Manufacture process of thermal insulation bucket of hard composite graphite felt for single crystal furnace

A composite graphite, thermal insulation technology, applied in the direction of single crystal growth, manufacturing tools, applications, etc., can solve the problems of poor anti-oxidation performance, insufficient accuracy, and poor adhesion, achieve easy heating and cooling, increase service life, Not easy to layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

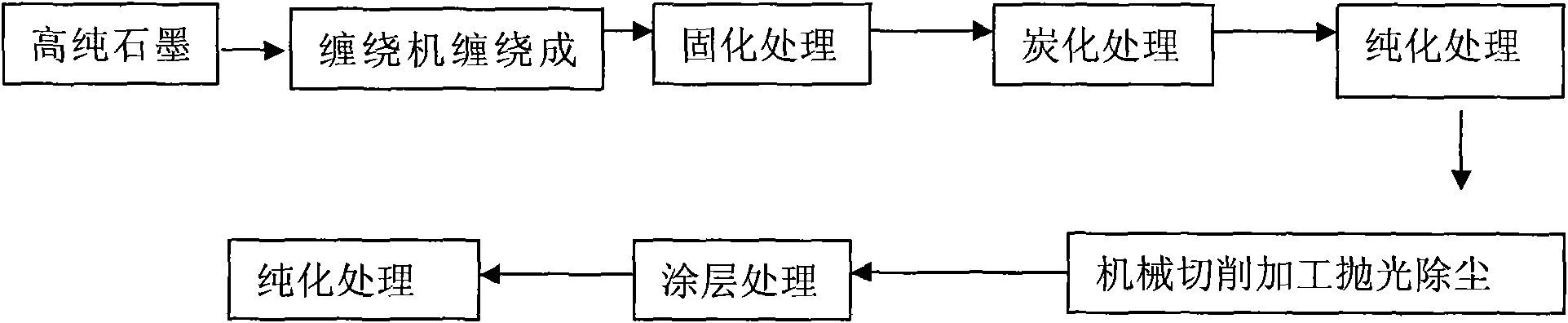

[0026] like figure 1 As shown, high-purity graphite felt (produced by Gansu Haoshi Carbon Fiber Co., Ltd.) treated at 2200° C. was selected as the green body material. According to the corresponding single crystal furnace size (16#, 18#, 20#, 24#), the mold is made, and the blank material is wound by an automatic winding machine at a rotation rate of 1 circle / 30s while brushing the adhesive and winding it to make the shape. The felt layer has a tight structure and is not easy to delaminate; then after curing, that is, in a high-temperature purification furnace, the green body is heated to 210 °C at a heating rate of 30 °C / h and cooled to 60 °C for 2 hours. The green body is solidified and formed; the green body is purified again, that is, N is introduced into the high temperature purification furnace. 2 with Cl 2 The gas is heated up to 2200°C at a heating rate of 30°C / h for purification treatment; the green body after purification treatment is formed; the surface is polishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com