Compound pot bottom of aluminum pot and manufacturing method thereof

A manufacturing method and technology for aluminum pots, applied in the field of tableware pots, can solve the problems of complex processing technology, thick steel plate thickness, prolonged heating time, etc., and achieve the effects of simple production process, good heat conduction effect, and low equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The detailed description and technical content of the present invention are described below with the drawings, but the drawings are only for reference and illustration, and are not intended to limit the present invention.

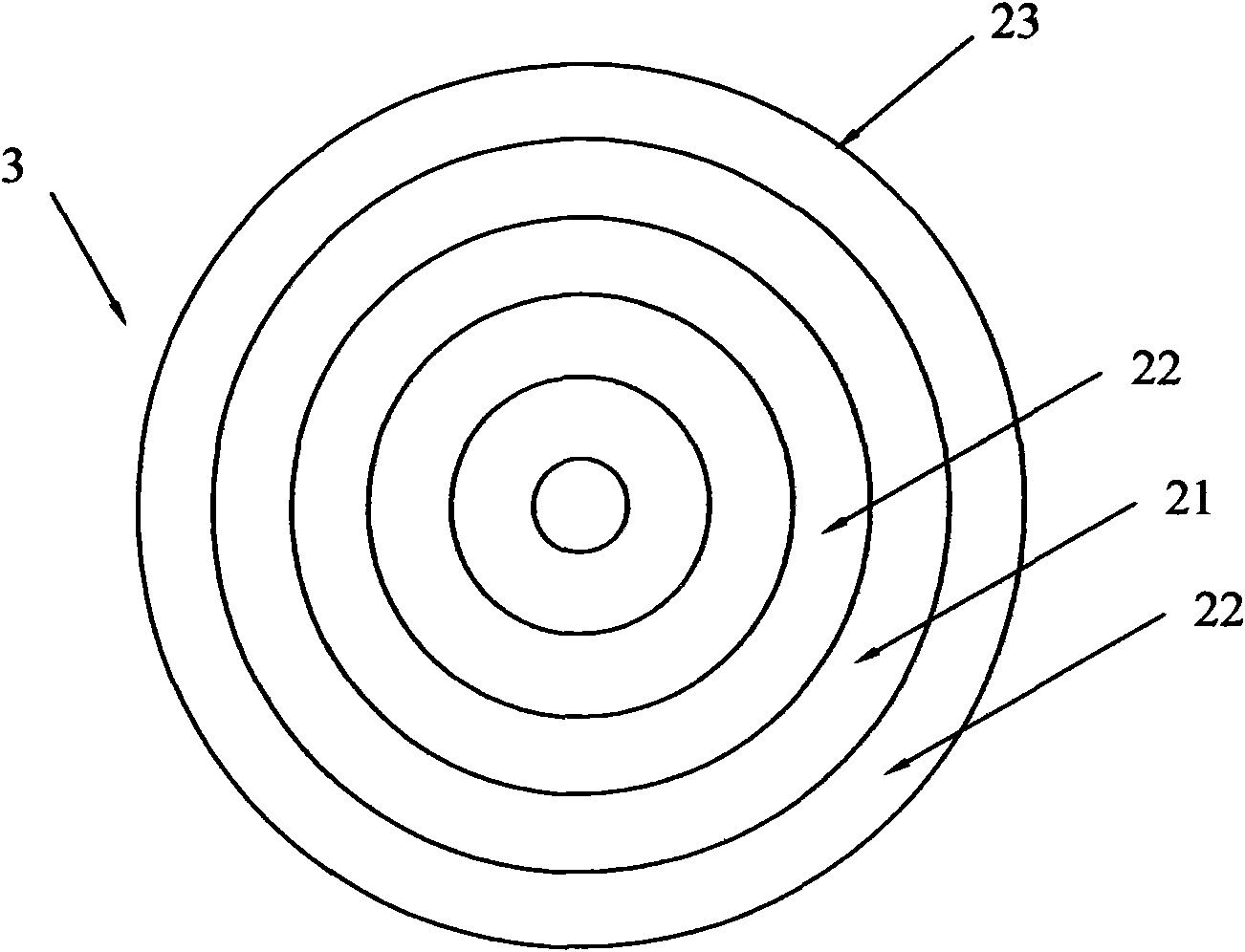

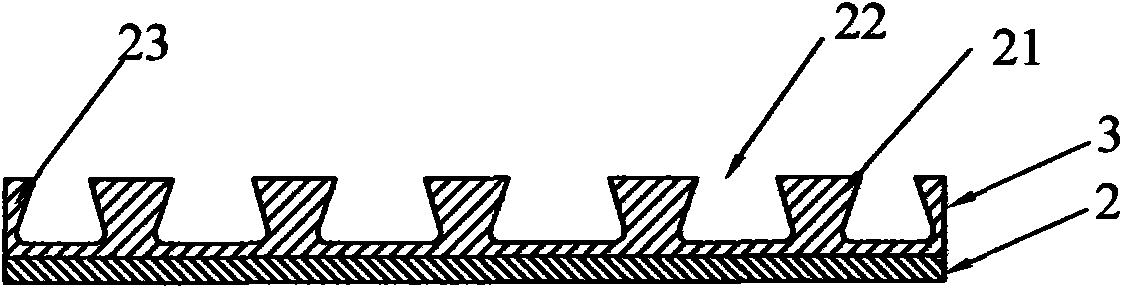

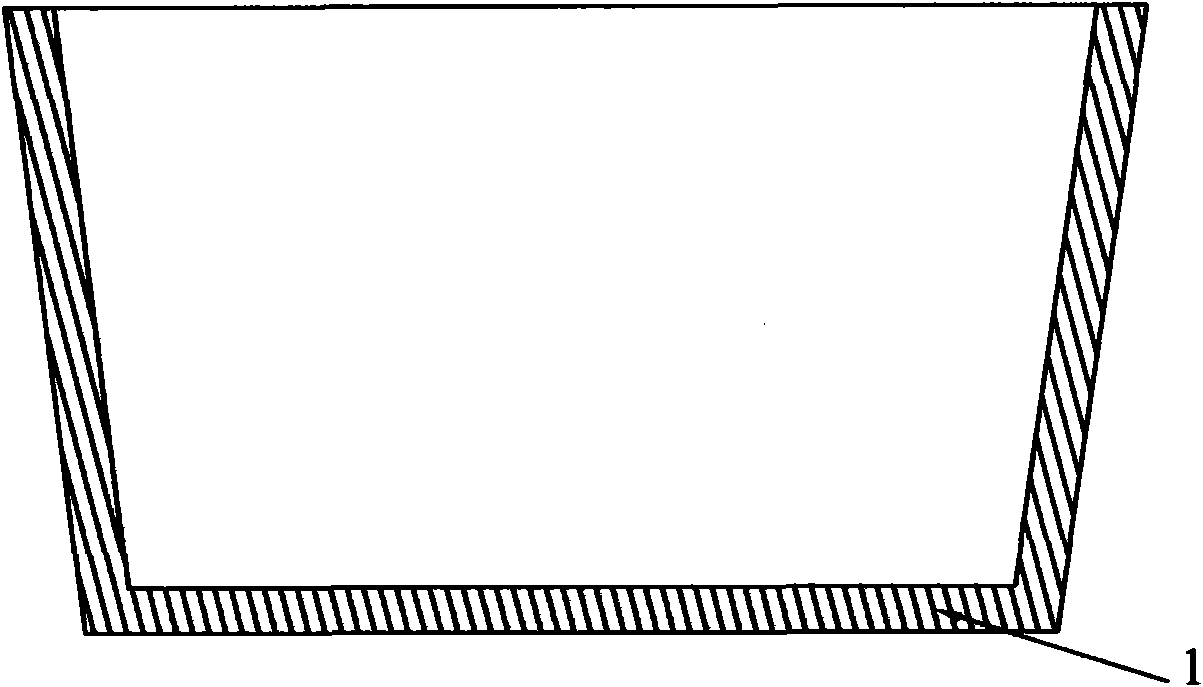

[0028] see Figure 1 to Figure 4 As shown, the present invention provides a composite pot bottom of an aluminum pot, which is compounded with a magnetically conductive metal plate 2 on the bottom surface of the aluminum pot bottom 1, and the magnetically conductive metal plate 2 adopts a shape adapted to the aluminum pot bottom. Its material can be stainless iron or other magnetically conductive metal materials. Wherein, the surface of the magnetically conductive metal plate 2 and the aluminum pan bottom is combined with an aluminum plate 3 under high temperature and high pressure, and the upper surface of the aluminum plate 3 is provided with a plurality of concentric ring-shaped protrusions 21 at intervals with the center as the center of the circl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com