Low-smoke halogen free flame retardant, preparation method and method thereof for preparing flame-resistant materials

A technology of flame retardants and flame retardants, applied in the direction of fireproof coatings, etc., can solve the problems of human injury, less usage, flammability, etc., achieve good flame retardant effect, reduce hydrogen bromide and smoke, and simple manufacturing method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

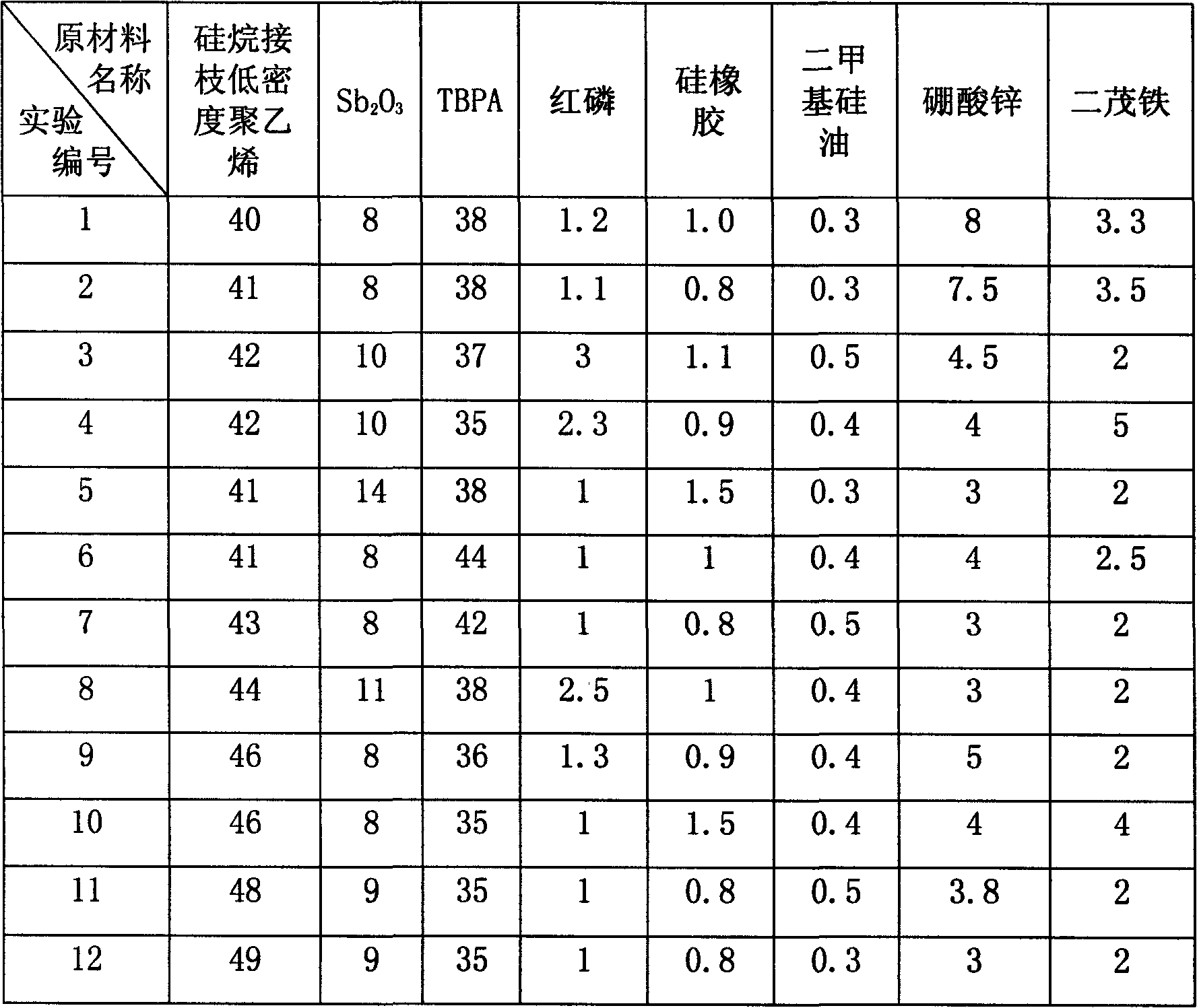

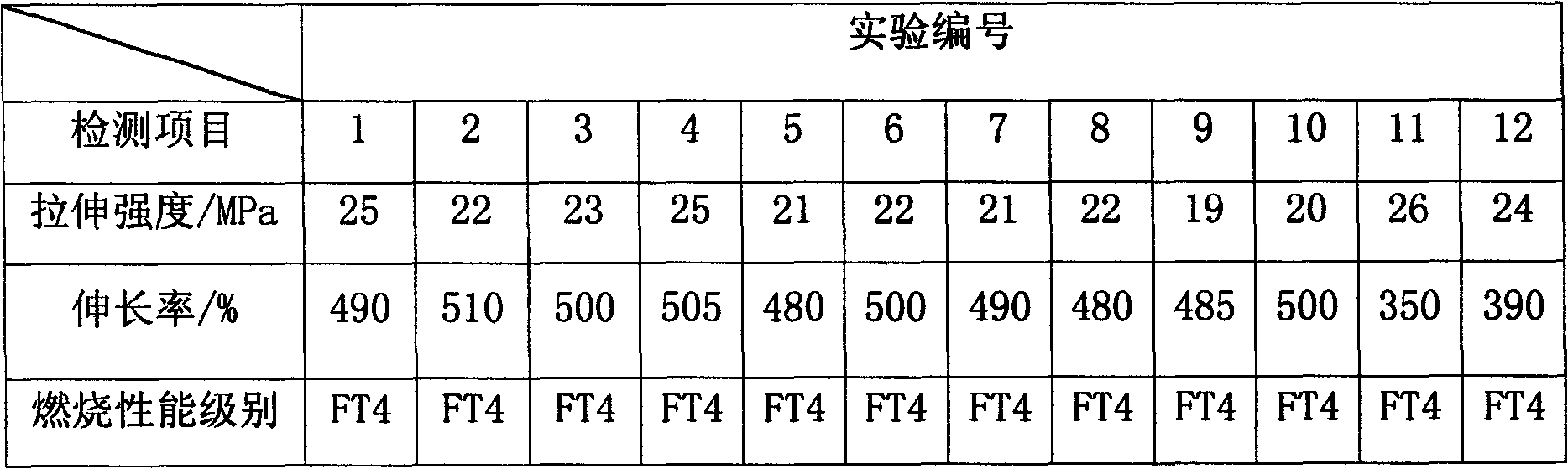

[0015] As a preferred version of the present invention, the flame retardant not only contains 40-50 parts of silane-grafted low-density polyethylene, 8-15 parts of antimony trioxide, 35-45 parts of tetrabromophthalic anhydride And 2-5 parts of ferrocene, and also includes 1-3 parts of red phosphorus and 0.8-1.5 parts of silicon rubber.

[0016] The red phosphorus and silicone rubber can reduce the amount of flame retardant, improve flame retardant efficiency and low cost, red phosphorus and silicone rubber can also endow the flame retardant material with better physical and mechanical properties, that is, it can prevent burning The resulting dripping phenomenon.

[0017] As another preferred solution of the present invention, the flame retardant further includes 0.3-0.5 parts of simethicone oil.

[0018] Simethicone oil is odorless and non-toxic, with physiological inertness, good chemical stability, electrical insulation and weather resistance, wide range of viscosity, low f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com