Epoxy resin composition used for shielding deep well submersible pump and casting method thereof

A deep-well submersible pump and epoxy resin technology, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids, can solve the problem that epoxy resin does not meet market demand, human health hazards, and use costs. Advanced problems, to achieve the effects of excellent mechanical properties, improved adhesion strength, and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

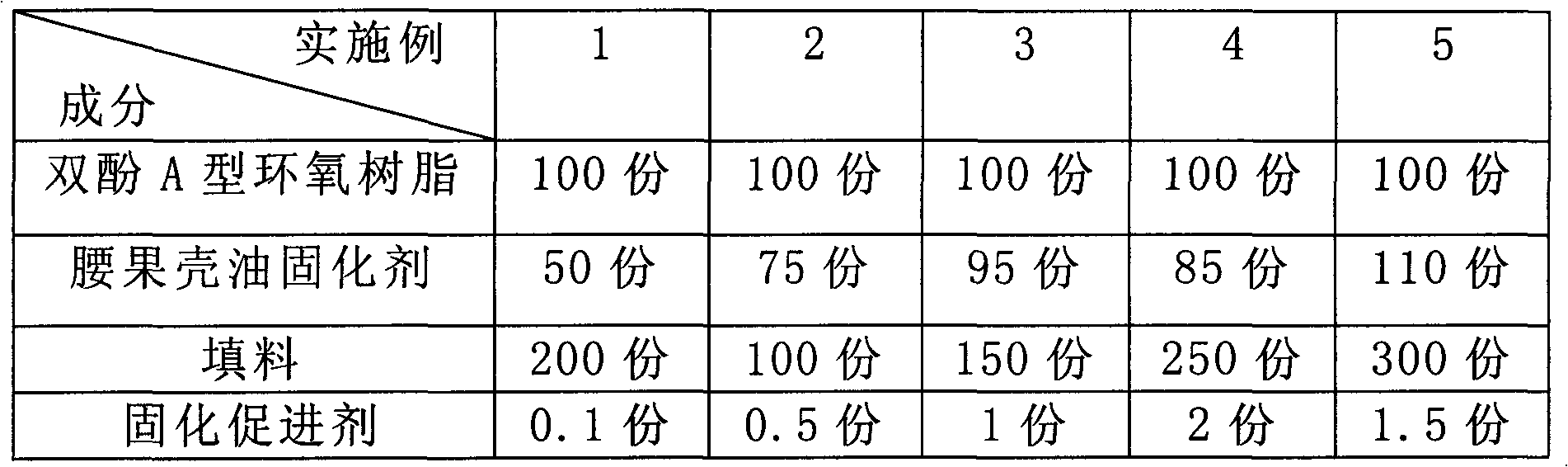

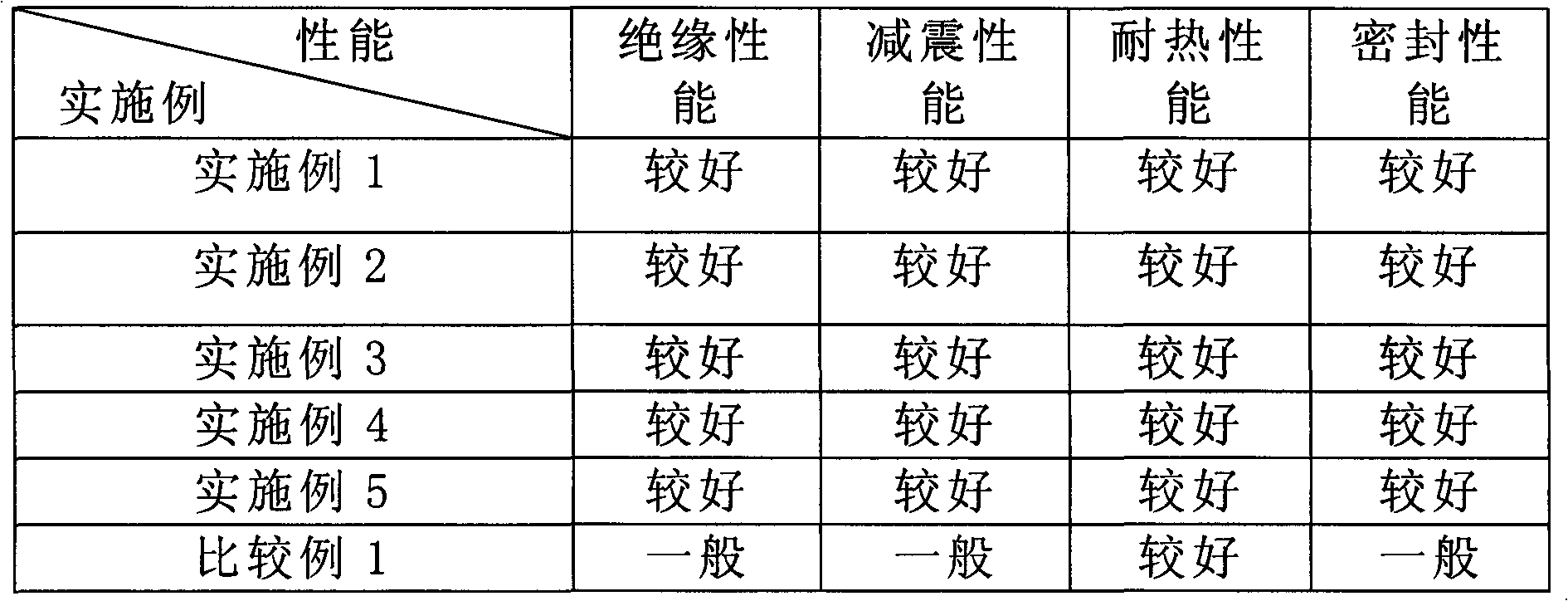

Examples

Embodiment 2

[0036] The bisphenol A type epoxy resin described in embodiment 2 is bisphenol A type epoxy resin 6101, and described cashew nut shell oil solidifying agent is cashew nut shell oil solidifying agent 2015, and described filler is that particle size is 500-800 The purpose is active silica powder, and the curing accelerator is a tertiary amine curing accelerator DMP-30.

Embodiment 3

[0037] The bisphenol A type epoxy resin described in embodiment 3 is bisphenol A type epoxy resin 634, and described cashew nut shell oil solidifying agent is cashew nut shell oil solidifying agent 2544, and described filler is that particle size is 400-600 The purpose is active silica powder, and the curing accelerator is a tertiary amine curing accelerator N-benzyldimethylamine.

Embodiment 4

[0038] Bisphenol A type epoxy resin described in embodiment 4 is bisphenol A type epoxy resin 618, and described cashew nut shell oil curing agent is cashew nut shell oil curing agent 2041 and cashew nut shell oil curing agent 2015, both The weight ratio is 7:3, the filler is active silica powder with a particle size of 500-800 mesh, and the curing accelerator is a tertiary amine curing accelerator DMP-30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com