Super-thick quenched and tempered steel plate with good obdurability matching, and manufacturing method thereof

A technology of quenched and tempered steel plate and manufacturing method, which is applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., and can solve the problems of uneven strength and toughness of extra thick quenched and tempered steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

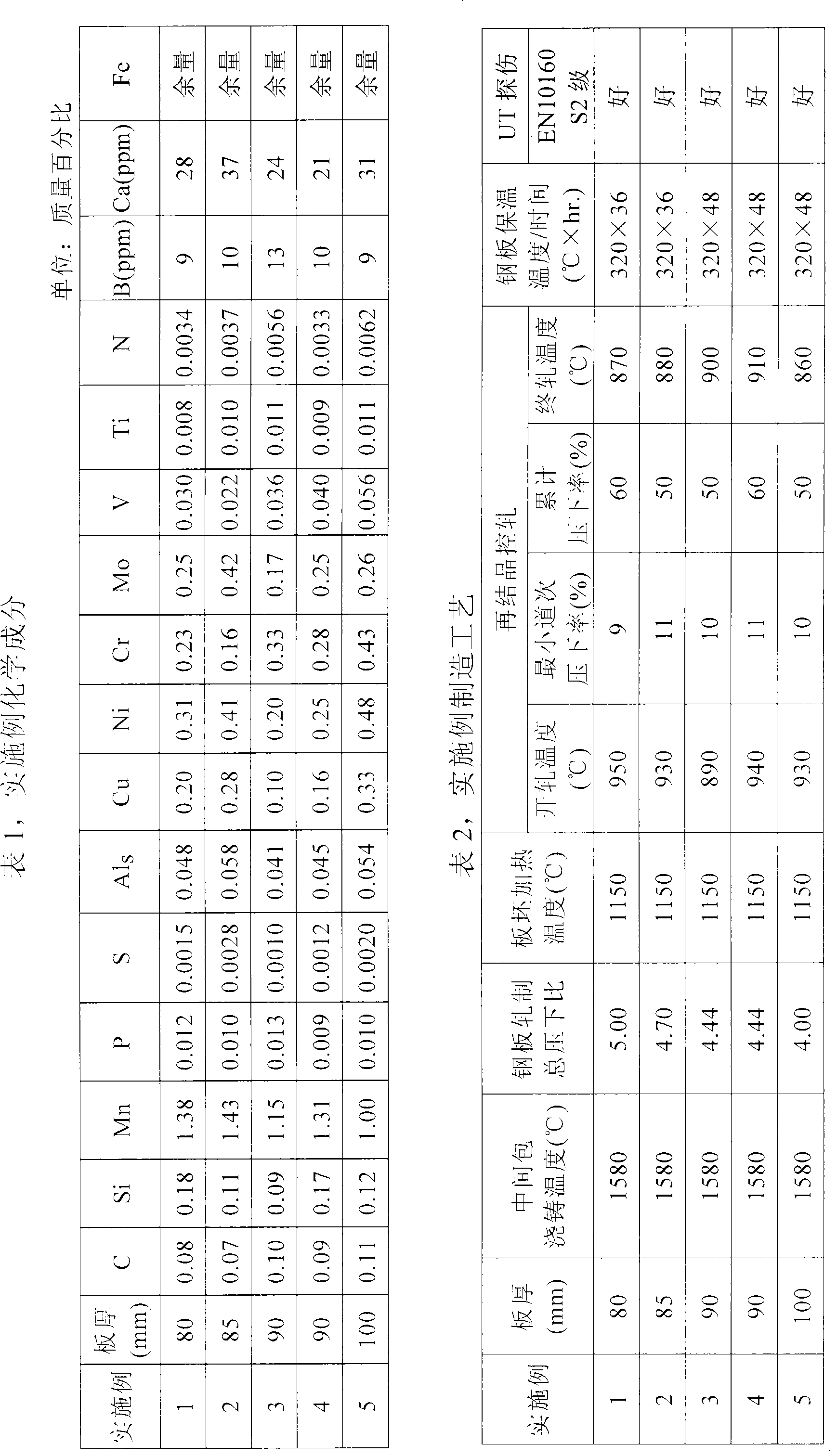

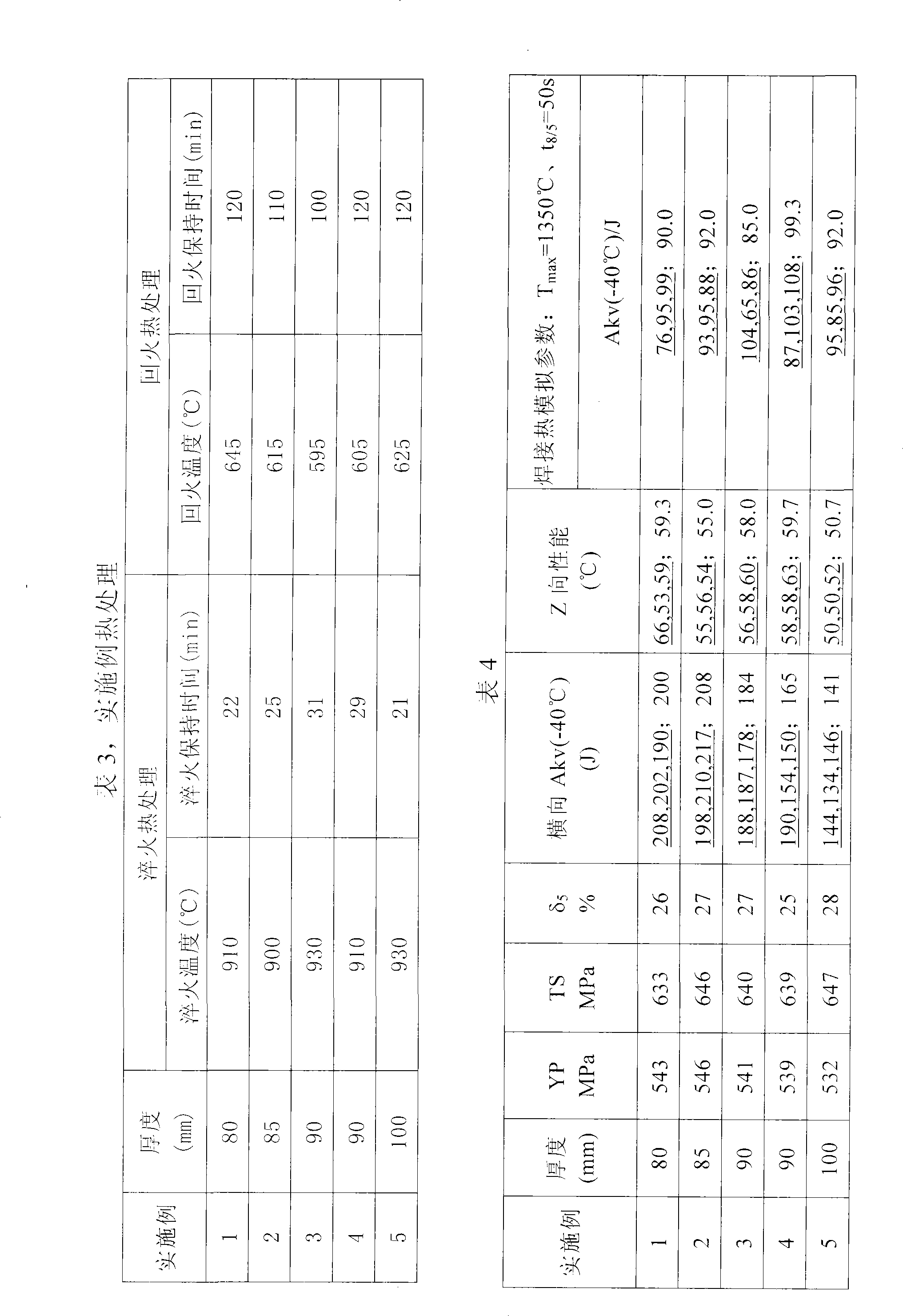

[0072] For the examples of the present invention, refer to Tables 1 to 3, and Table 4 shows the performance of the steel plate of the present invention.

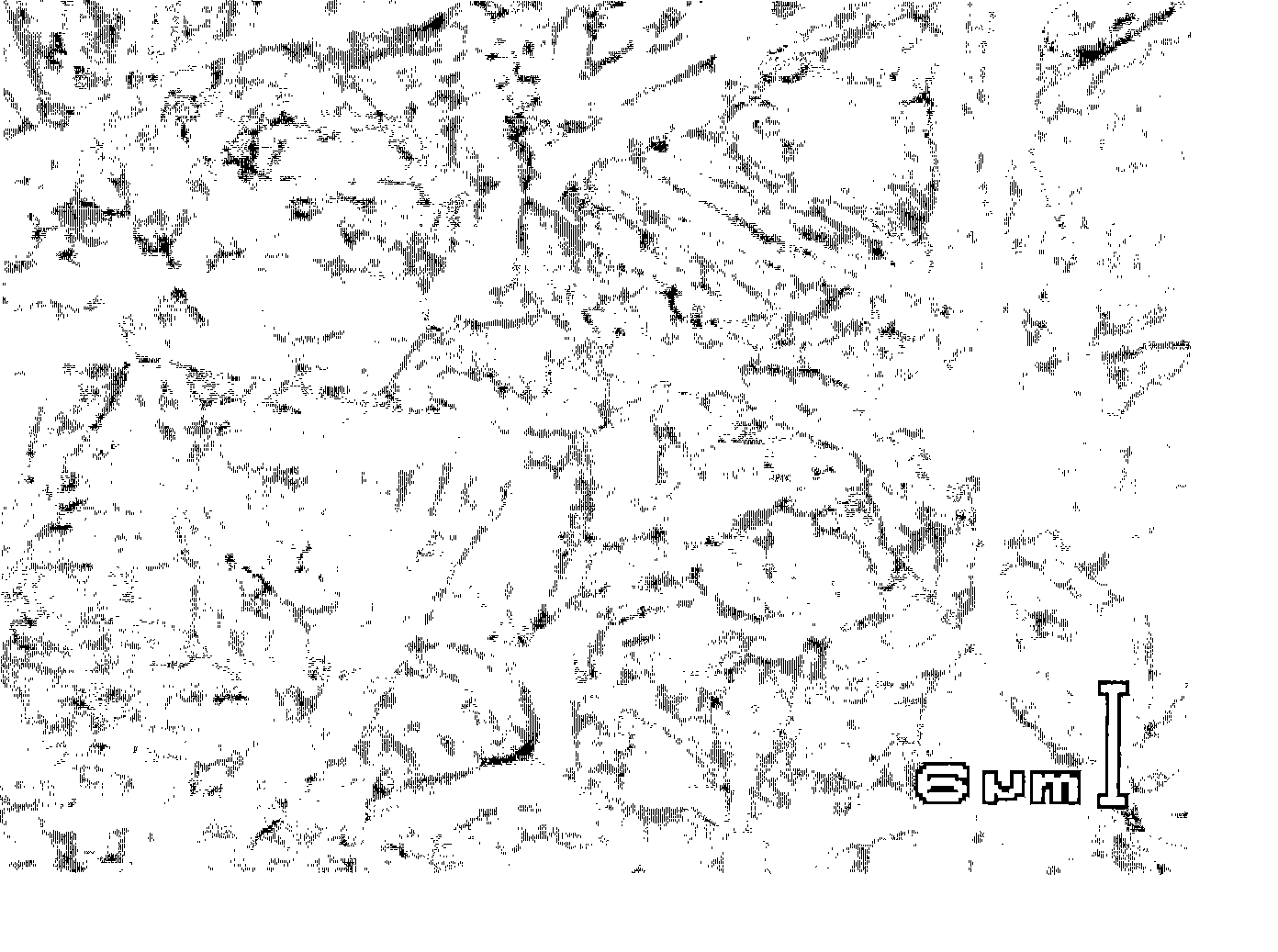

[0073] From figure 1 It can be seen that the microstructure of the steel plate of the present invention is fine tempered bainite, and the average grain size is below 25 μm.

[0074] It can be seen from Table 4 that the minimum elongation δ5 of the steel plate of the present invention reaches 25% (for quenched and tempered steel, this value is already a very high elongation, generally below 20%), and the single lowest impact energy at -40°C The value is 134J (for extra-thick steel plates, this value is already very high, generally below 100J); the single minimum value of impact energy in the welding heat-affected zone (HAZ) at -40°C is 65J, which shows that the steel plate tool of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com