Water atomizing steel powder used for high-compressibility sintering hardening and production method thereof

A technology of sinter hardening and high compressibility, which is applied in the field of alloy powder manufacturing for high-performance powder metallurgy. It can solve the problems of loss of strengthening effect and sinter hardening effect of oxides, influence of powder compressibility, and increased powder cost, etc., to achieve material cost reduction. , saving energy consumption and low product price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

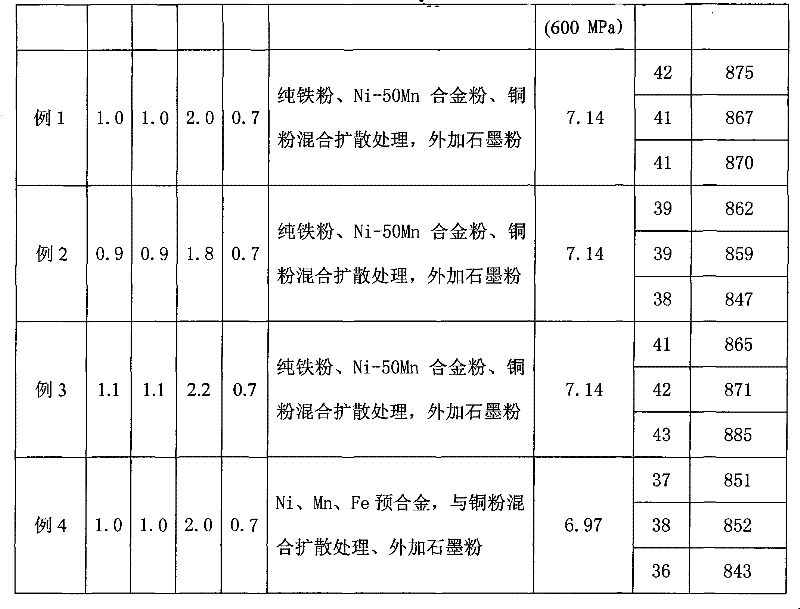

Embodiment 1

[0012] Choose 960kg compressibility as 7.12g / cm 3 (under the condition of 600MPa), add 20kgNi-50Mn gas-atomized alloy powder and 20kg-300mesh electrolytic copper powder to the water-atomized pure iron powder, place it in a 1000L batch machine and mix for 1 hour, take it out and input it into the steel belt reduction Diffusion is carried out in the annealing furnace, and the diffusion temperature is set at 820°C. After diffusion, the -100 mesh sintered hardened alloy powder is obtained by crushing, sieving and classification, and the measured powder compressibility is 7.14g / cm 3 (under the condition of 600MPa); select 25kg of the powder, add 0.175kg-500 mesh graphite powder and 0.175kg zinc stearate powder (lubricant), mix in V-type mixer for 1 hour, and press (600MPa) to form The standard sample was sintered in a sintering furnace at a temperature of 1120°C for 1 hour, and several test pieces were obtained. The test results are as follows:

[0013] Numbering

Embodiment 2

[0015] Select 964kg with a compressibility of 7.12g / cm 3 (under the condition of 600MPa), add 18kgNi-50Mn alloy powder and 18kg-300mesh electrolytic copper powder, put it in a 1000L batch machine and mix for 1 hour, take it out and put it into the steel belt reduction annealing furnace Diffusion is carried out, and the diffusion temperature is set at 820°C. After diffusion, it is crushed, sieved and classified to obtain -100 mesh sintered hardened alloy powder. The measured powder compressibility is 7.14g / cm 3 (under the condition of 600MPa); select 25kg of the powder, add 0.175kg-500 mesh graphite powder and 0.175kg zinc stearate powder (lubricant), mix in V-type mixer for 1 hour, and press (600MPa) to form The standard sample was sintered in a sintering furnace at a temperature of 1120°C for 1 hour, and several test pieces were obtained. The test results are as follows:

[0016] Numbering

Embodiment 3

[0018] Select 956kg with a compressibility of 7.12g / cm 3 (under the condition of 600MPa), add 22kgNi-50Mn alloy powder and 22kg-300mesh electrolytic copper powder, put it in a 1000L batch machine and mix for 1 hour, take it out and put it into the steel belt reduction annealing furnace Diffusion is carried out, and the diffusion temperature is set at 820°C. After diffusion, it is crushed, sieved and classified to obtain -100 mesh sintered hardened alloy powder. The measured powder compressibility is 7.14g / cm 3 (under the condition of 600MPa); select 25kg of the powder, add 0.175kg-500 mesh graphite powder and 0.175kg zinc stearate powder (lubricant), mix in V-type mixer for 1 hour, and press (600MPa) to form The standard sample was sintered in a sintering furnace at a temperature of 1120°C for 1 hour, and several test pieces were obtained. The test results are as follows:

[0019] Numbering

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com