Control method of optimized running of combined cooling and power distributed energy supply system of micro gas turbine

A micro gas turbine, combined cooling and power technology, which is applied in the directions of gas turbine installations, machine operation, electrical program control, etc. problem, to achieve the effect of high primary energy utilization index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

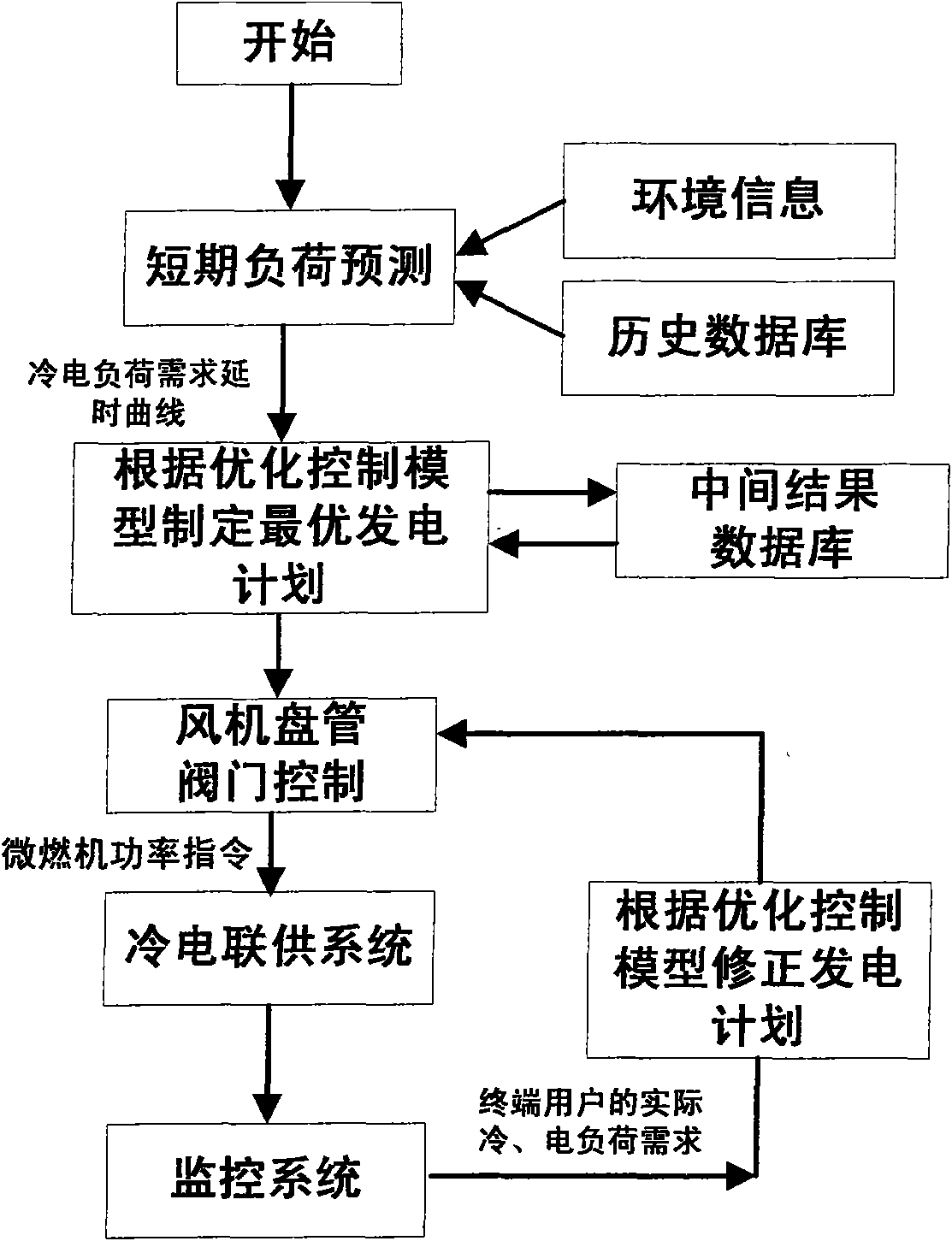

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

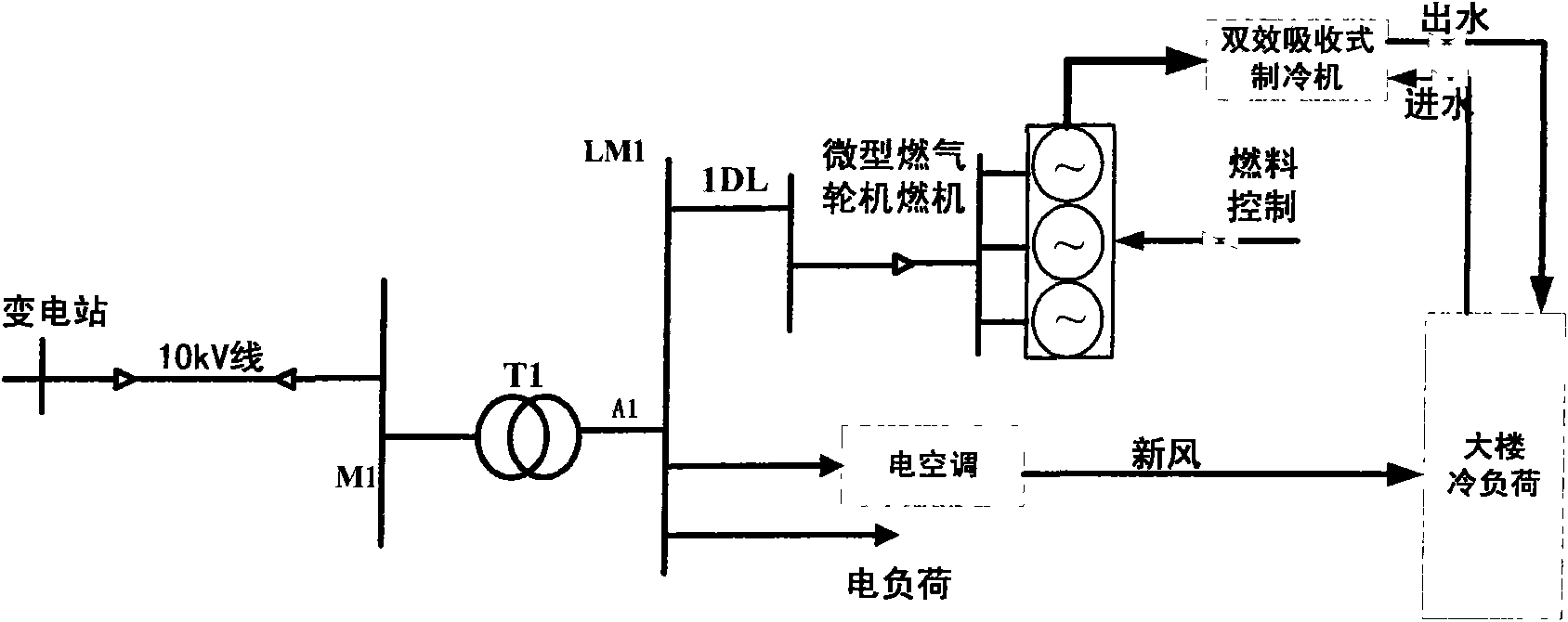

[0028] figure 1 The cooling and power supply system structure diagram of the end user is given. The electric loads of the end users, the central electric air conditioner and the micro-combustion unit are connected to the low-voltage bus. The combined cooling and power supply system adopts fan coil unit design to supply cooling to end users, and the central electric air conditioner adopts a full-air system. When the cogeneration system cannot meet the cooling load demand of end users, the cogeneration system can no longer supply cooling to some rooms equipped with electric air conditioners by controlling the cold water pipe valves in some rooms. Air conditioning is adequate.

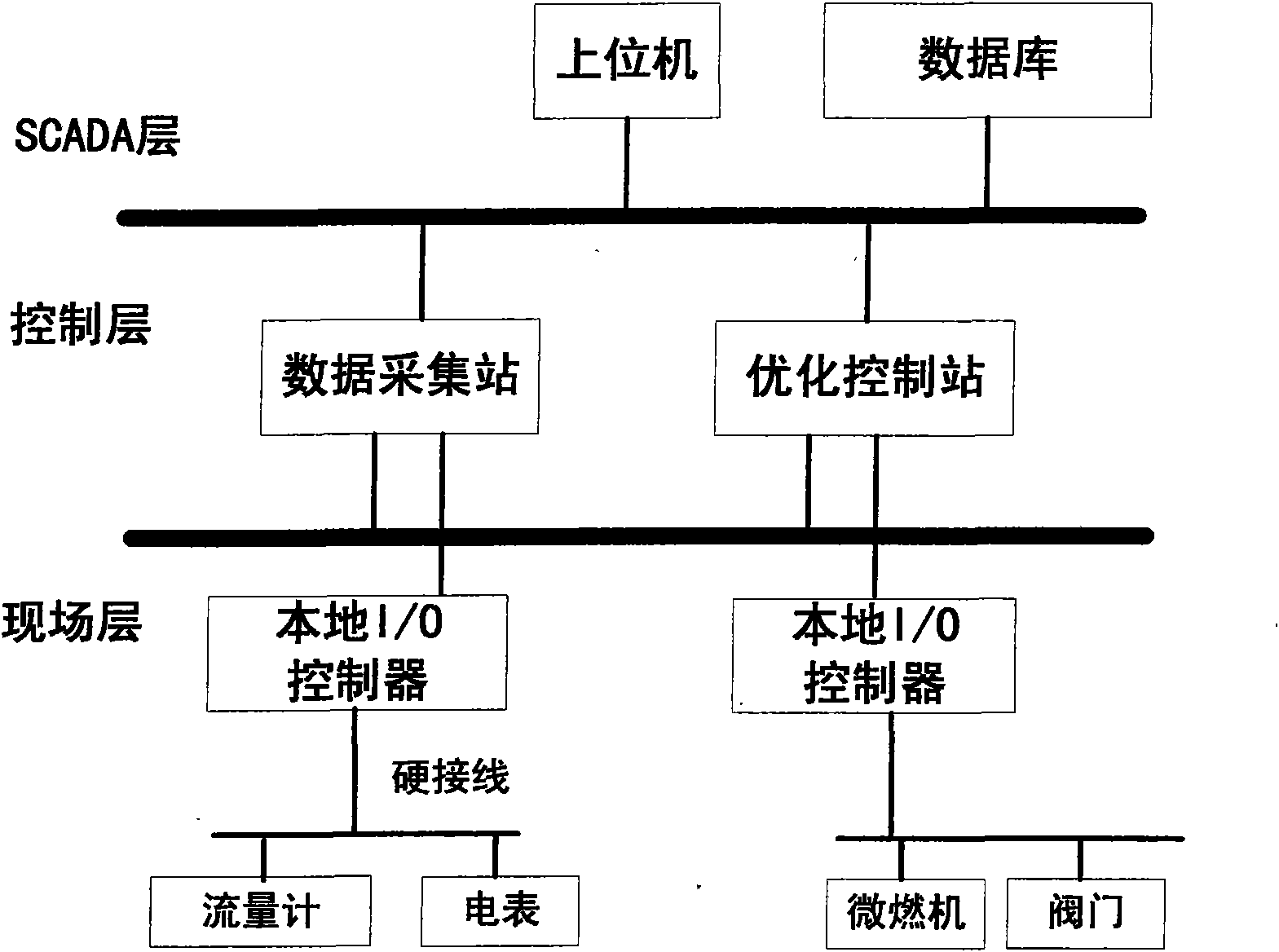

[0029]The entire optimization control system is composed of hardware and software: the hardware part is a distributed monitoring system, and the system structure is as follows: figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com