Connection tube of steel wire mesh framework composite tube and manufacturing method thereof

A technology for connecting pipe fittings and manufacturing methods, applied in the direction of pipes/pipe joints/pipe fittings, pipe connection layout, mechanical equipment, etc., can solve the problems of insufficient connection, low efficiency, high installation technical requirements, etc., and achieve good dimensional stability and interface High strength, safe and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

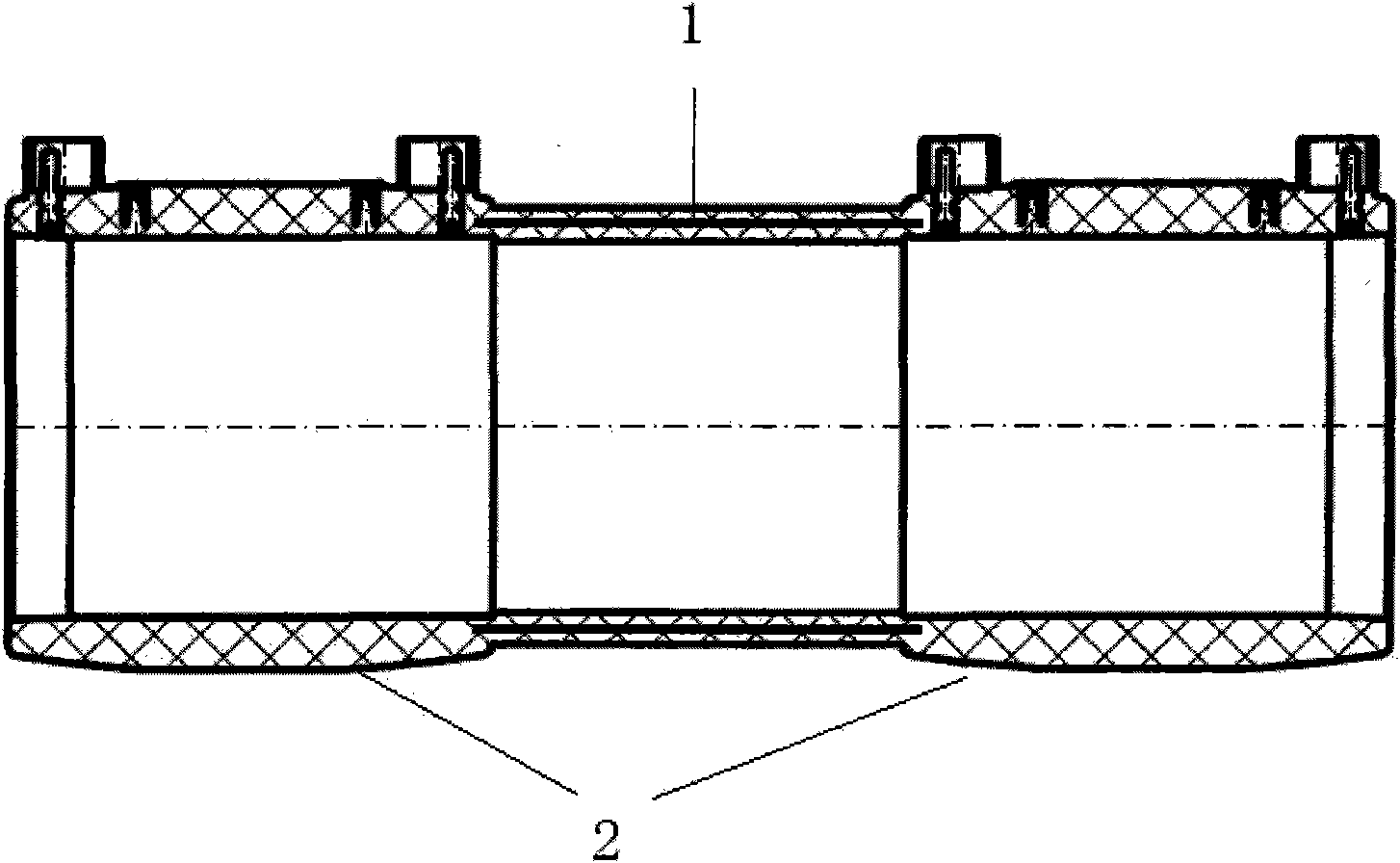

[0016] Such as figure 1 As shown, a piece of pipe with the same specification and material as the steel mesh composite pipe to be connected is used, and the electrofusion pipe fittings 2 are prefabricated at both ends of the pipe through the secondary injection molding process, so as to realize the straight-through joint after the pipe and the electrofusion are integrally formed. The main body of the straight-through joint is a steel mesh skeleton composite pipe main body 1 . The manufacturing method is as follows: a connecting pipe fitting (straight-through) of the steel wire mesh skeleton composite pipe, the main body is the steel wire mesh skeleton composite pipe, and the two ends of the pipe are electrically fused by injection molding technology. When in use, directly connect the pipes to be connected with the connecting pipe fittings, and then weld them by electrofusion.

Embodiment 2

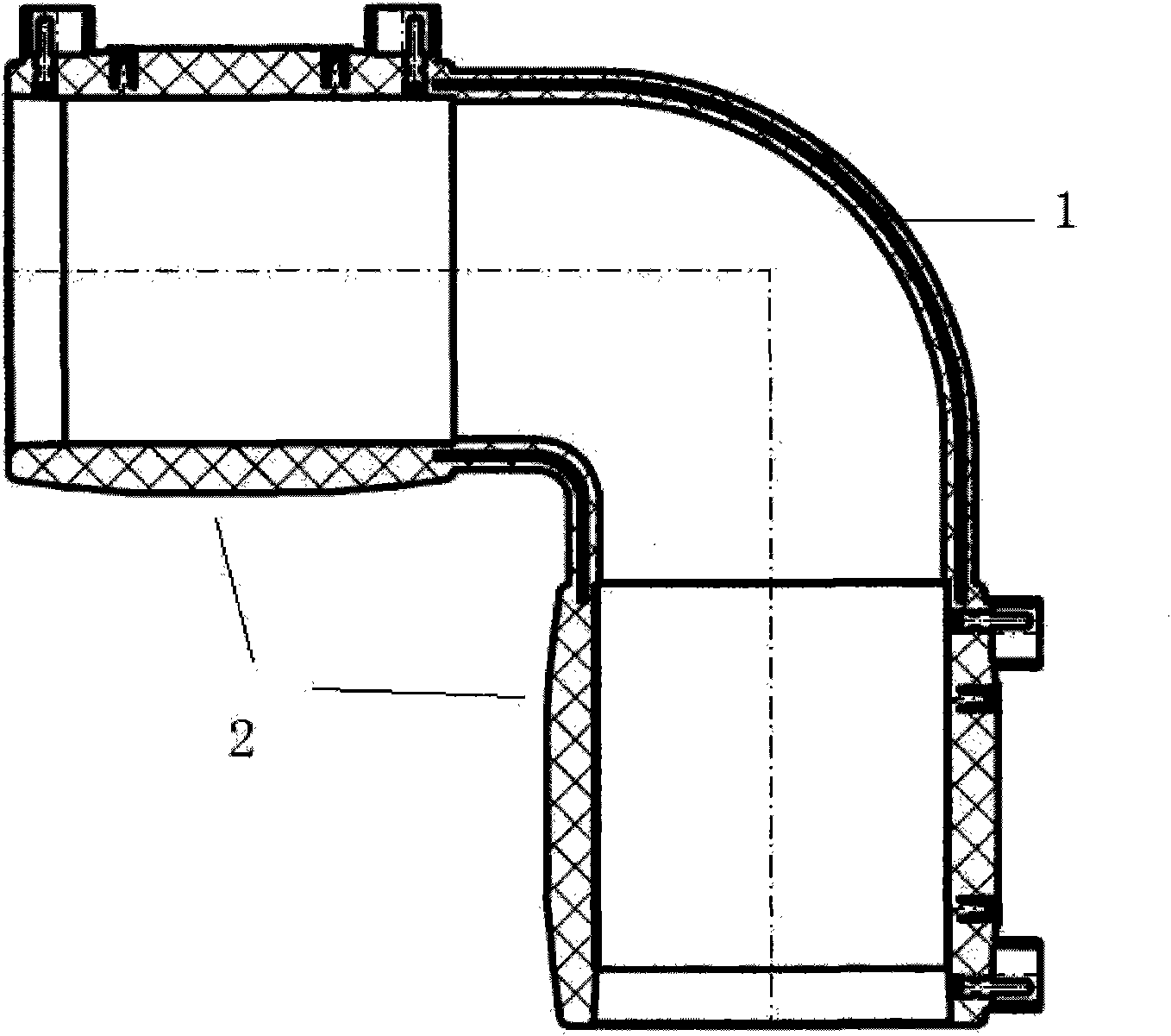

[0018] Such as figure 2 As shown, the steel mesh skeleton composite pipe production process is adopted, and the steel mesh skeleton composite pipe 1 elbow (45°, 90° bend) is processed through a specially made mold; and then through the secondary injection molding process, at both ends of the elbow The electrofusion pipe fittings 2 are prefabricated respectively to realize the steel mesh skeleton composite pipe connection elbow after the elbow and the electrofusion pipe fitting 2 are integrally formed. The connecting pipe fittings (elbows) of the steel wire mesh skeleton composite pipe, the main body is the steel wire mesh skeleton composite pipe, and the two ends of it are electrofused by injection molding technology. When in use, directly connect the pipes to be connected with the connecting pipe fittings (elbows) and perform electrofusion welding.

Embodiment 3

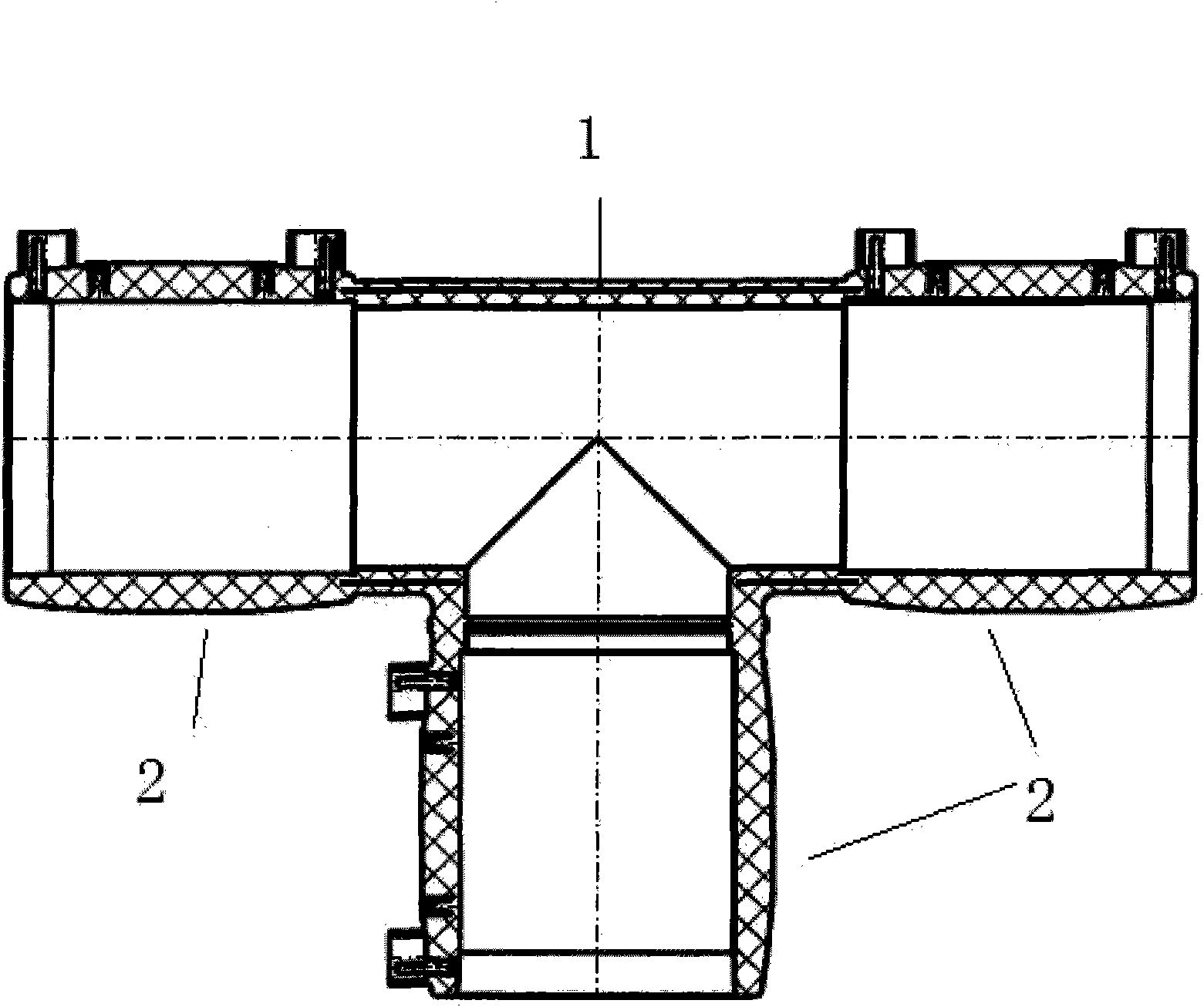

[0020] Such as image 3 As shown, the technology of producing steel mesh skeleton composite pipes is adopted, and the tee connectors are processed through specially made molds; and then the electrofusion pipe fittings 2 are prefabricated at the connector ports through the secondary injection molding process to realize the tee and electrofusion pipe fittings. 2 The integrally formed steel wire mesh skeleton composite pipe is connected to the pipe fitting (tee). The connecting pipe fitting (tee) of the steel mesh skeleton composite pipe, the main body is the steel mesh skeleton composite pipe, which is electrofused to each port by injection molding technology. When in use, directly connect the pipes to be connected with the connecting pipe fittings (tees), and then weld them by electrofusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com