Double-roller valve body adjusting type electronic throttle valve

An electronic throttle and adjustable technology, which is applied in the direction of engine control, machine/engine, internal combustion piston engine, etc., can solve the problems such as the difficulty of precise control of the throttle of racing cars, the unstable operation of the throttle, and the unbalanced force of the valve plate, etc., to achieve Improve work efficiency and stability, improve work stability, smooth transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

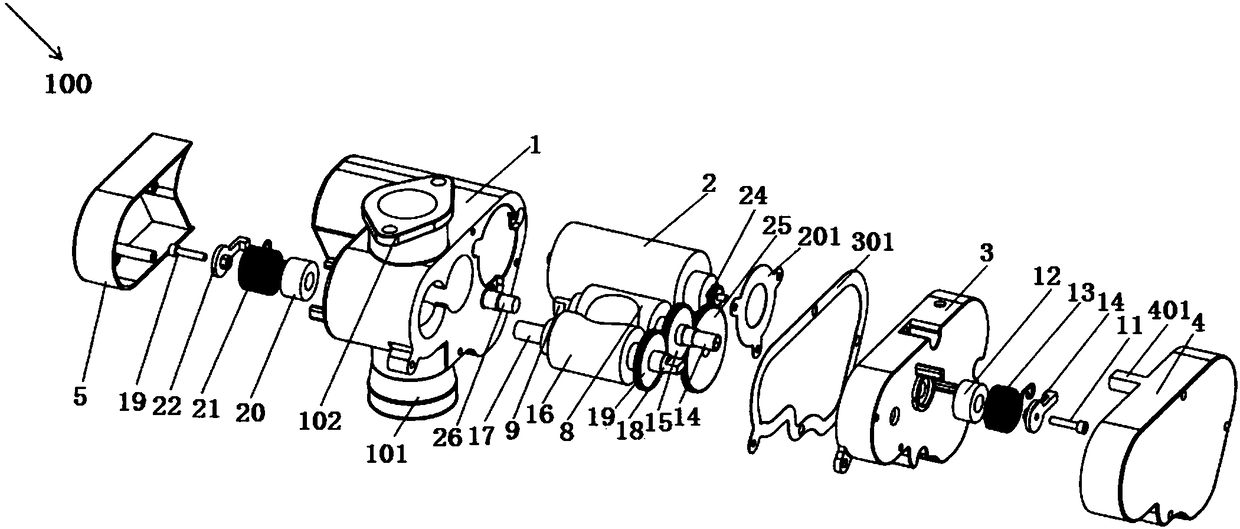

[0029] figure 1 It is a schematic diagram of the explosion of the dual-roller valve body adjustable electronic throttle in the embodiment of the present invention, figure 2 It is a side view of the structure of the dual roller valve body adjustable electronic throttle valve in the embodiment of the present invention.

[0030] Such as figure 1 and 2 As shown, a double-roller valve body adjustable electronic throttle 100 of this embodiment is used to control the intake air volume of a formula racing engine, and is characterized in that it includes: a throttle housing 1, a drum part, and a DC motor 2 , gear cover 3, front end cover 4 and rear end cover 5.

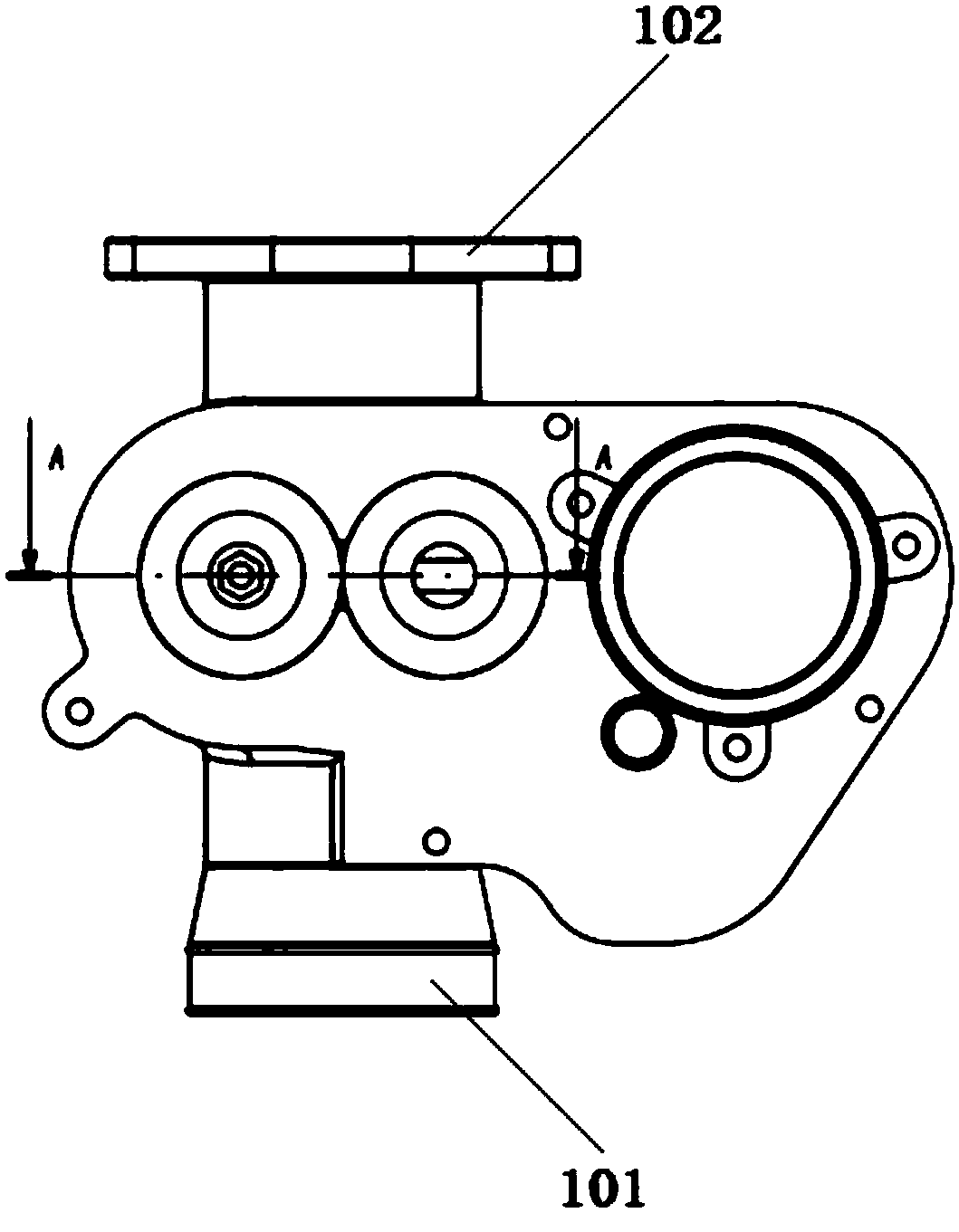

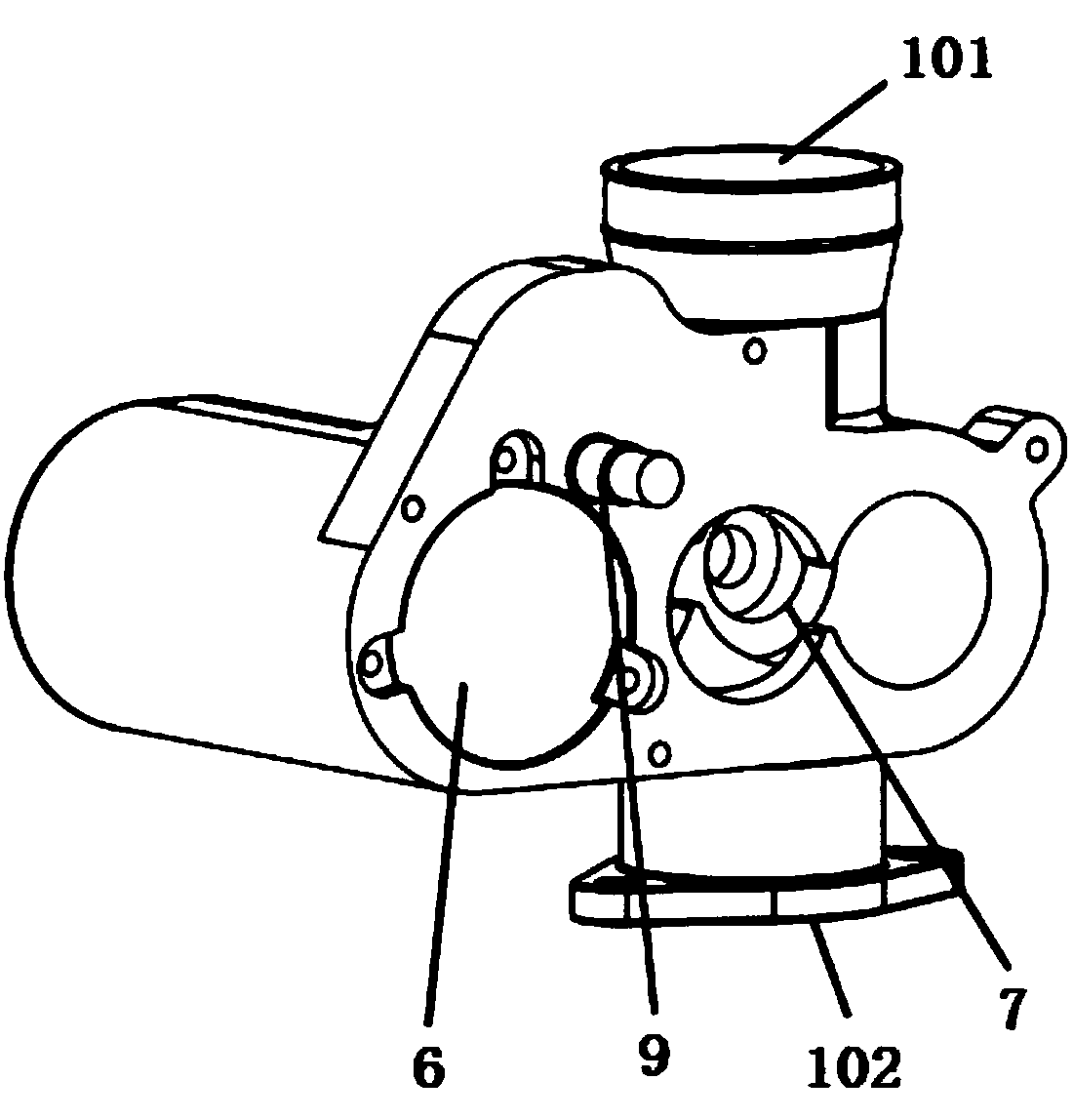

[0031] image 3 It is the left side view of the throttle housing of the double roller valve body adjustable electronic throttle in the embodiment of the present invention, Figure 4 It is a right side view of the throttle housing of the double roller body adjustable electronic throttle valve in the embodiment of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com