143] Galactose 40, yeast extract 20, peptone 40, ammonium sulfate 2.0, urea 2.0, KH 2 PO 4 1.5, MgSO 4 ·7H 2 O0.5, ZnSO 4 ·7H 2 O 4.0×10 -3 , FeSO 4 ·7H 2 O 3.0×10 -3 , MnCl 2 4H 2 O 0.3×10 -3 , CuSO 4 ·5H 2 O0.5×10 -3 , CaCl 2 2H 2 O 1.0×10 -3 .

[0144] Pick a single colony of HZ203 that has grown for two days and inoculate it into 30ml of the above-mentioned medium, culture at 30°C and 240rpm for 20h, then insert 320ml of the above-mentioned medium, cultivate at 30°C and 240rpm for about 6h, and insert 3.15L of the above-mentioned fermentation culture In the base (7.5L fermenter), add 0.01% final concentration of antifoaming agent foam enemy, carry out fermentation, the temperature is controlled at 30 ℃, add galactose during the fermentation process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com