Method for using domestic carbon fiber to prepare high-performance carbon-based composite material through rapid directional infiltration

A composite material and carbon fiber technology, applied in metal material coating process, gaseous chemical plating, coating, etc., to achieve the effects of improving utilization rate, avoiding gas retention, and shortening the preparation process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

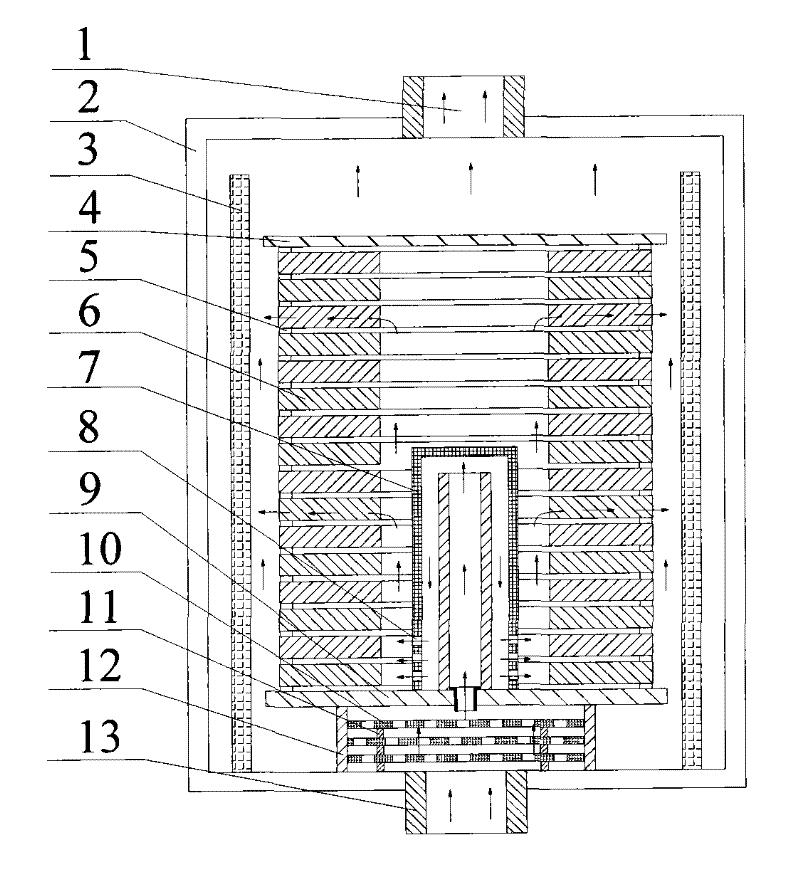

[0035] Its chemical vapor deposition equipment such as figure 1 As shown, the method of the present invention is carried out in the high-performance carbon-based composite material rapid directional infiltration airflow control equipment. The carbon fiber adopts domestic carbon fiber and is implemented with domestic carbon fiber.

[0036] The invention discloses a method for preparing a high-performance carbon-based composite material by rapid directional infiltration of domestic carbon fibers. The specific steps of the method are as follows:

[0037] Step 1: putting the carbon fiber preform into 70% nitric acid for oxidation treatment at 80° C. for 2 hours.

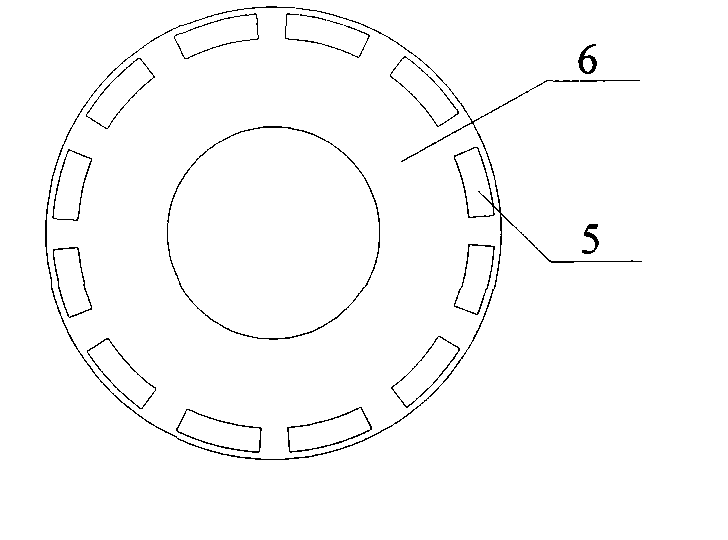

[0038] Step 2: The carbon fiber prefabricated body 6 has an outer diameter of 420mm, an inner diameter of 250mm, a thickness of 24mm, and an initial density of 0.45g / cm 3 , stably placed on the graphite circular plate 9, each prefabricated body is spaced apart with a graphite gasket 5, 40 graphite prefabricated bodies ...

Embodiment 2

[0043] Its chemical vapor deposition equipment such as figure 1 As shown, the method of the present invention is carried out in the high-performance carbon-based composite material rapid directional infiltration airflow control equipment. The carbon fiber adopts domestic carbon fiber and is implemented with domestic carbon fiber.

[0044] A method for preparing high-performance carbon-based composite materials by rapid directional infiltration of domestic carbon fibers. The specific steps of the method are as follows:

[0045] Step 1: put the domestic carbon fiber preform in 70% nitric acid for oxidation treatment at 80°C for 2 hours.

[0046]Step 2: The domestic carbon fiber preform 6 has an outer diameter of 45mm, an inner diameter of 280mm, a thickness of 23mm, and an initial density of 0.55g / cm 3 , stably placed on the graphite circular plate 9, each prefabricated body is spaced apart with a graphite gasket 5, 40 graphite prefabricated bodies are loaded at a time, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com