Hollow fiber ultrafiltration membrane filter device

A filtration device and ultrafiltration membrane technology, applied in ultrafiltration, membrane, membrane technology and other directions, can solve the problems of low elongation, difficult installation, fragile and other problems, achieve high impact strength, convenient production and assembly, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

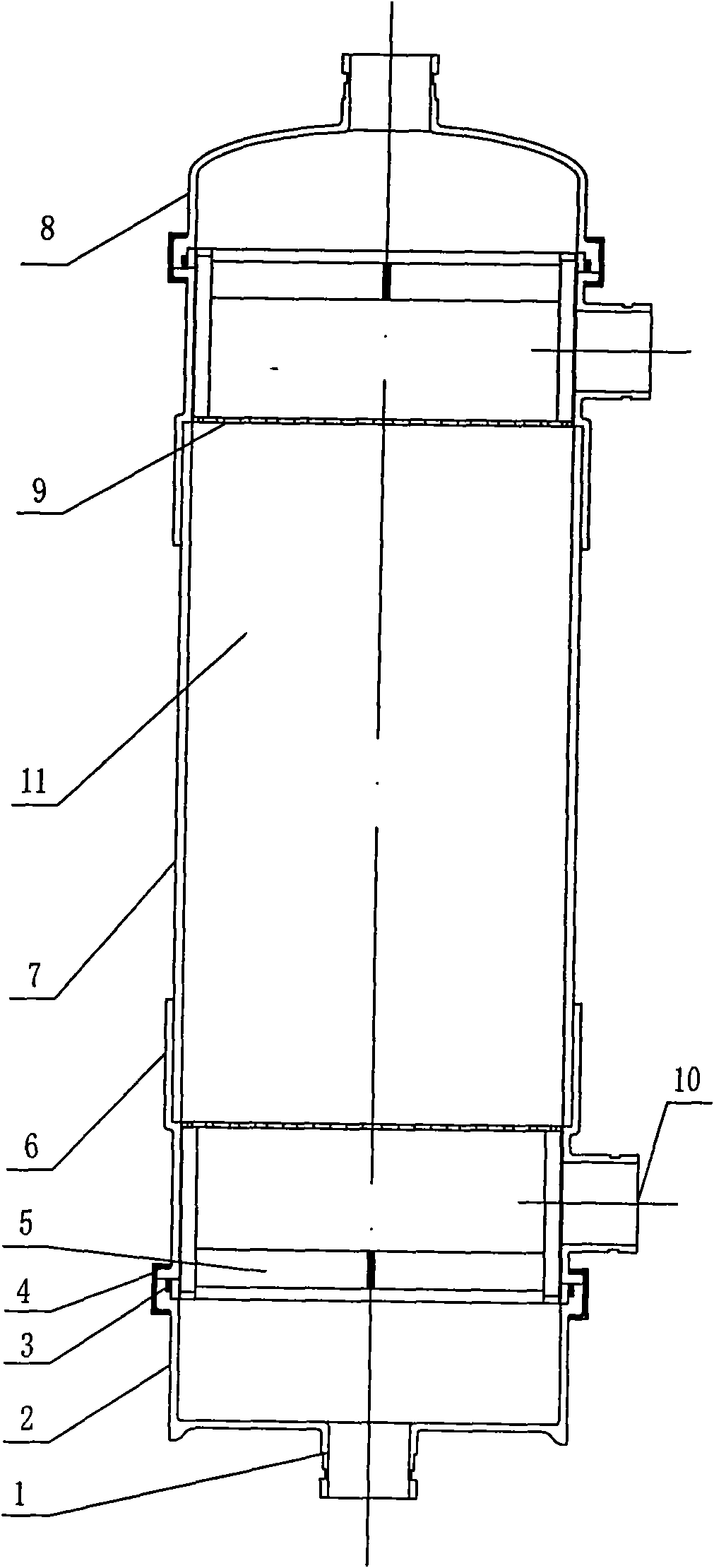

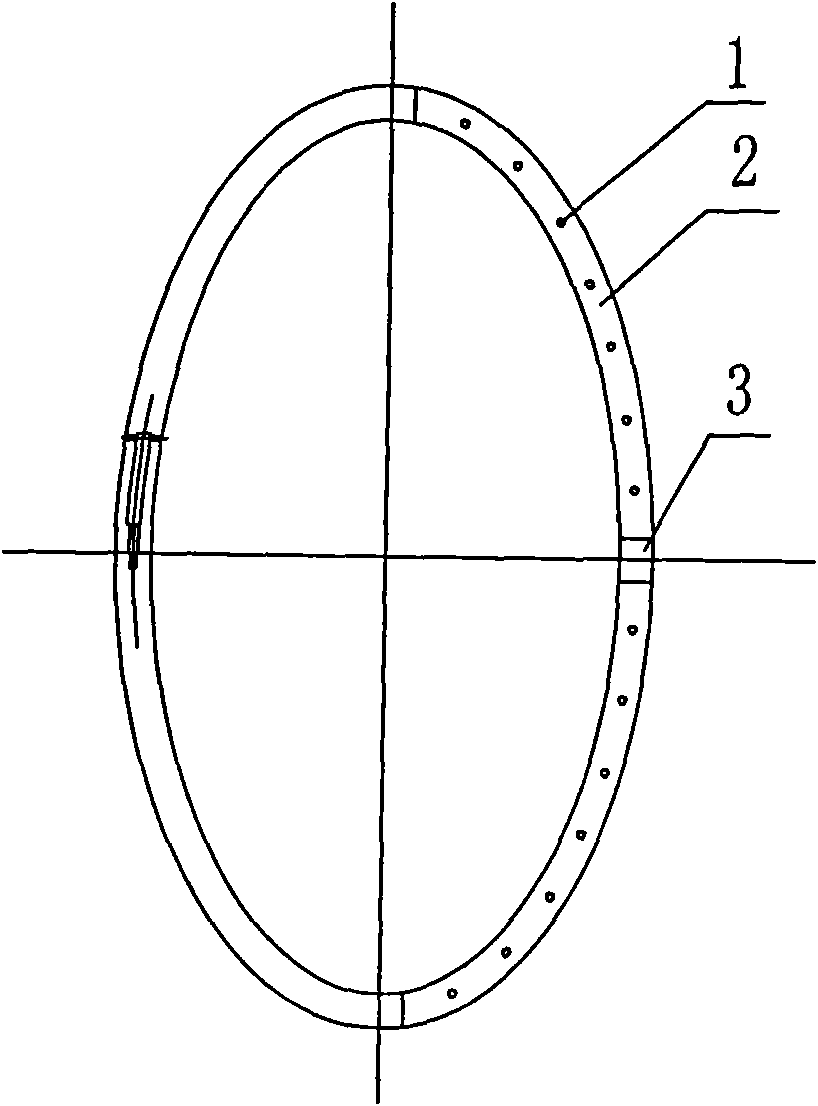

[0016] Such as figure 1 As shown, the upper and lower ends of the membrane main body 7 of the present invention are covered with an outer cylinder 6, and the interior of the membrane main body 7 is provided with a hollow fiber 11. The upper end of the hollow fiber 11 is provided with a water distributor 9, and the lower end is provided with a membrane lattice support. piece 5. Such as figure 2 As shown, the aperture of the water distribution hole of the water distributor 9 of the present invention gradually becomes larger as the distance from the water inlet 10 increases, and they are arranged in a ring shape. The size of the openings is based on the principle that the section of the water distribution hole is proportional to the water inlet flow path. The holes near the water inlet are small and few, and the holes far away from the water inlet are many and large. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com