Vehicle-mounted SCR metering and ejecting system taking exhaust gas temperature as variable

A technology of exhaust gas temperature and injection system, applied in exhaust devices, air quality improvement, mechanical equipment, etc., can solve problems such as blockage and SCR conversion efficiency decline, and achieve the effect of eliminating NOX, easy industrial application, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

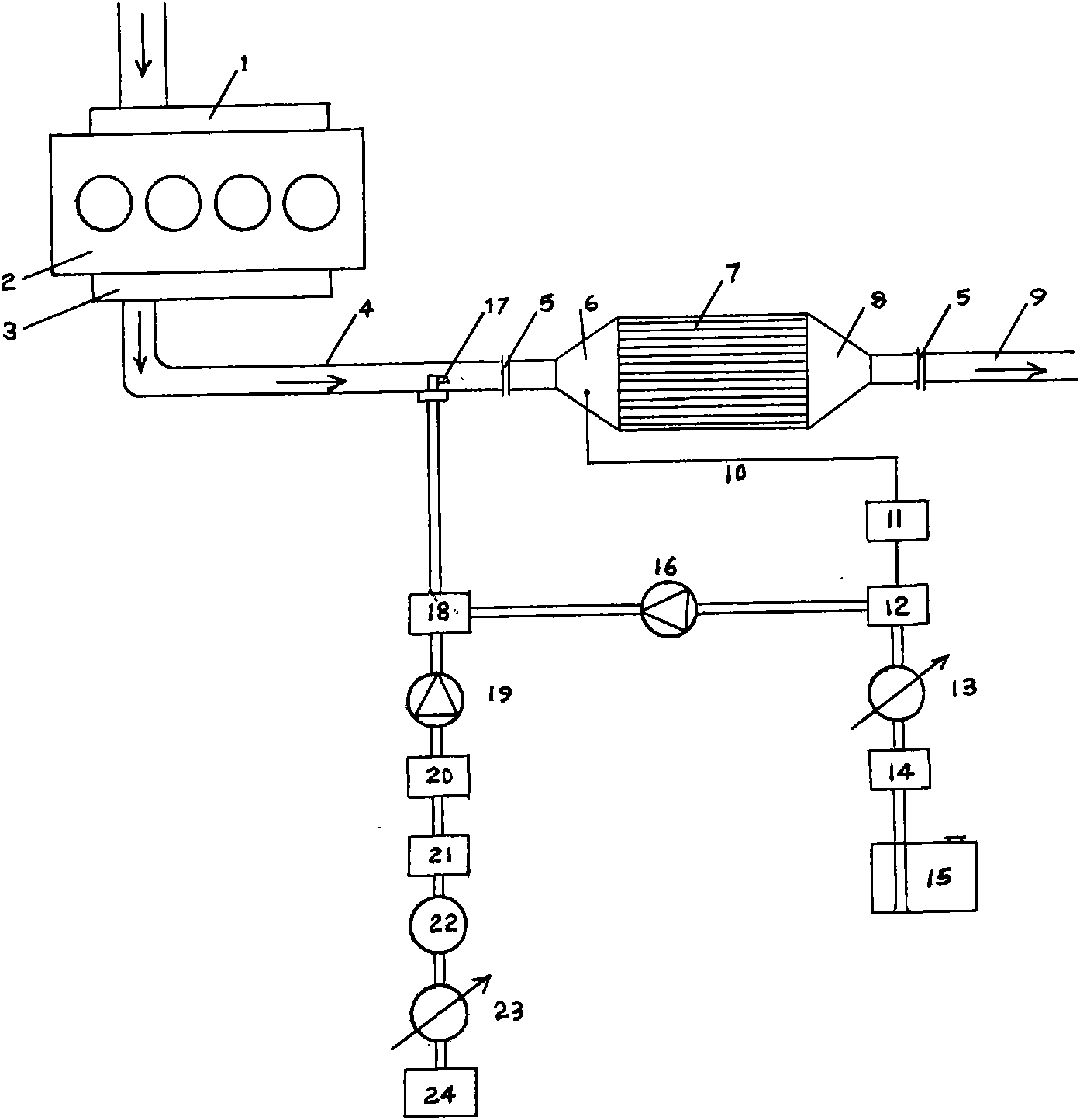

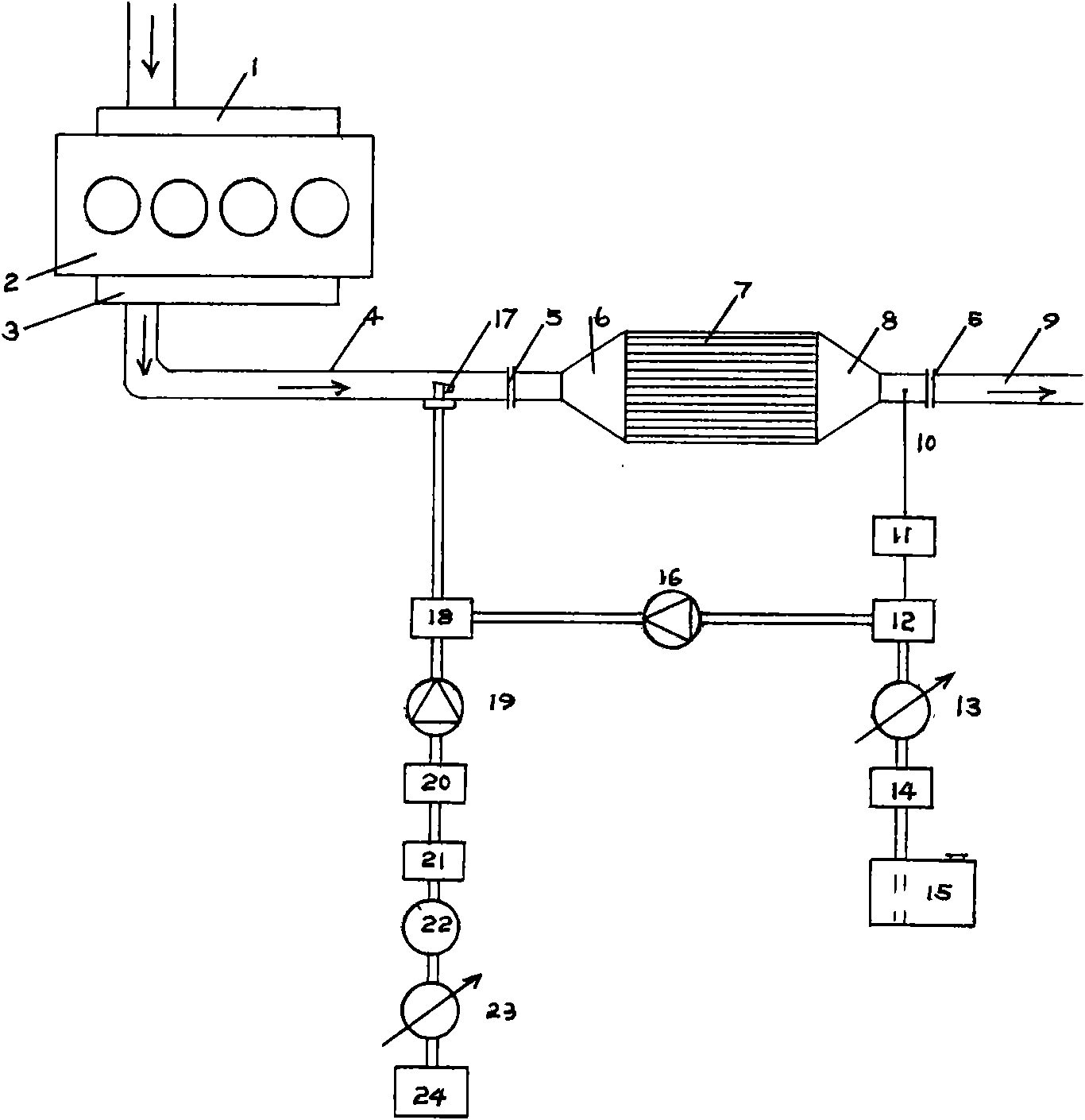

[0022] Attached below figure 1 The present invention is further described: as figure 1 As shown, a vehicle-mounted SCR metering injection system with exhaust temperature as a variable includes an engine intake manifold 1, an automobile engine 2, an engine exhaust manifold 3, an engine exhaust pipe 4, and an SCR post-processor coupling 5 , SCR post-processor inlet end expansion pipe 6, SCR post-processor 7, SCR post-processor outlet taper pipe 8, engine exhaust tail pipe 9; it is characterized in that: the urea reducing agent is transported by the pipeline system and compressed air The pipeline system is composed of two parts. In the urea reducing agent delivery pipeline system, the precision thermocouple 10 is connected with the temperature control unit 11 composed of an intelligent PID controller and a self-programmed computer program, and is installed on the expansion pipe 6 at the inlet end of the SCR post-processor, so as to The electromagnetic metering diaphragm pump 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com