Method for manufacturing lithium-ion batteries

A technology of lithium-ion batteries and manufacturing methods, which is applied in the field of battery manufacturing, can solve problems such as reduced utilization of active materials, inability to use high-current pre-charging, and affecting battery safety performance, so as to improve capacity, shorten pre-charging time, and eliminate Or reduce the effect of lithium analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

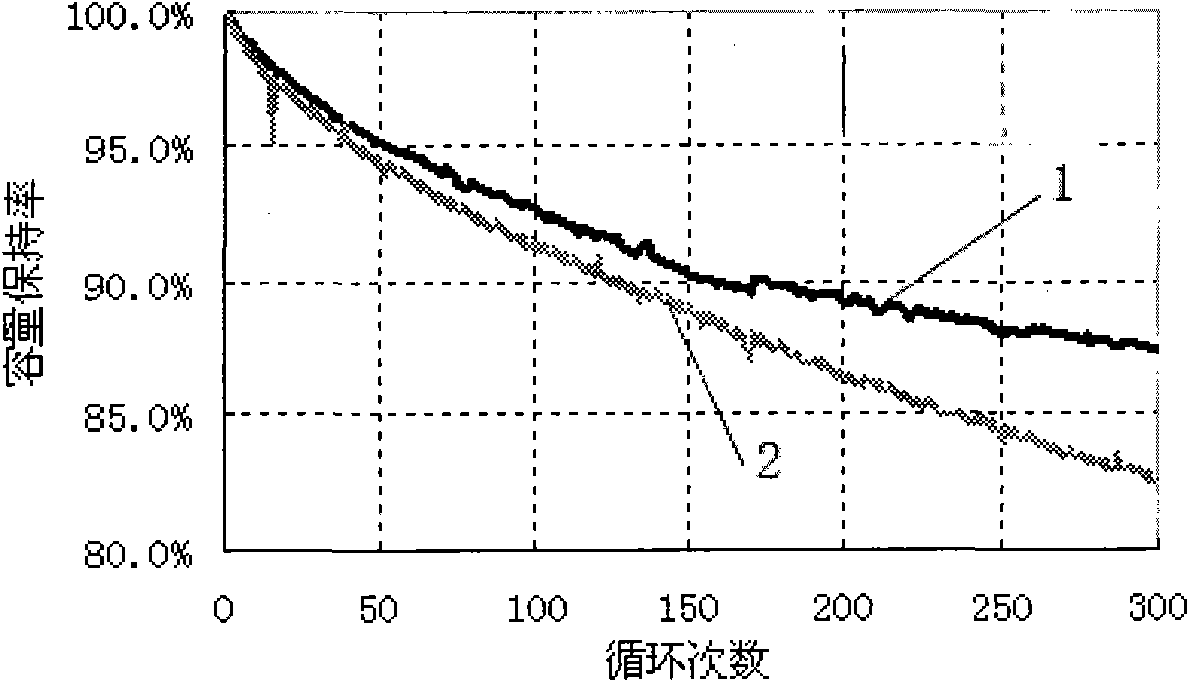

[0023] Assemble a set of 423450A batteries from Shenzhen BAK Battery Co., Ltd. Thickness × width × height = 4.5mm × 34mm × 50mm. The positive electrode material is lithium cobalt oxide. Charge at 0.5C constant current for 30 minutes, the entire pre-charge time is 60 minutes, and the pre-charge capacity is 30% of the nominal capacity. During the whole pre-charging process, the pipeline pumping pressure of the vacuum device is constant at 0.07MPa. After testing, the specific capacity of lithium cobalt oxide is 147.8mAh / g at 0.2C constant current discharge and 146.1mAh / g at 1C constant current discharge for the battery using the above precharging method. After 300 cycles, the capacity retention reached 87.4%.

[0024] Use the conventional method for the above-mentioned other batteries in the same group, that is, do not evacuate during pre-charging, and pre-charge at 0.1C for 390 minutes. After testing, the specific capacity of lithium cobaltate is only 146.3mAh / g at 0.2C consta...

Embodiment 2

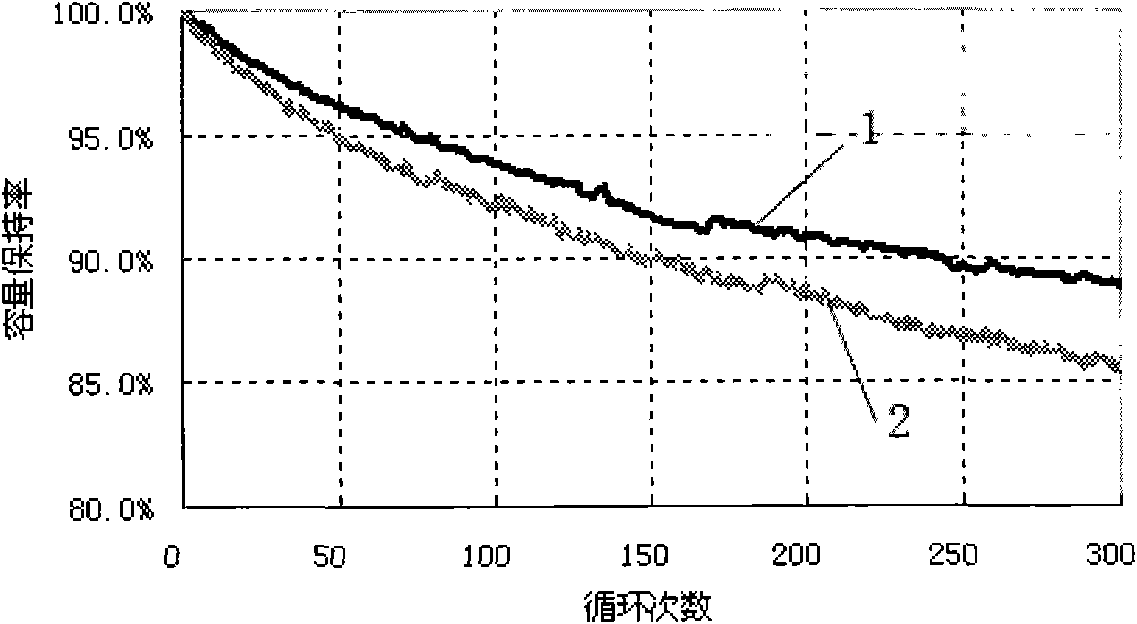

[0027] Assemble a set of batteries of Shenzhen BAK Battery Co., Ltd. model 423048A, thickness × width × height = 4.5mm × 30mm × 48mm, the positive electrode material of the battery is a mixed system of lithium cobalt oxide and lithium nickel cobalt manganese oxide, first with 0.1C Constant current charging for 60 minutes, then 0.3C constant current charging for 30 minutes, and then 0.5C current pre-charging for 12 minutes, the entire pre-charging time is 102 minutes, and the pre-charging capacity is 35% of the nominal capacity. During the first 90 minutes of pre-charging, the pipeline pumping pressure is constant at 0.05 MPa, and during the last 12 minutes of pre-charging, the pumping pressure is constant at 0.08 MPa. After testing, the specific capacity of the positive electrode active material is 150.6mAh / g at 0.2C constant current discharge and 146.3mAh / g at 1C constant current discharge for the battery using the above precharging method. After 300 cycles at 1C, the capacit...

Embodiment 3

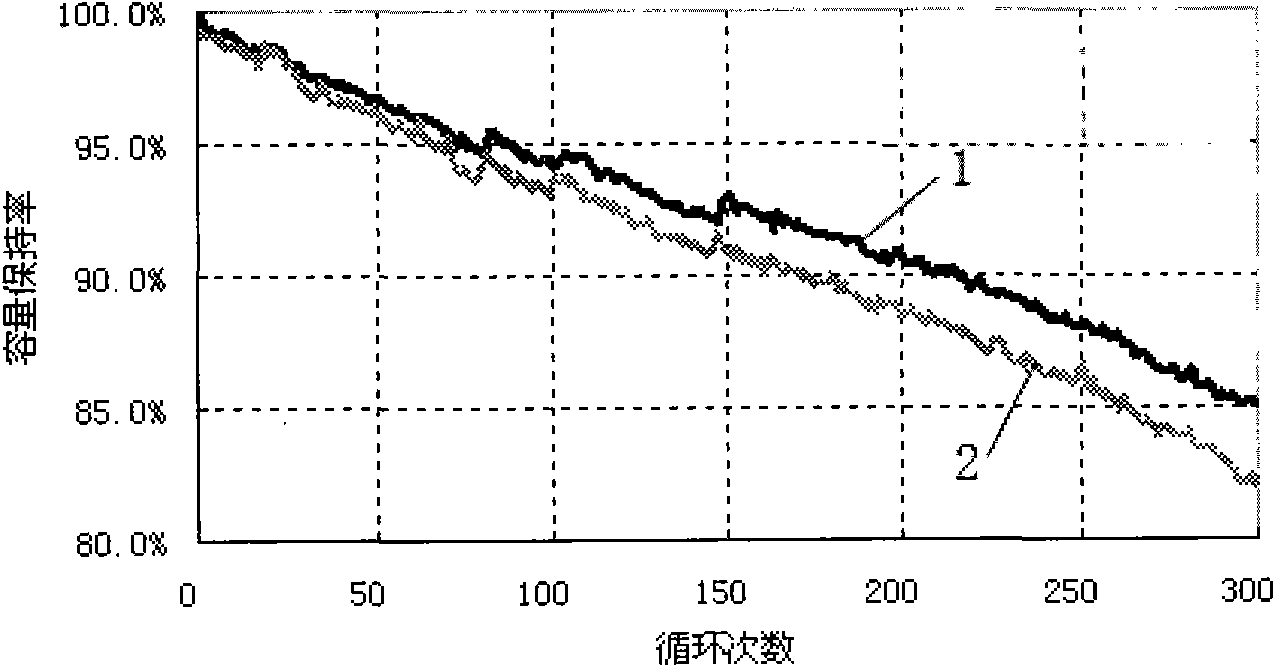

[0031] Assemble a set of batteries of Shenzhen BAK Battery Co., Ltd. model 053048A, thickness × width × height = 5.3mm × 30mm × 48mm, the positive electrode material of the battery is a mixed system of lithium manganese oxide and nickel cobalt lithium manganese oxide, first with 0.1C Constant current charging for 30 minutes, then 0.3C constant current charging for 30 minutes, then 0.6C current pre-charging for 30 minutes, the entire pre-charging time is 90 minutes, and the pre-charging capacity is 50% of the nominal capacity. During the first 70 minutes of pre-charging, the pipeline pumping pressure is constant at 0.05MPa, and during the last 20 minutes of pre-charging, the pumping pressure is constant at 0.08 MPa. After testing, the specific capacity of the positive electrode active material is 129.8mAh / g at 0.2C constant current discharge and 126.9mAh / g at 1C constant current discharge for the battery using the above precharging method. After 300 cycles at 1C, the capacity r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com