Fire-resistant cable for bus and silicon rubber mixture of cable extrusion silicon rubber layer

A technology of fire-resistant cable and fire-resistant layer, applied in the direction of insulated cable, rubber insulator, cable, etc., to achieve low dielectric constant, reduce attenuation, and satisfy the effect of dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

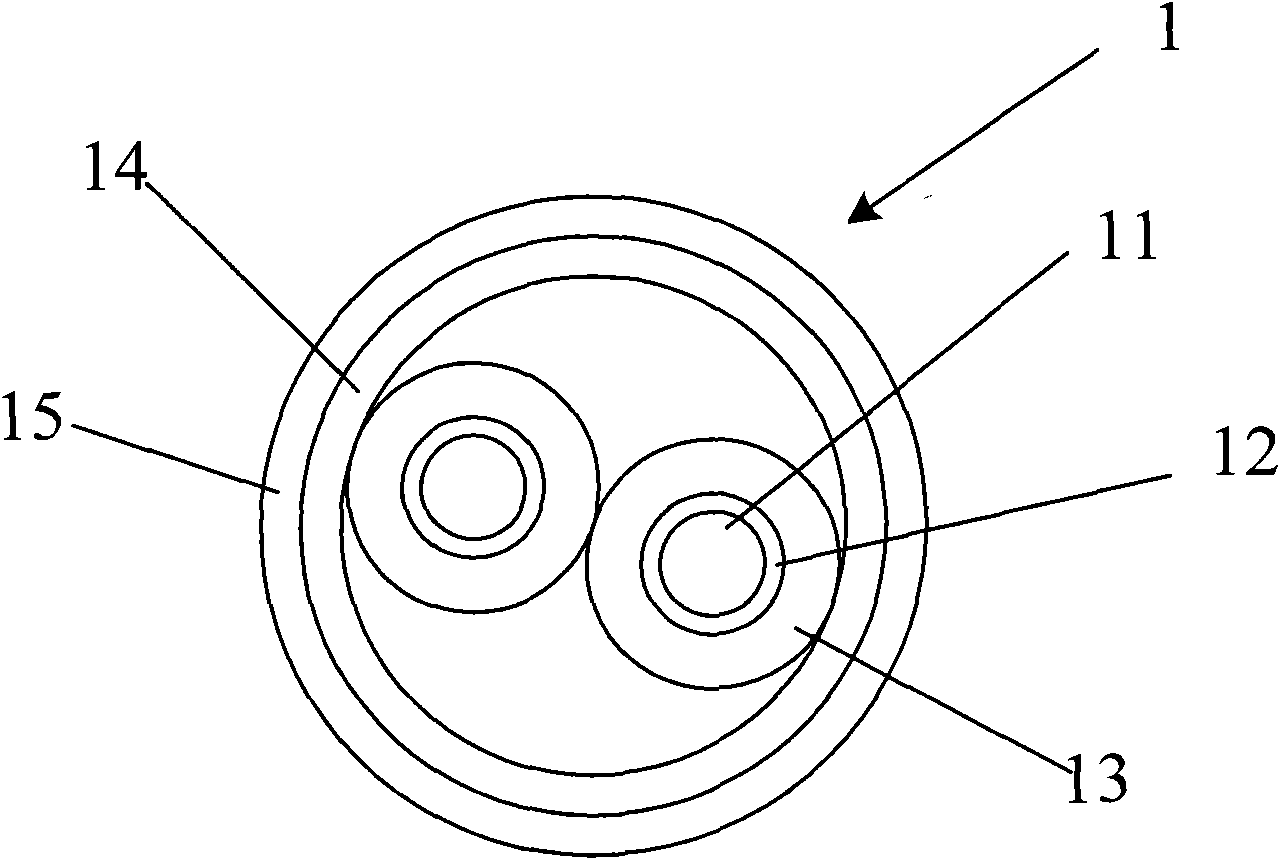

[0023] figure 1 It is a structural schematic diagram of the fire-resistant cable for the bus of the present invention. Wherein, the fire-resistant layer of the fire-resistant cable for the bus is made by extruding the silicone rubber mixture in the present invention. Cable 1 adopts copper stranded wire 11, and extruded silicone rubber mixture refractory layer 12 with a thickness of 0.10-0.15 mm is extruded on copper stranded wire 11. In particular, the extruded silicone rubber mixture refractory layer 12 in the present invention requires Made of silicone rubber with low dielectric constant. A polyethylene insulating layer 13 with a thickness of 0.35 mm is wrapped around the extruded silicone rubber mixture refractory layer 12, and foamed polyethylene or foamed cross-linked polyethylene can also be used as a substitute to compensate for the disadvantages caused by the use of silicone rubber. The problem of increasing the effective dielectric constant. The metal shielding 14 ...

Embodiment 2

[0025] Compared with embodiment 1, the difference between this embodiment and embodiment 1 is that figure 1 The extruded thickness of the extruded silicone rubber mixture refractory layer 12 is 0.15-0.20mm. Wherein, when the highest transmission frequency is 10MHz, the extruded thickness of the extruded silicone rubber mixture refractory layer may be 0.15mm-0.20mm. All the other parts are identical to Example 1.

[0026] Wherein, the extruded silicone rubber mixture refractory layer in Examples 1 and 2 adopts commercially available ELASTOSIL-N2010 single-component room temperature vulcanized silicone rubber (produced by Wacker Company of Germany) and L-41 silicone oil (produced by Dow Corning Company of the United States) according to its The volume ratio is 9:1, mixed and then extruded, and its dielectric constant is 2.4-3.5 under the measurement condition below 1MHz.

Embodiment 3

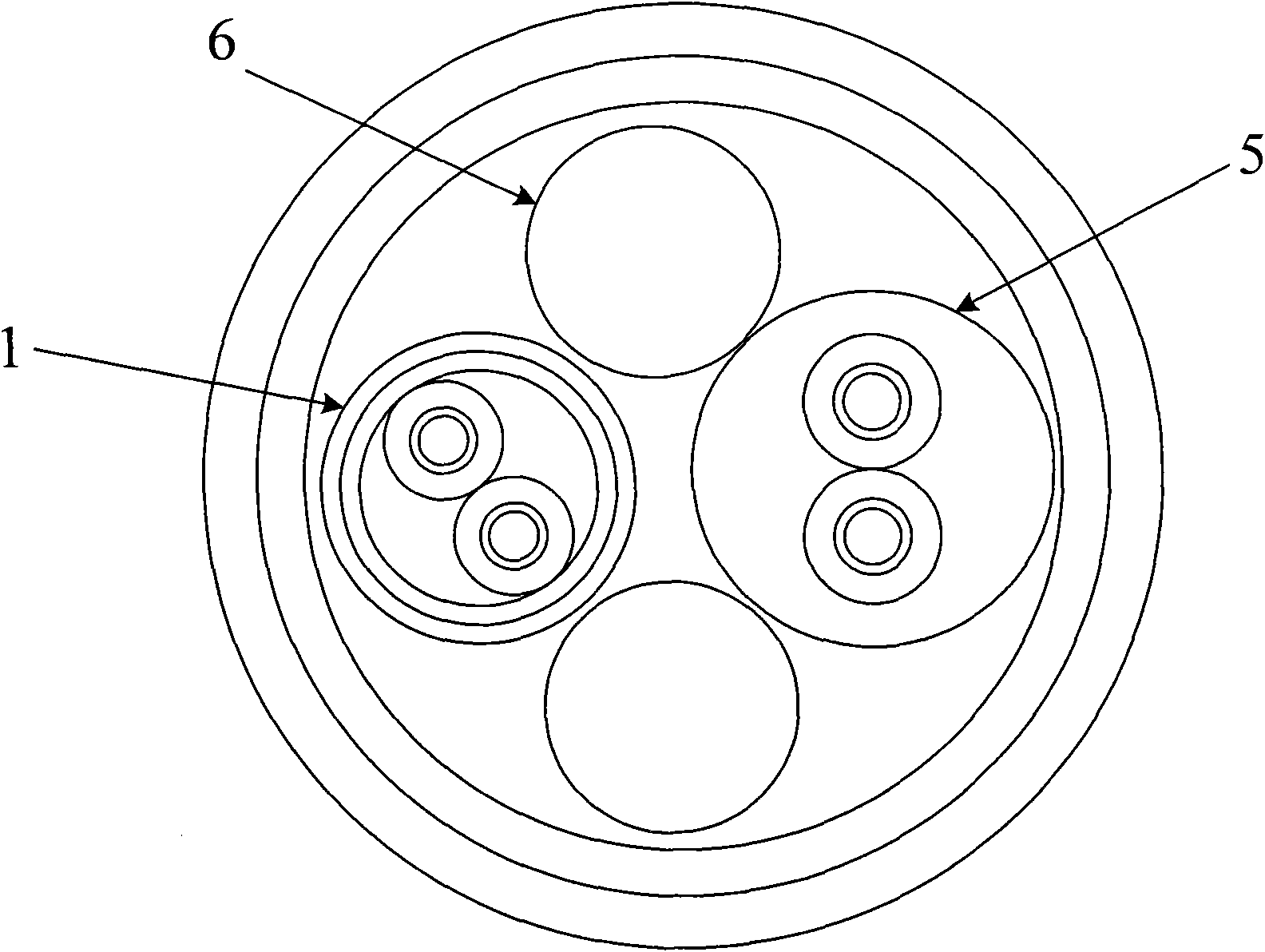

[0028] figure 2 In order to apply the present invention to an embodiment of a fire-resistant cable for a Can bus, this embodiment uses the cable 1 in Embodiment 1 as a signal transmission line pair. The fire-resistant cable for the Can bus also includes a power cable pair 5 and two filling cores 6. After the four cores are twisted, a metal overall shield is braided on the outer layer and a total sheath is provided on the metal overall shielding jacket.

[0029] In the present embodiment, the extruded silicone rubber mixture refractory layer with a thickness of 0.10-0.15mm can not only ensure the transmission characteristics of the Can bus cable with double-layer insulating medium, such as guaranteeing the characteristic impedance (120Ω) at 10MHz-100MHz, which is relatively Small attenuation, crosstalk, and structural return loss; and its fire resistance can pass the IEC60331.1 regulation to maintain the line integrity test, the fire supply temperature is 750 ℃, and the two in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com