Design method of converter cast iron water-cooling mouth

A design method and molten iron technology, applied in the manufacture of converters, etc., can solve the problems of easy cracks in the inner ring, inconvenient repairs, short service life, etc., and achieve the effect of not easy to stick to slag removal, not easy to deform, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] A preferred embodiment of the present invention will be specifically introduced below in conjunction with the accompanying drawings.

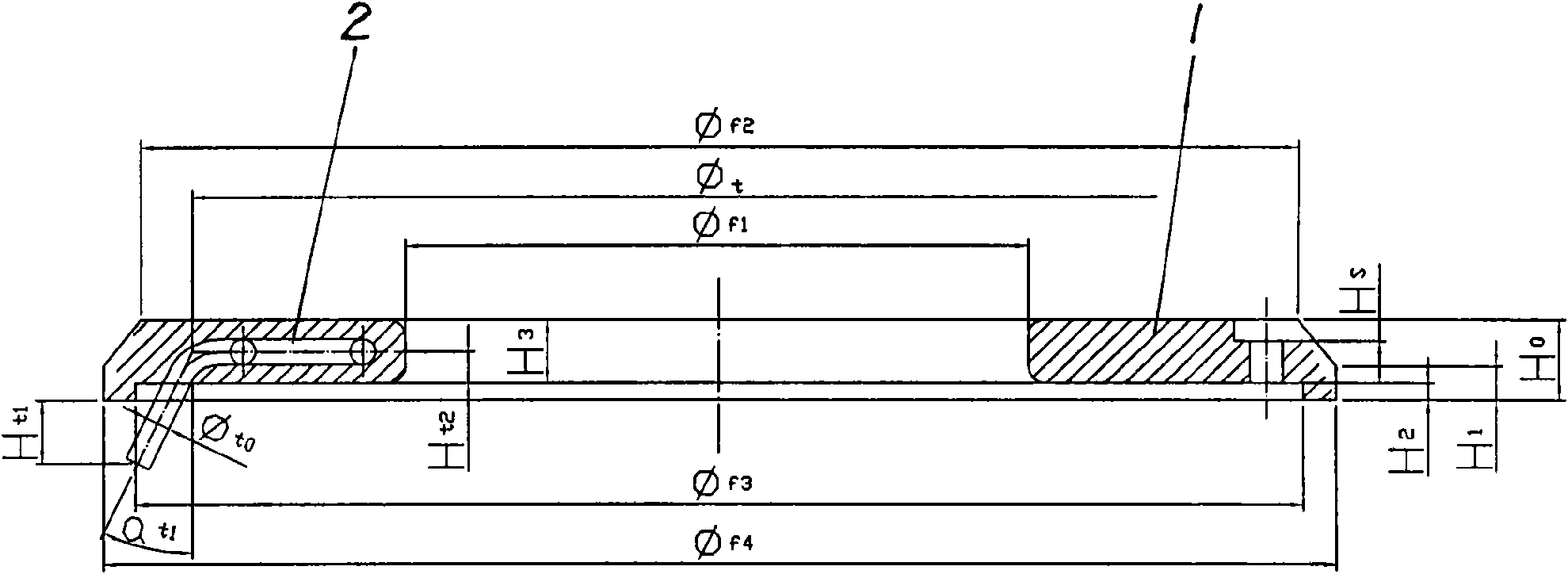

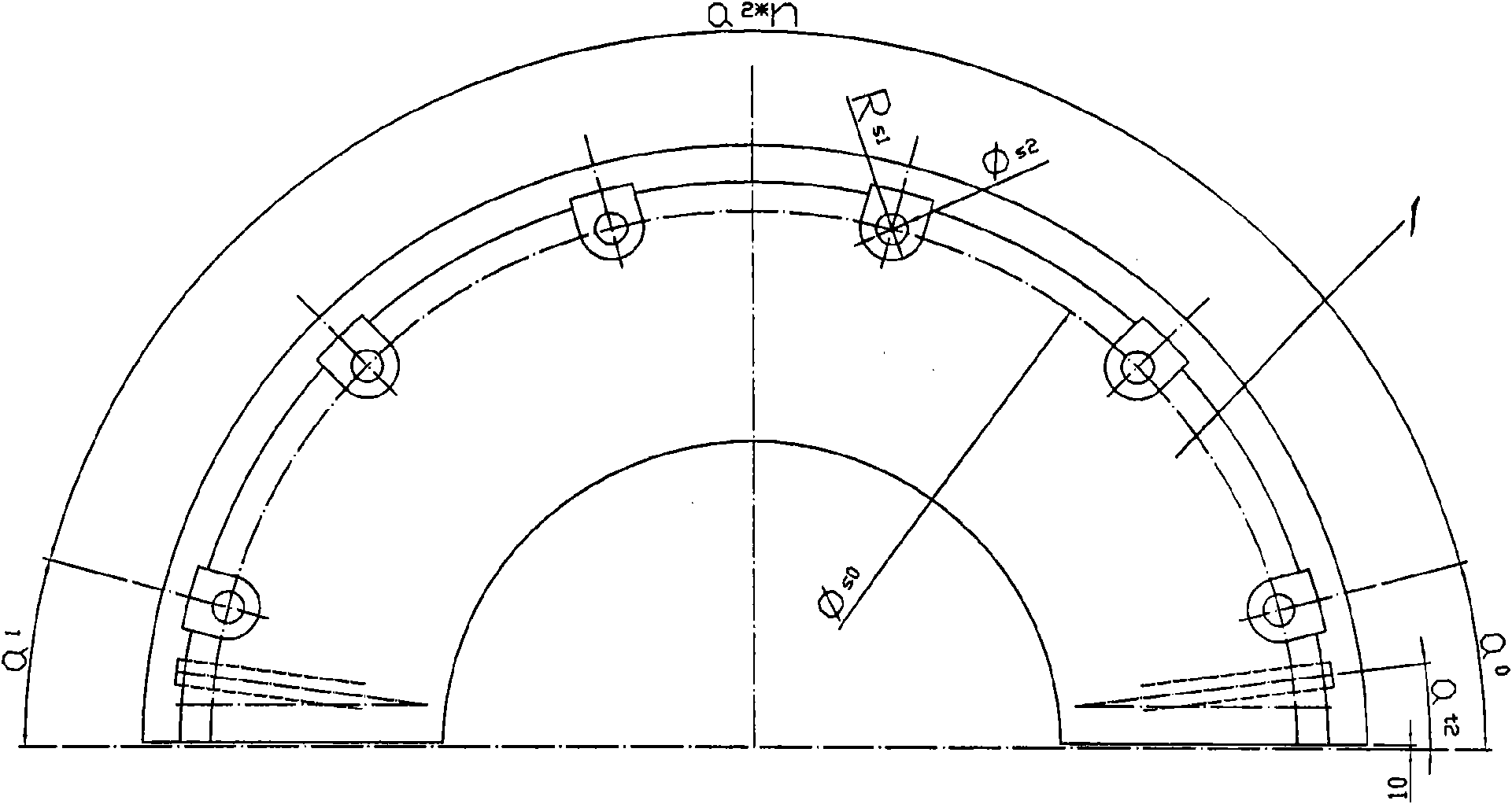

[0057] figure 1 with figure 2 It shows a design structure of a converter cast iron water-cooled furnace mouth in an embodiment of the present invention.

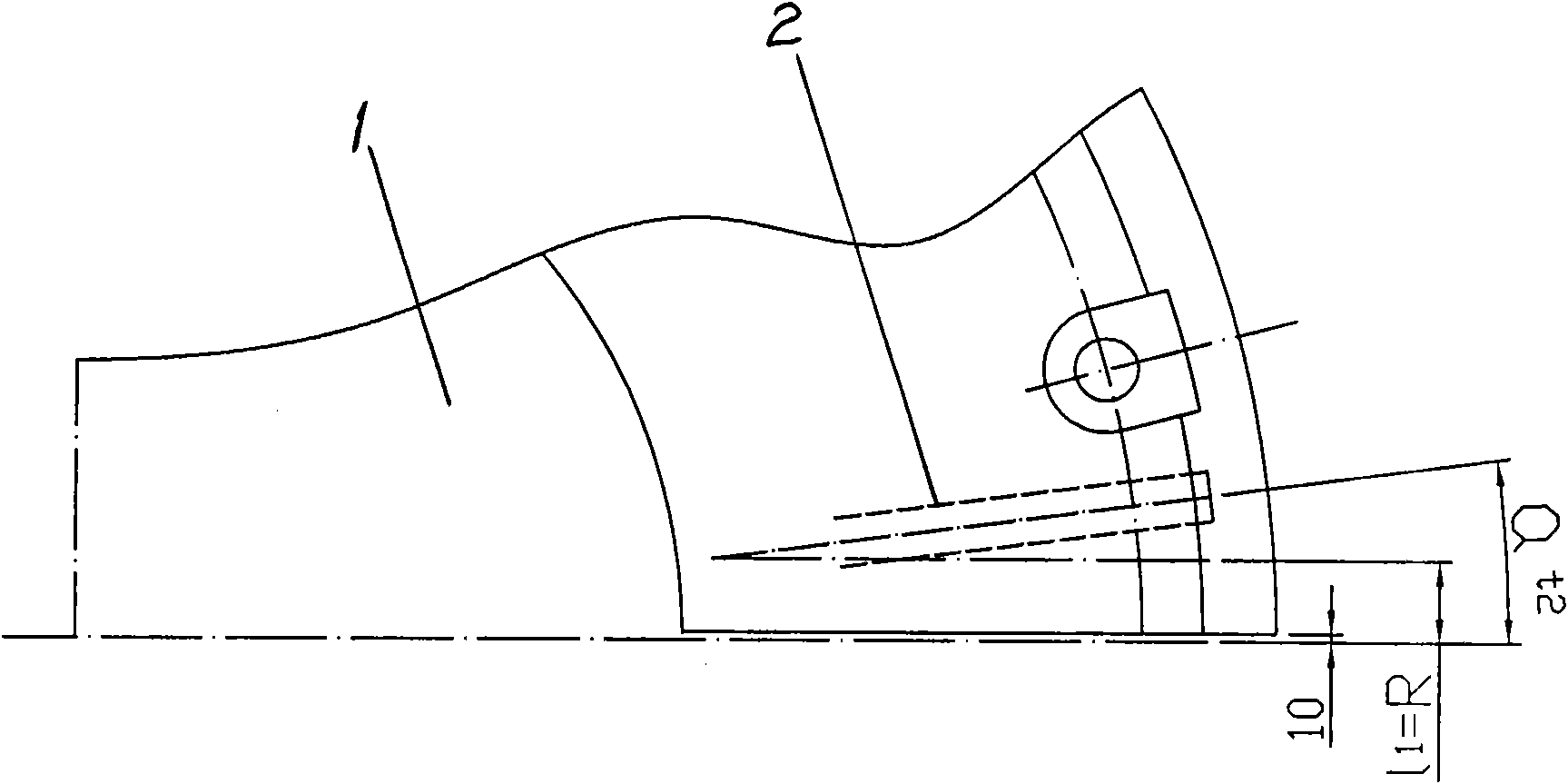

[0058] image 3 It shows the design structure of the outlet at the end of the cooling pipe of the converter cast iron water-cooled furnace mouth in the embodiment of the present invention.

[0059] Figure 4 It shows the structure of the first embodiment of the converter cast iron B-type water-cooled furnace mouth in the embodiment of the present invention.

[0060] Figure 5 It shows the structure of the second embodiment of the converter cast iron B-type water-cooled furnace mouth in the embodiment of the present invention.

[0061] see Image 6 with Figure 7 , according to the design method of a kind of converter cast iron water-cooled burner mouth of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com