Continuous vacuum crystallization device and application thereof

A technology of vacuum crystallization and crystallization kettle, applied in solution crystallization and other directions, can solve the problems of incompatibility with large-scale industrial needs, inability to continuously produce, energy loss, etc., and achieve the requirements of large-scale industrial production, stable liquid flow and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

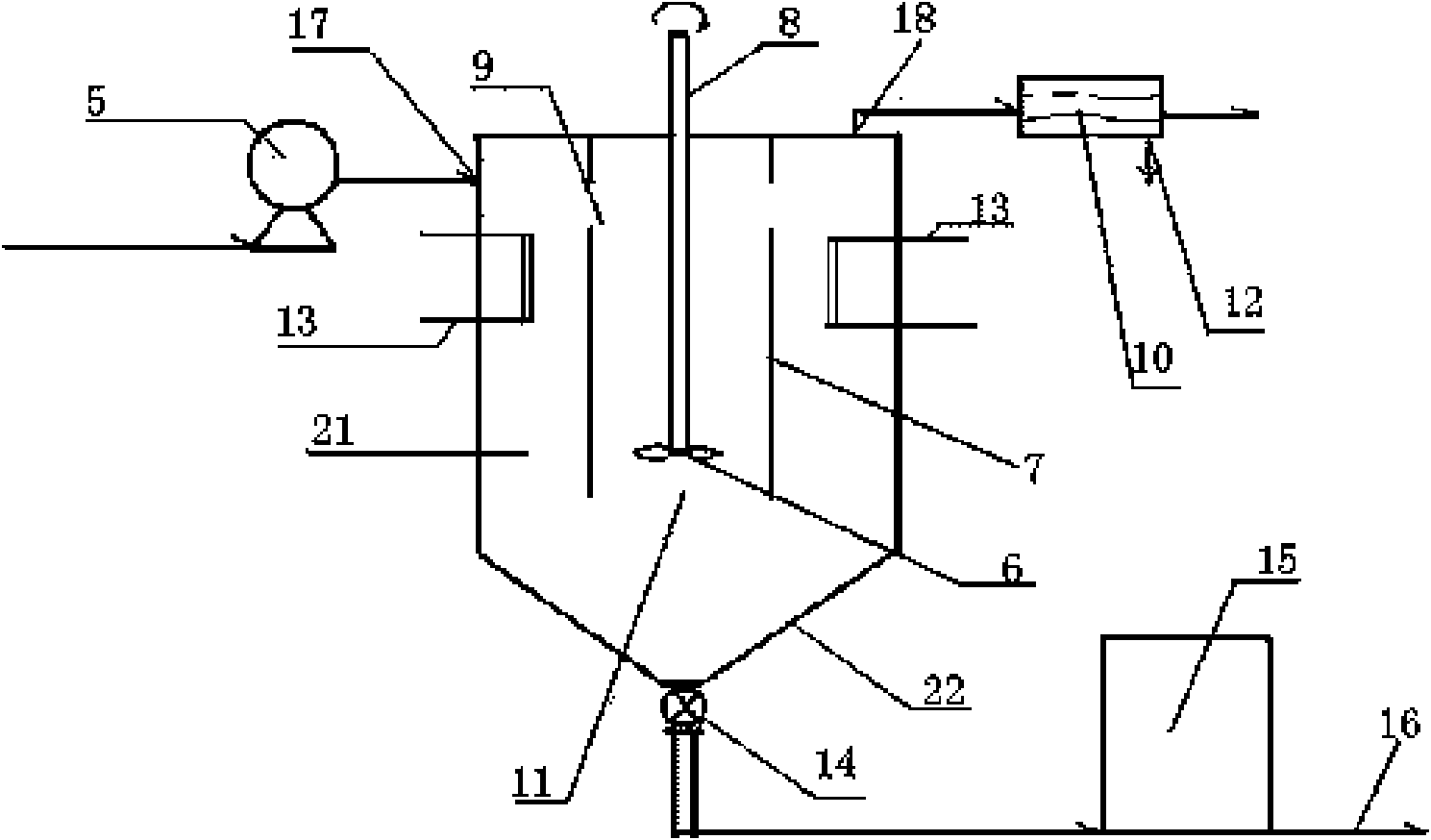

[0017] Example 1: Combining figure 1 The continuous vacuum crystallization device includes a crystallization kettle 21, a raw material pump 5 connected to the inlet 17 of the crystallization kettle through a pipeline, a vacuum condensation recoverer 10 connected to the water vapor outlet 18 of the crystallization kettle through a pipeline, an electric heating temperature control device 13, and an axial flow pump 6 , 7, 8, bottom valve 14, etc., the bottom 22 of the crystallization tank is in the shape of a cone, and the top of the cone is connected to the bottom valve 14 of the crystallization tank; the electric heating temperature control device 13 is installed at more than half of the height in the crystallization tank , Axial flow pumps 6, 7, 8 are vertically installed in the middle of the crystallization kettle. The distance between the pump impeller 6 and the top of the vertebral body at the bottom of the crystallization kettle should be greater than one-third of the inner...

Embodiment 2

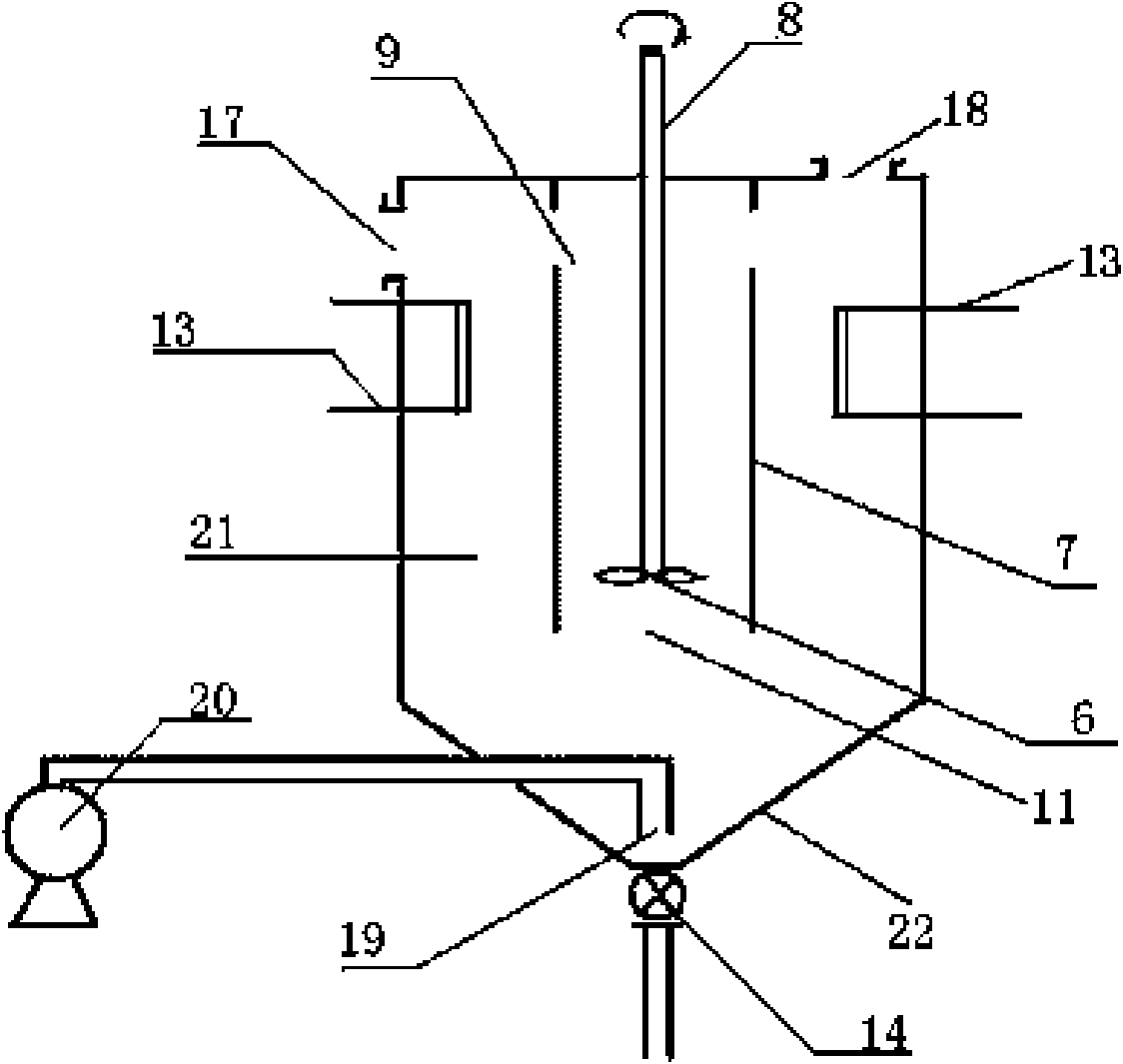

[0022] Example 2: Combining figure 2 Repeat embodiment 1 according to the same steps, but the bottom of the crystallization tank is provided with flow aids 19, 20, the flow aids include a fluid pump 20 and one end is connected with the fluid pump 20 and the other end outlet 19 is facing the valve 14 at the bottom of the crystallization tank The pipeline, the distance between pipeline outlet 19 and crystallization tank bottom valve is 100~500mm. The fluid pump 20 is a raw material liquid pump, which promotes the discharge of the product by pumping out the supersaturated solution of the corresponding crystal. During the production process, the crystals in the supersaturated solution settle at the bottom 22 of the crystallization kettle cone due to gravity, and when the discharge is not smooth, the flow-aid devices 19 and 20 are turned on to help discharge.

Embodiment 3

[0023] Embodiment 3: prepare barium chloride raw material liquid, the hydrated barium chloride raw material liquid that removes impurity through oxidation and filters is input crystallization kettle 21 through raw material pump 5, and electric heating temperature control device 13 heats and controls temperature to keep the temperature in crystallization kettle 21 At 100°C-113°C, preferably 103°C, the vacuum condensate recovery device 10 sucks water vapor and condenses it for recycling, the vacuum is maintained at 10-30Kpa, and the raw material liquid is formed in the crystallization tank 21 driven by the axial flow pumps 6, 7, and 8 The center of the kettle flows upwards, reaches the top of the kettle and then circulates downward along the wall of the kettle. The concentration of the raw material solution gradually increases. During the continuous process, the solute is thermally crystallized from the crystal nucleus to the crystal bell (induced by the first addition of the crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com