Honing method and honing machine

A honing and machine technology, which is applied in the field of honing technology, can solve problems such as motion delay, load instability, and abrasive grain shedding of honing stones, and achieve the effects of soft feeding and stretching motion, uniform processing load, and stable accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

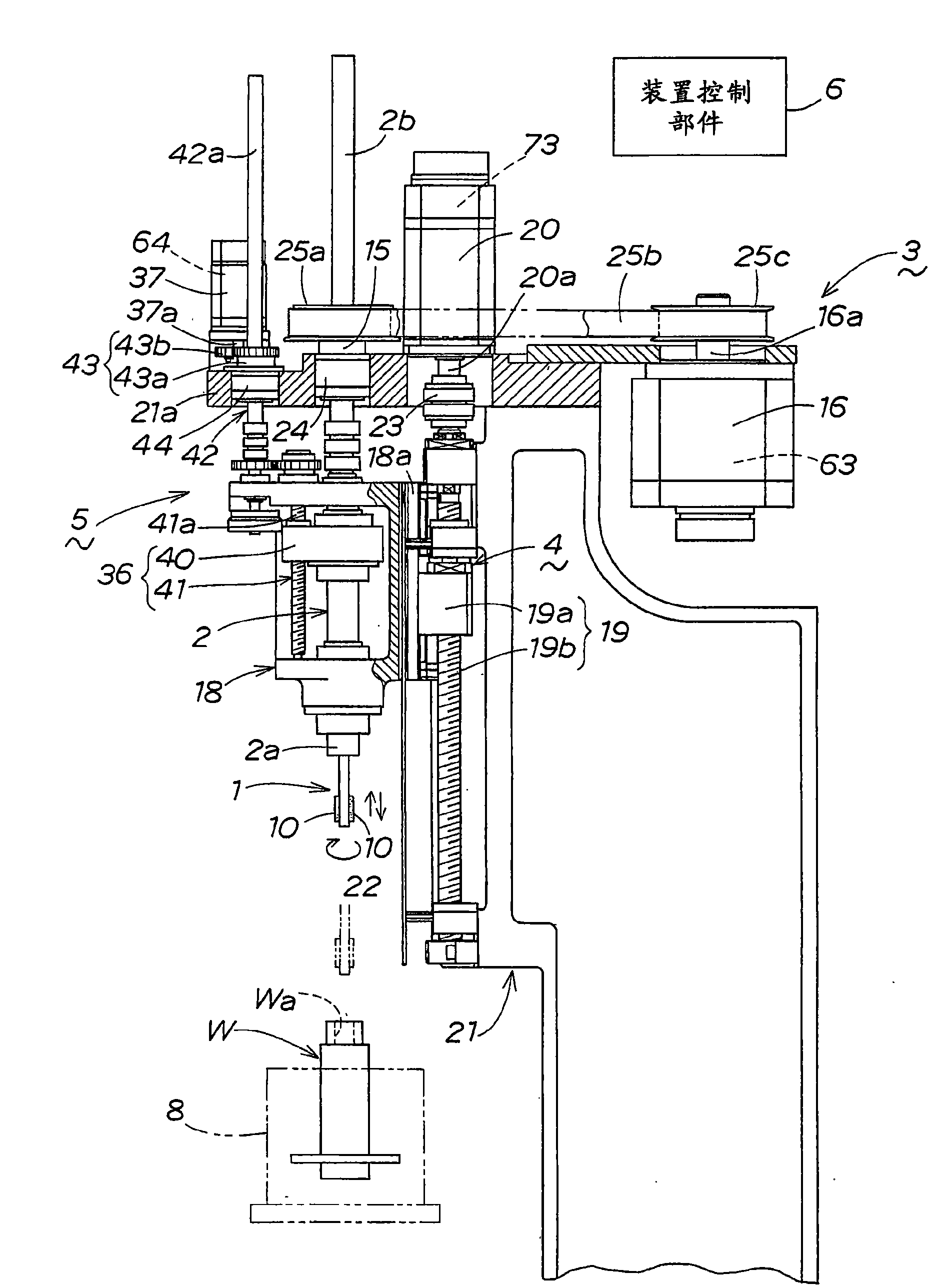

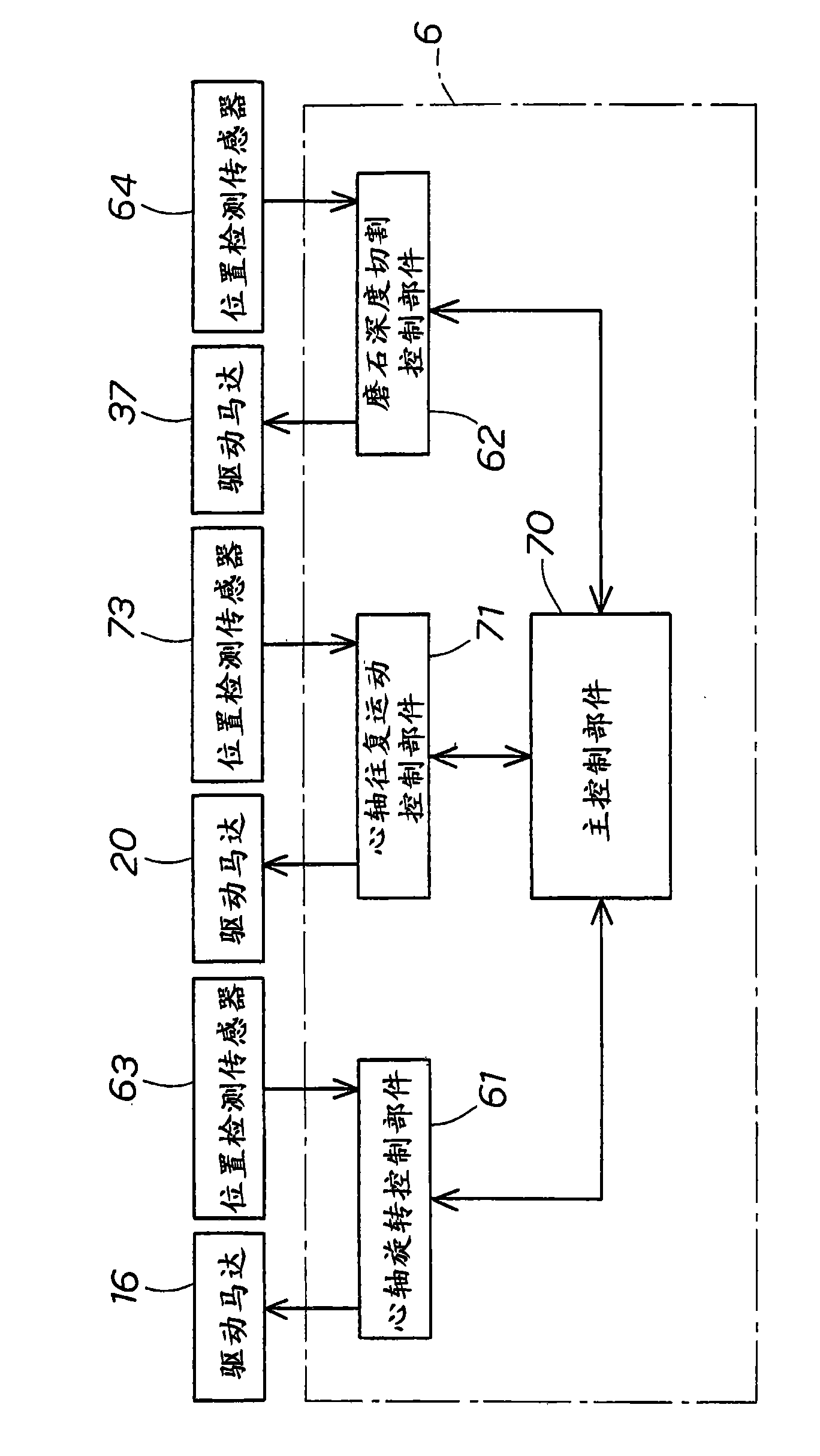

[0049] figure 1 The honing machine of the present invention is shown in , specifically, the honing machine is used for machining the inner circumference Wa of the cylindrical machining hole of the workpiece W, and mainly includes a rotating spindle 2 with a honing tool 1 at the front end, a spindle Shaft rotation drive part (mandrel rotation device) 3 , mandrel reciprocation drive part (mandrel reciprocation device) 4 , grindstone depth cutting part (grindstone depth cutting device) 5 and device control part (control device) 6 .

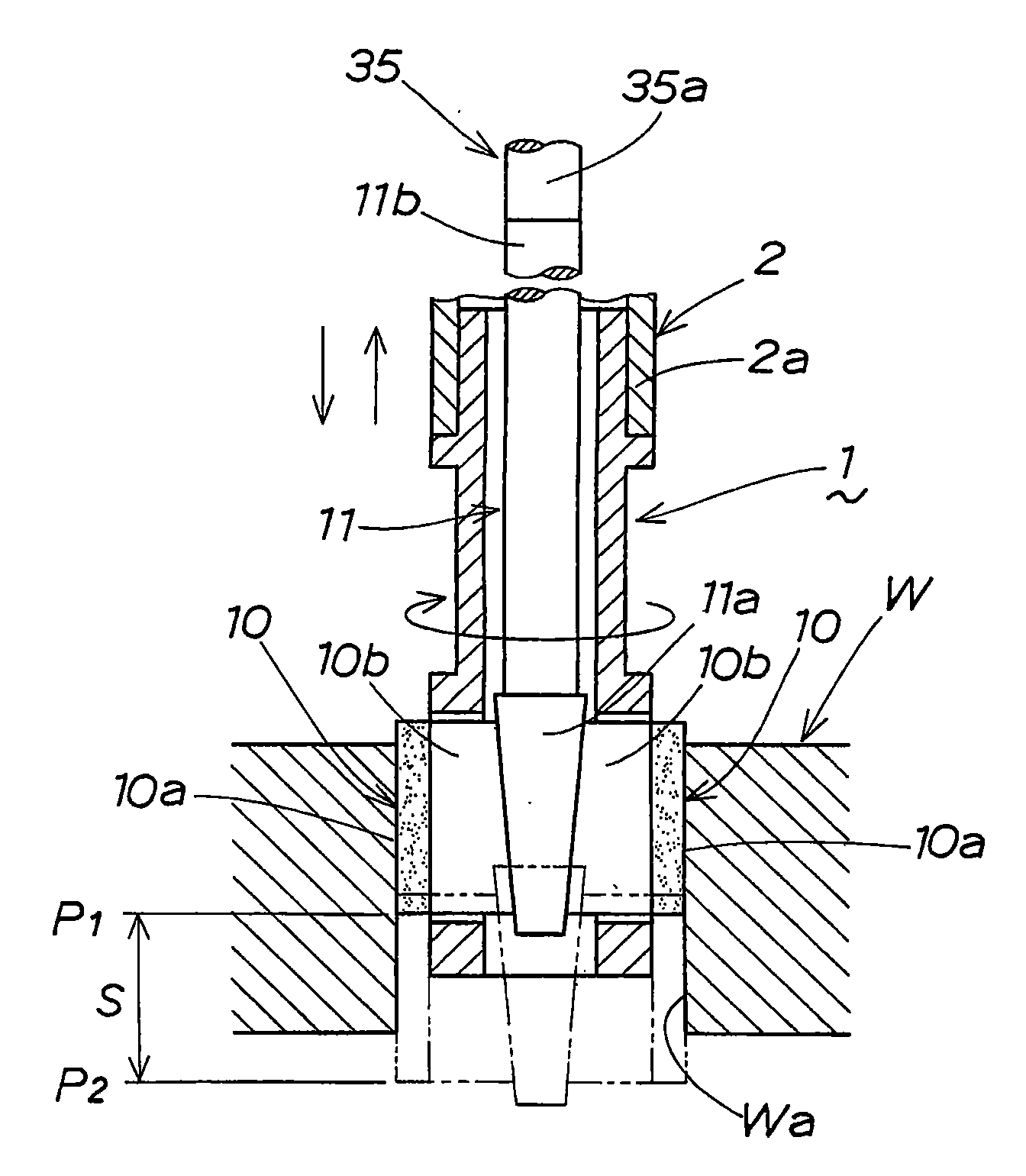

[0050] A honing tool (or honing head) 1 is detachably fitted on the front end of the rotary spindle 2, that is, at the bottom end 2a.

[0051] like figure 2 As shown in , the interior of this honing tool 1 includes: a plurality of honing stones 10. 10, ..., these honing stones are arranged to freely expand and contract in the radial direction; a tapered rod 11, with for extending and contracting these honing stones 10, 10, .

[0052] Each honing...

Embodiment 2

[0105] Figure 7 The preferred embodiment is shown in , which is similar to preferred embodiment 1, except that the position waveforms in the feeding and extending motions of the honing stones 10, 10, . . . are changed.

[0106] That is, in this preferred embodiment, the position waveform in the raising and lowering stroke motion of the honing tool 1 is a triangular waveform ( Figure 7 Middle dotted line waveform), the position waveform in the feeding and extending motion of the honing stone 10, 10, ... is a linear waveform, so as to be synchronized and coordinated with the triangular waveform ( Figure 7 The solid line waveform in ).

[0107] More specifically, the raising and lowering stroke speeds of the honing tool 1 are specific uniform strokes in the raising stroke and lowering stroke, while the feed and extension amounts of the honing stones 10, 10, . . . are set For a specific depth of cut per stroke of the raising and lowering (reciprocating) movement of the honing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com