Push-pull device and method

A push-pull device and clamping device technology, applied to railway car body parts, locomotives, etc., can solve problems such as less than 100, long moving time of heavy objects, cumbersome operations, etc., to meet reliability and accuracy, and ensure rapid efficiency, satisfying the effect of simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

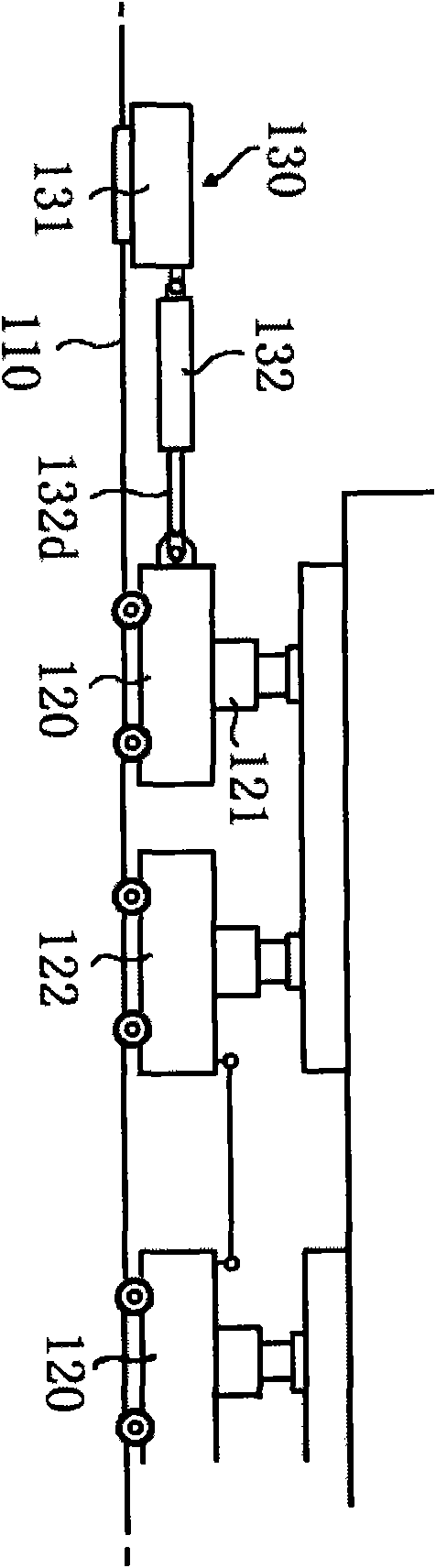

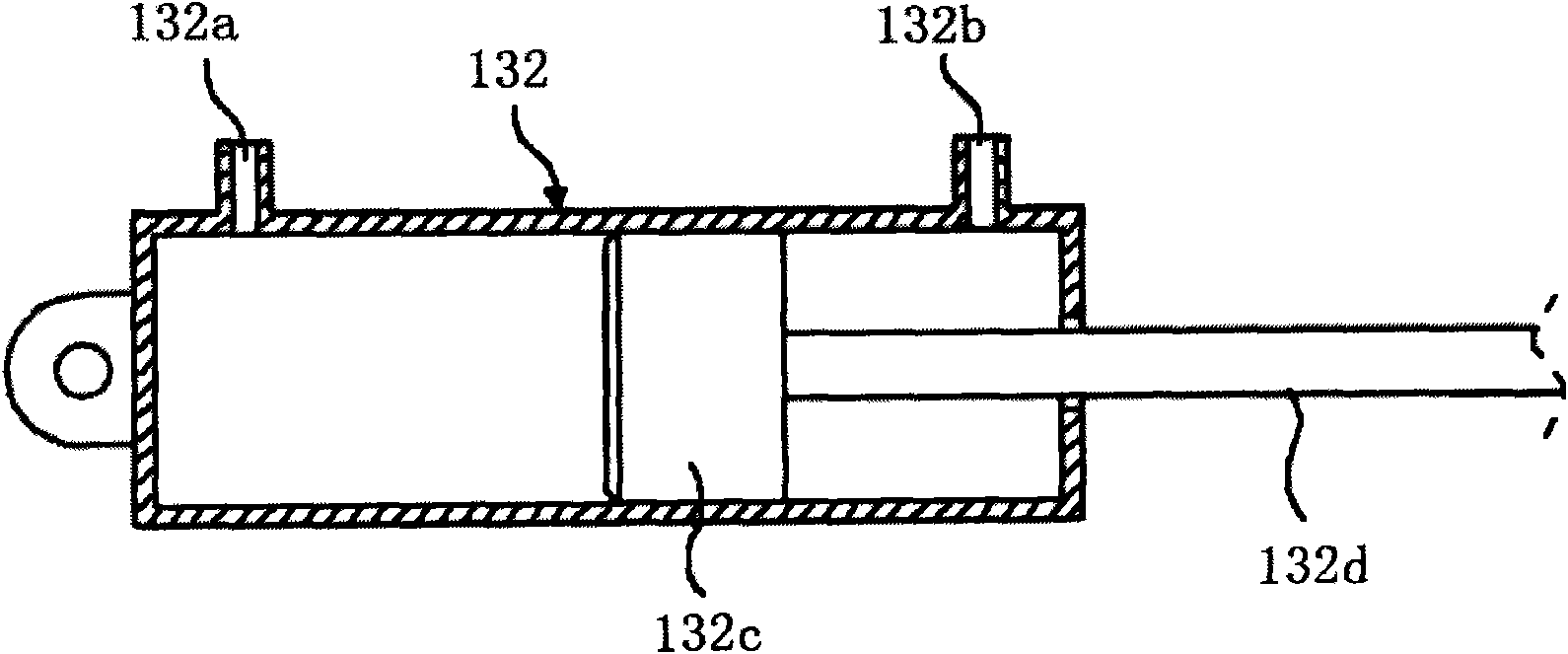

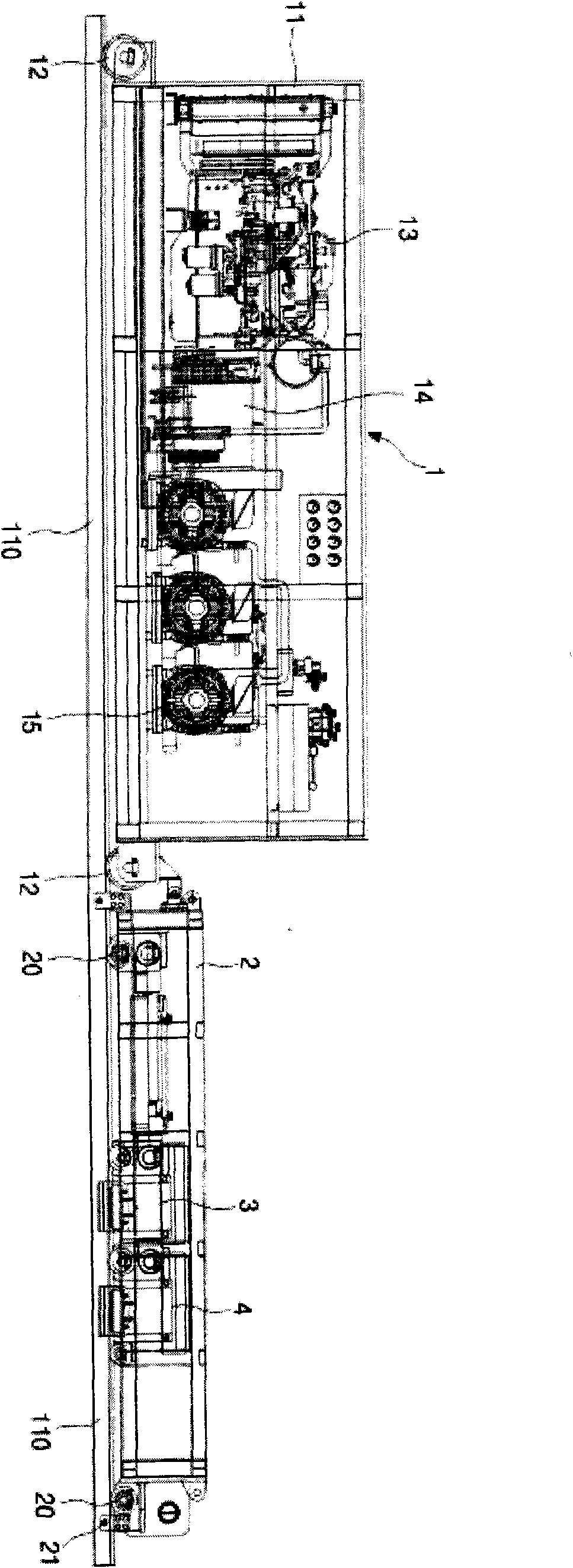

[0047] The invention is a push-pull device for transferring heavy objects. In detail, it is a push-pull device that makes the force of pushing or pulling the trolley with the heavy object on the slide rail the same, so that the trolley can transport the heavy object by pushing or pulling. In order to move the frame cover (2) with guide wheels (20) on the front and rear sides on the slide rail (110); the piston rod (3d) is installed in the same direction on the inside of the frame cover (2), and the majority of hydraulically actuated The push-pull hydraulic cylinder (3); the clamping device (4) that is installed on the rear side of the above-mentioned push-pull hydraulic cylinder (3) to fix or release the push-pull hydraulic cylinder (3) to the slide rail (110); the trolley moves the heavy object When it is necessary to run in the opposite direction, unlike other devices such as hoists in the past, only the push-pull device can achieve the effect of simplicity and efficiency of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com