Ploughing in green device of green manure

A technology for turning green and green manure, which is applied in the application, tillage equipment, agricultural machinery and implements, etc., can solve the problems of poor green coverage, high cost, large soil disturbance, etc. Bottom undulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

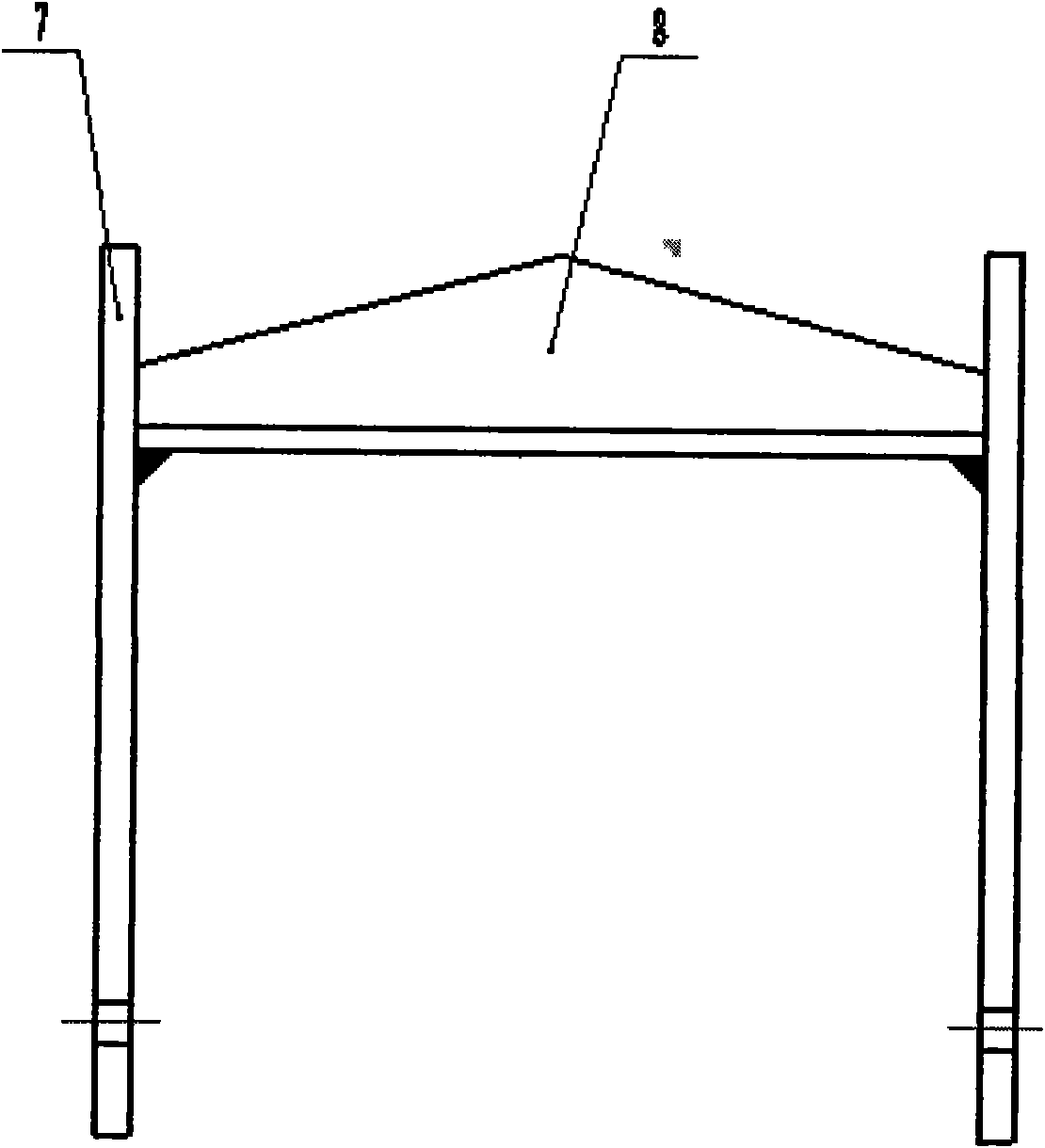

[0024] The design of the present embodiment is used for the paddy field green manure turning green device of green manure crops such as milk vetch.

[0025] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0026] according to figure 1 It can be seen that the green manure turning green device of this embodiment includes 3 groups of rotary soil cutting units and 3 groups of soil unloading and embedding units. The rotary soil cutting unit is connected to the knife seat outside the cutter head by bolts, and the knife seat is welded on the outside of the cutter head. The soil unloading and embedding unit is connected to the inner side of the cutterhead by bolts. The cutter head is connected with the cutter head flange through bolts; the cutter head flange is welded on the cutter shaft.

[0027] The rotary soil cutting unit includes 2 side knives and 1 horizontal knife. The edge of the side knife is in the shape of an A...

Embodiment 2

[0032] The design plowing depth of the greening device in this embodiment is 200mm, the soil cutting pitch is 150mm, the forward speed of the unit is 2.1Km / h, the rotational speed of the cutter shaft is 76r / min, the turning radius of the side cutter is 300mm, and the turning radius of the side plate is 240mm According to above-mentioned several parameters, can obtain by analyzing the fish cycloid of rotary graph cutting device, the installation angle between the rotary soil cutting unit in the present embodiment and unloading soil embedding green unit is 58 °; The included angle is 120°, and the implementation results show that the herringbone-shaped horizontal knife can also better complete the greening work when the included angle is 120°.

Embodiment 3

[0034] In this embodiment, the design plowing depth of the greening device is 200mm, the soil cutting pitch is 150mm, the unit advance speed is 2.1Km / h, the cutter shaft speed is 56r / min, the turning radius of the side cutter is 380mm, and the side plate The turning radius is 320mm. According to the above parameters, by analyzing the trochoid of the rotary cutting device, it can be obtained that the installation angle between the rotary soil cutting unit and the soil unloading and embedding unit in this embodiment is 40°. The side knives are straight knives, and the two side knives correspondingly installed on the two cutter heads are installed at an angle of 30°. The implementation results show that the greening work can be better completed after the cutter shaft speed is reduced.

[0035] The quantity of the rotary soil cutting unit and the soil unloading and embedding unit installed on each cutterhead of the present invention, and the axial distance between the flanges of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com