Production test system of large-scale short-distance wireless data transmission equipment

A short-distance wireless and data transmission technology, applied in the transmission system, transmission monitoring, electrical components, etc., can solve the problems of labor cost extension, increased production cost, cumbersome test process, etc., to reduce labor costs, reduce time and cost costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

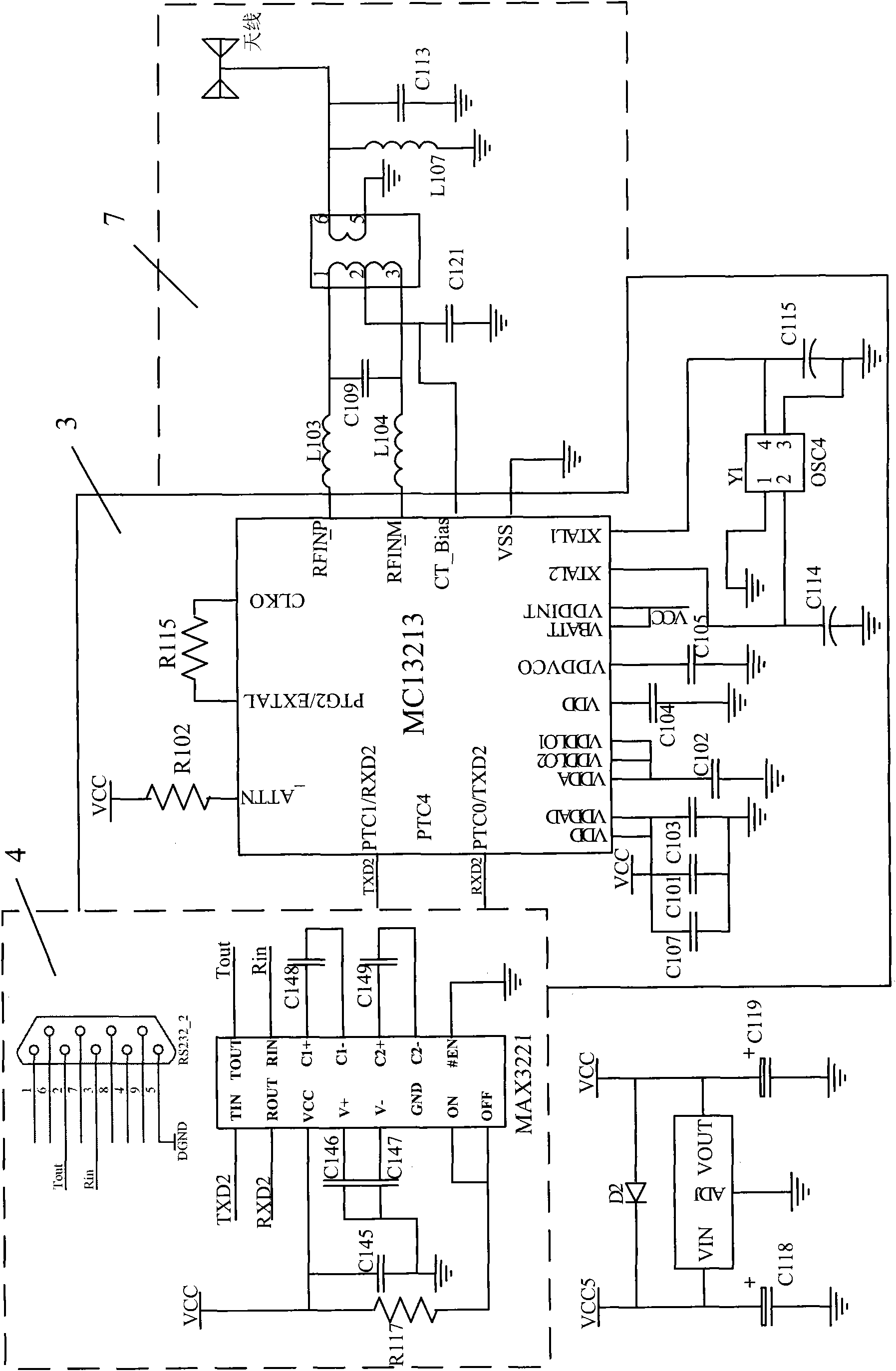

[0034] Embodiment 1: as figure 1 As shown, the production test system of the short-distance wireless data transmission device of this embodiment includes a radio frequency performance testing device 1 and at least one short-distance wireless data transmission device 2 to be tested, and the radio frequency performance testing device 1 includes a microprocessor The radio frequency unit 3 is connected with the RS232 serial port communication unit 4 and the matching radio frequency transceiver circuit 7 .

[0035] The short-distance wireless data transmission device 2 to be tested includes a microprocessor radio frequency module 6 and a matching radio frequency transceiver module 8 connected thereto. The microprocessor radio frequency module 6 receives and sends radio frequency signals through the matching radio frequency transceiver module 8 .

[0036] Such as figure 2 As shown, the radio frequency performance testing device 1 of this embodiment uses Freescale's MC13213 as the ...

Embodiment 2

[0062] Embodiment 2: In this embodiment, the microprocessor radio frequency unit 3 includes an independent microprocessor and a 2.4GHz radio frequency transceiver unit connected to each other. The interface signals between the microprocessor and the wireless radio frequency transceiver unit include: the control signal sent by the microprocessor to the wireless transceiver unit, the data signal of the microprocessor and the wireless transceiver unit, wherein the control signal sent by the microprocessor includes the control signal of the wireless transceiver unit Signals working in the transmitting or receiving state, the first data output port of the microprocessor is connected to the first data input port of the wireless transceiver unit, and the second data output port of the wireless transceiver unit is connected to the first data input port of the microprocessor. The wireless radio frequency transceiver unit performs digital spread spectrum and radio frequency modulation on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com