Working slurry of stop-grouting plug for mine ground pre-grouting

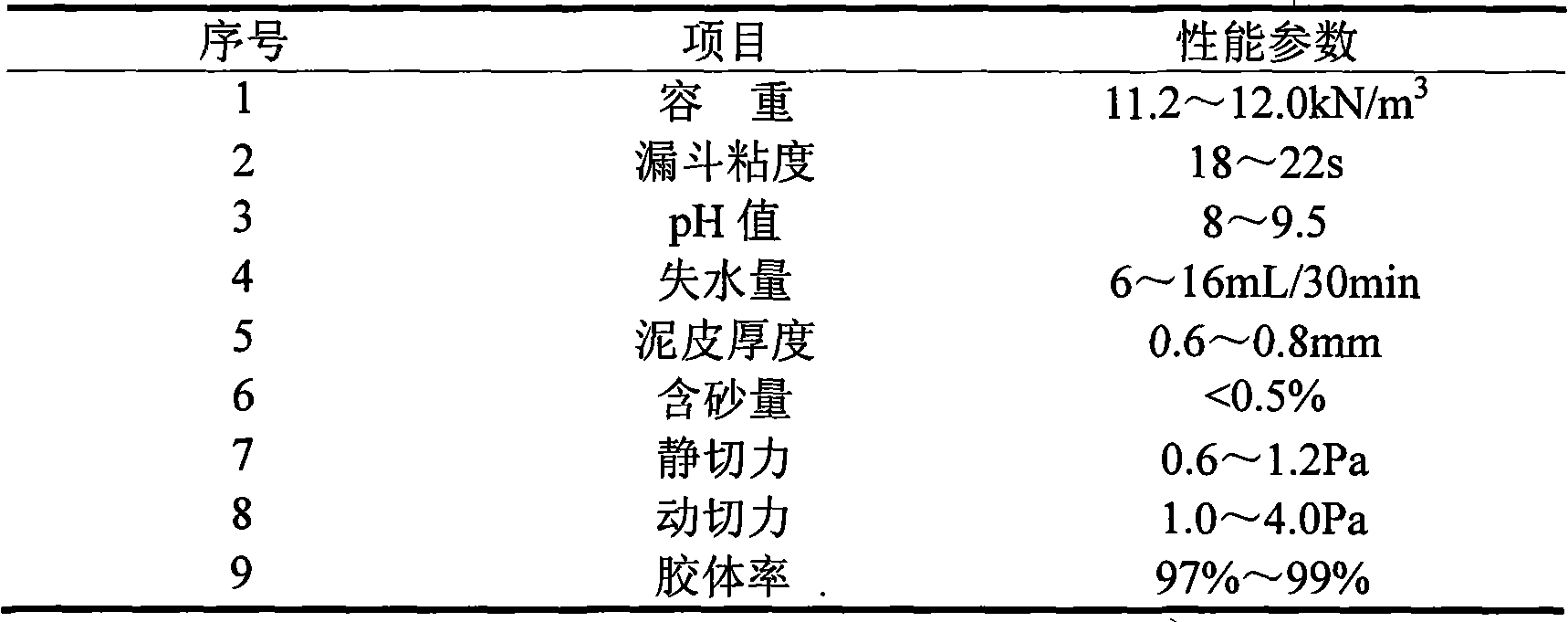

A technology of pre-grouting and grouting plug is applied in the field of working mud of pre-grouting and grouting plug on mine ground, which can solve the problems of unsuitable pre-grouting construction, long mud treatment period and high cost, and meet the requirements of high mud performance. , The effect of suppressing collapse and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, the present invention uses fresh water and bentonite as basic raw materials, with soda ash, sodium carboxymethyl cellulose, potassium humate, sucrose, anti-slump lubricant as treatment agent, and when the collapse-off block phenomenon is serious, add anti-slump lubricant, Configure 1m 3 Mud, the quality of each component is:

[0019] Water: 910kg

[0020] Bentonite: 200kg

[0021] Soda ash: 3.5kg

[0022] Sodium carboxymethyl cellulose: 0.1kg

[0023] Potassium humate: 1.5kg

[0024] Sucrose: 1.0kg

[0025] Anti-slump lubricant: 0.8kg

[0026] The viscosity of the mud funnel is 18s, the water loss is 12mL / 30min, and the thickness of the mud skin is 0.7mm. After mixing with the single-liquid cement slurry, the initial setting time of the single-liquid cement slurry is extended to 17h, and the final setting time is extended to 203h.

Embodiment 2

[0027] Embodiment 2, the present invention uses fresh water and bentonite as basic raw materials, with soda ash, sodium carboxymethyl cellulose, potassium humate, sucrose as treatment agent, configures 1m 3 Mud, the quality of each component is:

[0028] Water: 894kg

[0029] Bentonite: 250kg

[0030] Soda ash: 4.0kg

[0031] Sodium carboxymethyl cellulose: 0.1kg

[0032] Potassium humate: 1.8kg

[0033] Sucrose: 1.4kg

[0034] The viscosity of the mud funnel is 19s, the water loss is 9mL / 30min, and the thickness of the mud skin is 0.6mm. After mixing with the single-liquid cement slurry, the initial setting time of the single-liquid cement slurry is extended to 19.5h, and the final setting time is extended to 280h.

Embodiment 3

[0035] Embodiment 3, the present invention uses fresh water and bentonite as basic raw materials, with soda ash, sodium carboxymethyl cellulose, potassium humate, sucrose, and anti-slump lubricant as treatment agents, and configures 1m 3 Mud, the quality of each component is:

[0036] Water: 875kg

[0037] Bentonite: 300kg

[0038] Soda ash: 4.0kg

[0039] Sodium carboxymethyl cellulose: 0.1kg

[0040] Potassium humate: 2.0kg

[0041] Sucrose: 1.8kg

[0042] Anti-slump lubricant: 1.0kg

[0043] The viscosity of the mud funnel is 22s, the water loss is 13mL / 30min, and the thickness of the mud skin is 0.8mm. After mixing with the single-liquid cement slurry, the initial setting time of the single-liquid cement slurry is extended to 23h, and the final setting time is extended to 315h.

[0044] Before stopping the slurry in the bedrock section and pulling the plug, the water loss of the mud should be adjusted to within the range of 6-10mL / (30min), the thickness of the mud sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com