Overhead outside opening gas distribution two-stroke engine

A two-stroke, engine technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of airflow fluidity, design restrictions on the air distribution opening time of the airflow flow area, etc., to achieve simple structure, improved efficiency, airflow The effect of increasing the degree of flow and gas mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

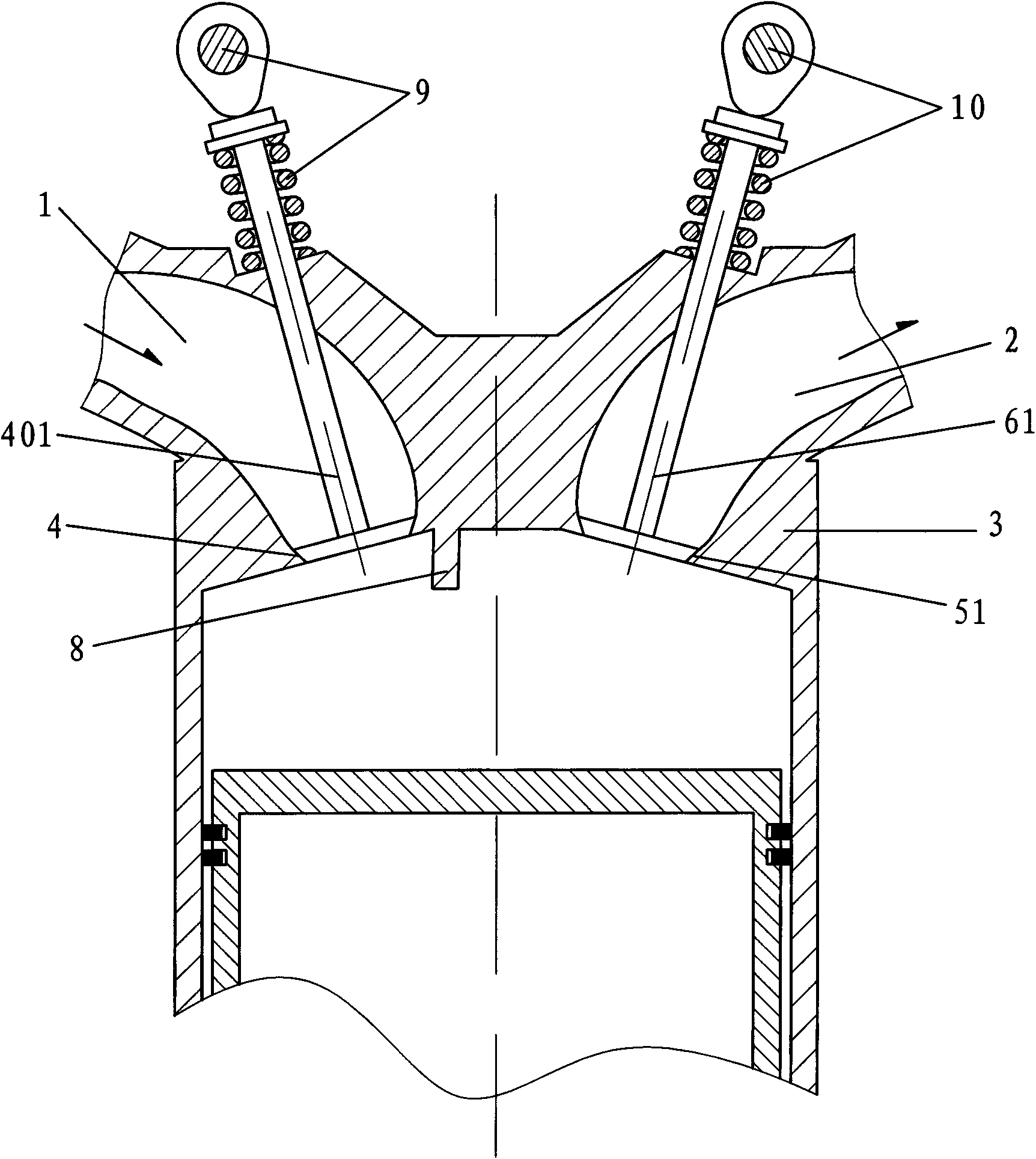

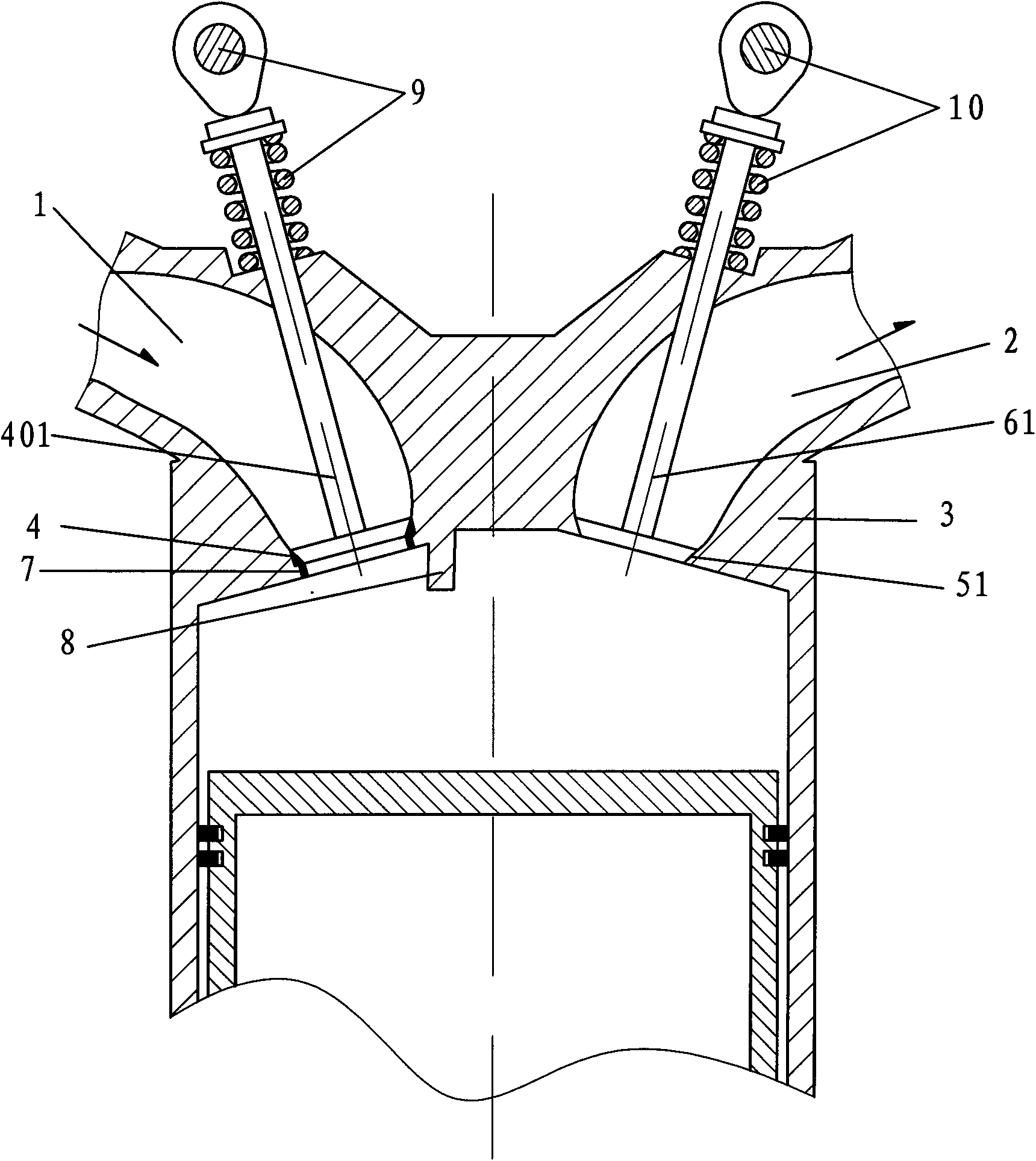

[0027] Such as figure 1 The shown overhead two-stroke engine with outwardly opening air distribution includes an intake port (1), an exhaust port (2) and a cylinder head (3). Seat opening (4), the reverse installation and outward opening air intake seat (4) communicates with the air inlet (1), and a reverse installation and outward opening is set at the reverse installation and outward opening air intake seat (4) The intake valve body (401), the cylinder head (3) is provided with a reverse-installed and outwardly opened exhaust seat (51), and the reverse-installed outwardly opened exhaust seat (51) is connected with the exhaust passage ( 2) Connected, a reversely installed outwardly opened exhaust valve body (61) is provided at the reversely installed outwardly opened exhaust seat (51), and a reversely installed outwardly opened air intake seat (4) is connected to the reversed A diversion structure (8) is arranged between the outer opening exhaust seat (51), and the reversed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com