Manufacture process of thermal insulation bucket of hard composite graphite felt for single crystal furnace

A composite graphite, thermal insulation technology, applied in the direction of single crystal growth, manufacturing tools, applications, etc., can solve the problems of poor oxidation resistance, short service life, large space occupation, etc., achieves easy heating and cooling, and saves space in the furnace , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

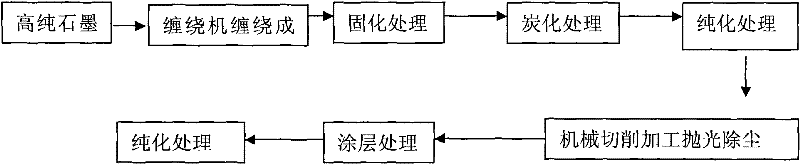

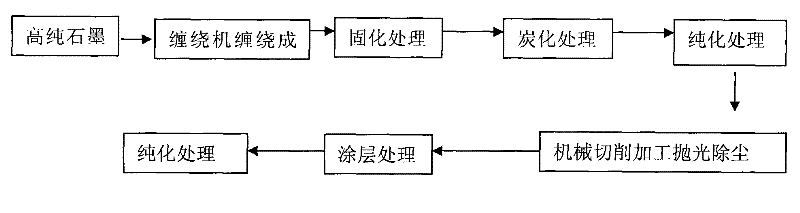

[0026] like figure 1 As shown, the high-purity graphite felt (produced by Gansu Haoshi Carbon Fiber Co., Ltd.) treated at 2200°C was selected as the green body material. Make molds according to the corresponding single crystal furnace size (16#, 18#, 20#, 24#), and the green body material is wound and formed by brushing adhesive while winding at the rotation rate of 1 circle / 30s by the automatic winding machine, so that The structure between the felt layers is tight and it is not easy to delaminate; then after curing treatment, that is, in the high-temperature purification furnace, the green body is heated to 210°C at a constant temperature of 2 hours and cooled to 60°C at a heating rate of 30°C / h. The body is solidified and shaped; the body is purified again, that is, nitrogen is passed into the high-temperature purification furnace 2 with Cl 2 The gas is heated to 2200°C at a heating rate of 30°C / h for purification treatment; after purification treatment, the formed body i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com