Device and method for detecting characteristics of pulse type semiconductor laser

A detection device and detection method technology, applied in the direction of single semiconductor device testing, etc., can solve the problems of water vapor and other problems, achieve the effect of long heat dissipation time, improve accuracy, and reduce heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

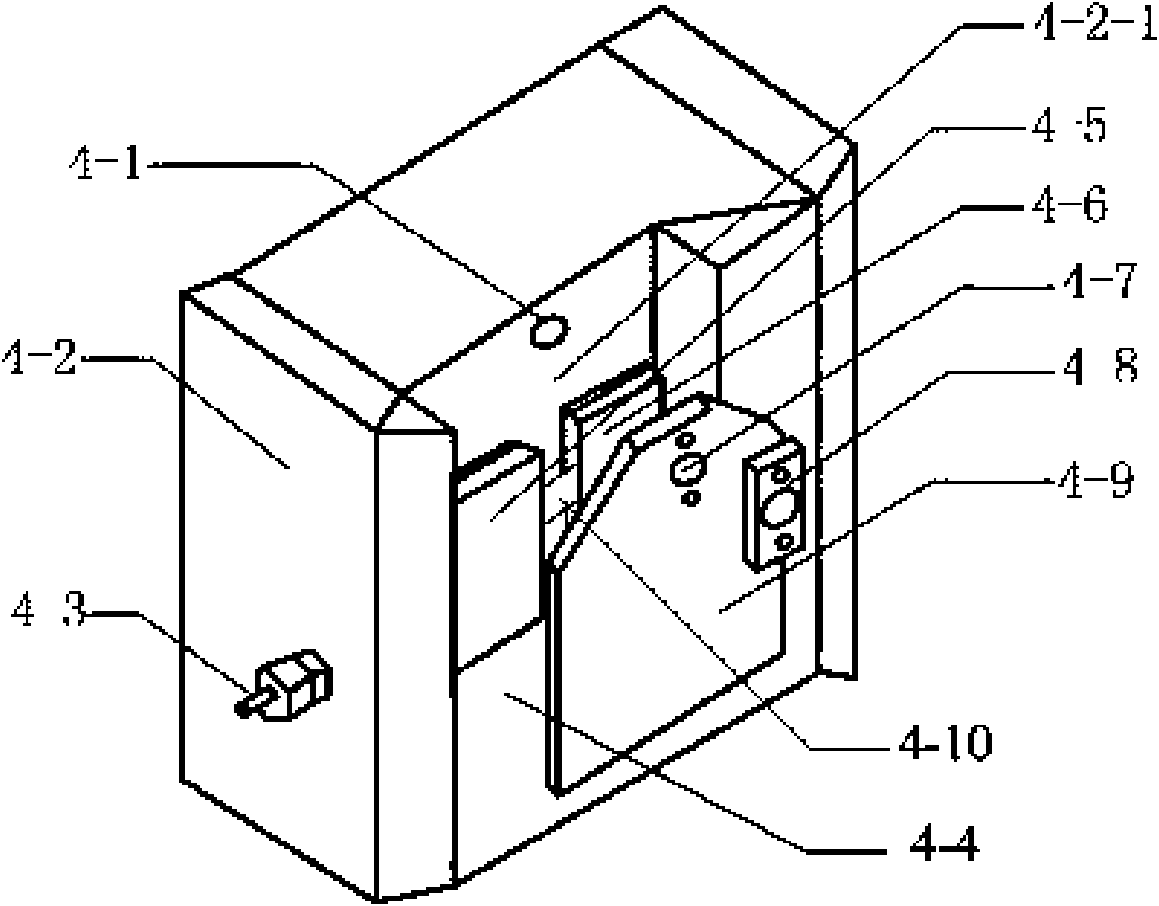

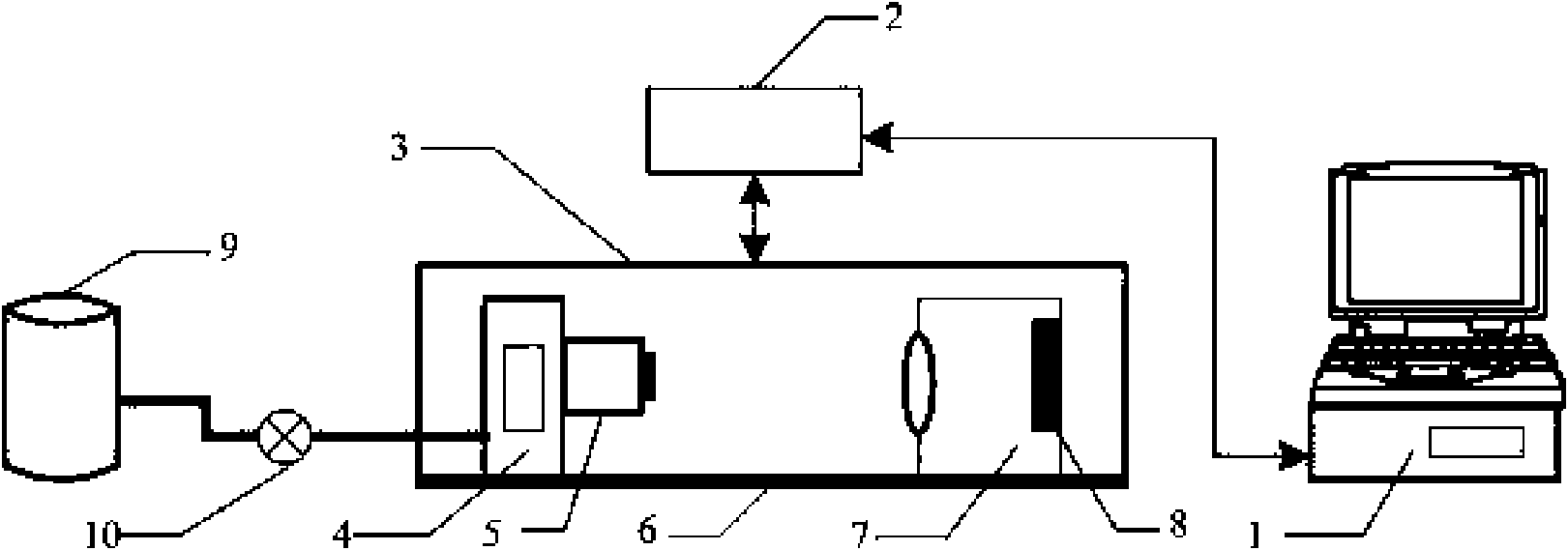

[0016] A pulsed semiconductor laser characteristic detection device described in this embodiment is composed of a computer 1, a hardware control circuit 2, a shield 3, a laser fixture 4, a base 6 and a light output detection device 7, and the shield 3 is placed on the base On the seat 6, and form a closed space with the base 6, the hardware control circuit 2 and the computer 1 are located outside the closed space, the laser fixture 4 and the light output detection device 7 are located inside the closed space, and the laser fixture 4 and the light output detection device 7 Placed on the base 6, the detection window of the light output detection device 7 faces the laser fixture 4, and the central axis of the detection window of the light output detection device 7 is in line with the output of the measured laser installed on the laser fixture 4 The beam centerlines of the laser beams coincide, and the photoelectric signal output end of the light output detection device 7 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com