Water atomizing steel powder used for high-compressibility sintering hardening and production method thereof

A sintering hardening, high compressibility technology, applied in the field of high-performance powder metallurgy alloy powder manufacturing, can solve the problems of powder compressibility, loss of oxide strengthening effect and sintering hardening effect, increase powder cost, etc., to reduce material cost , the effect of saving energy consumption and low product price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

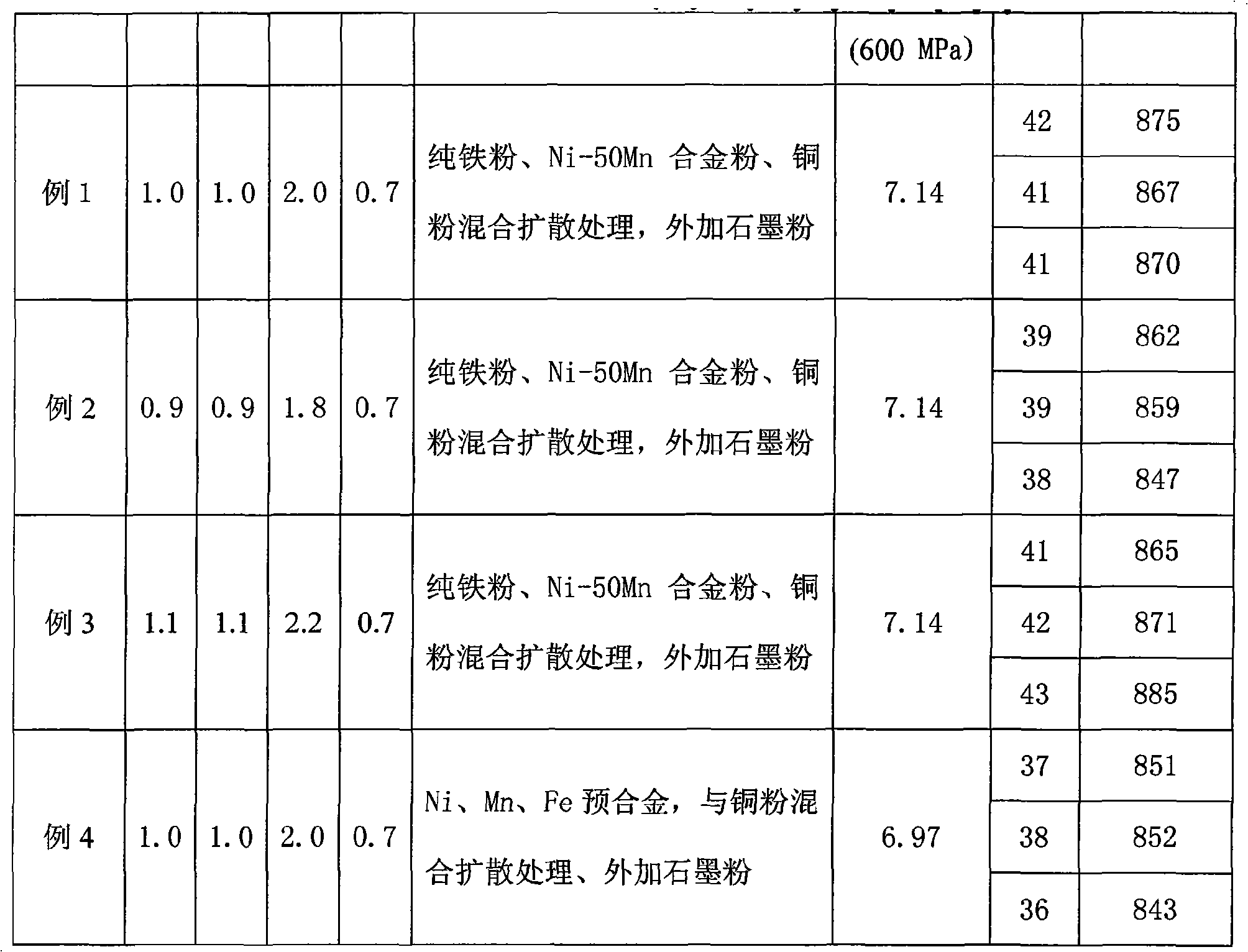

Embodiment 1

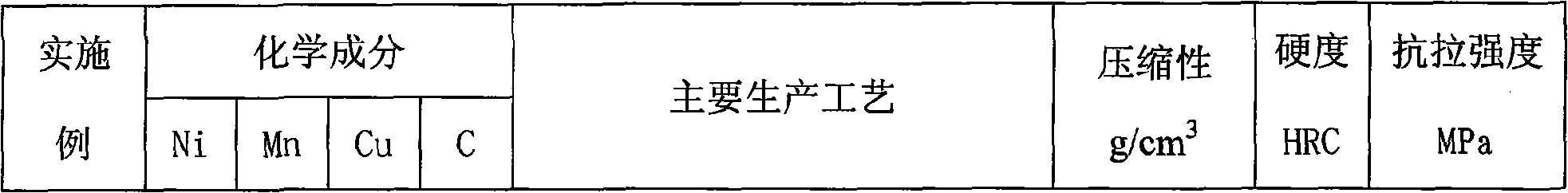

[0012] Choose 960kg compressibility as 7.12g / cm 3 (under the condition of 600MPa), add 20kgNi-50Mn gas-atomized alloy powder and 20kg-300mesh electrolytic copper powder to the water-atomized pure iron powder, place it in a 1000L batch machine and mix for 1 hour, take it out and input it into the steel belt reduction Diffusion is carried out in the annealing furnace, and the diffusion temperature is set at 820°C. After diffusion, the -100 mesh sintered hardened alloy powder is obtained by crushing, sieving and classification, and the measured powder compressibility is 7.14g / cm 3 (under the condition of 600MPa); select 25kg of the powder, add 0.175kg-500 mesh graphite powder and 0.175kg zinc stearate powder (lubricant), mix in V-type mixer for 1 hour, and press (600MPa) to form The standard sample was sintered in a sintering furnace at a temperature of 1120°C for 1 hour, and several test pieces were obtained. The test results are as follows:

[0013] Numbering

Embodiment 2

[0015] Select 964kg with a compressibility of 7.12g / cm 3 (under the condition of 600MPa), add 18kgNi-50Mn alloy powder and 18kg-300mesh electrolytic copper powder, put it in a 1000L batch machine and mix for 1 hour, take it out and put it into the steel belt reduction annealing furnace Diffusion is carried out, and the diffusion temperature is set at 820°C. After diffusion, it is crushed, sieved and classified to obtain -100 mesh sintered hardened alloy powder. The measured powder compressibility is 7.14g / cm 3 (under the condition of 600MPa); select 25kg of the powder, add 0.175kg-500 mesh graphite powder and 0.175kg zinc stearate powder (lubricant), mix in V-type mixer for 1 hour, and press (600MPa) to form The standard sample was sintered in a sintering furnace at a temperature of 1120°C for 1 hour, and several test pieces were obtained. The test results are as follows:

[0016] Numbering

Embodiment 3

[0018] Select 956kg with a compressibility of 7.12g / cm 3 (under the condition of 600MPa), add 22kgNi-50Mn alloy powder and 22kg-300mesh electrolytic copper powder, put it in a 1000L batch machine and mix for 1 hour, take it out and put it into the steel belt reduction annealing furnace Diffusion is carried out, and the diffusion temperature is set at 820°C. After diffusion, it is crushed, sieved and classified to obtain -100 mesh sintered hardened alloy powder. The measured powder compressibility is 7.14g / cm 3 (under the condition of 600MPa); select 25kg of the powder, add 0.175kg-500 mesh graphite powder and 0.175kg zinc stearate powder (lubricant), mix in V-type mixer for 1 hour, and press (600MPa) to form The standard sample was sintered in a sintering furnace at a temperature of 1120°C for 1 hour, and several test pieces were obtained. The test results are as follows:

[0019] Numbering

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com