Power plant system and method for the operation thereof

A power station and equipment technology, applied in the field of power stations, can solve the problems of inverter power loss and inability to improve efficiency, and achieve the effect of high-efficiency emission value and low emission value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

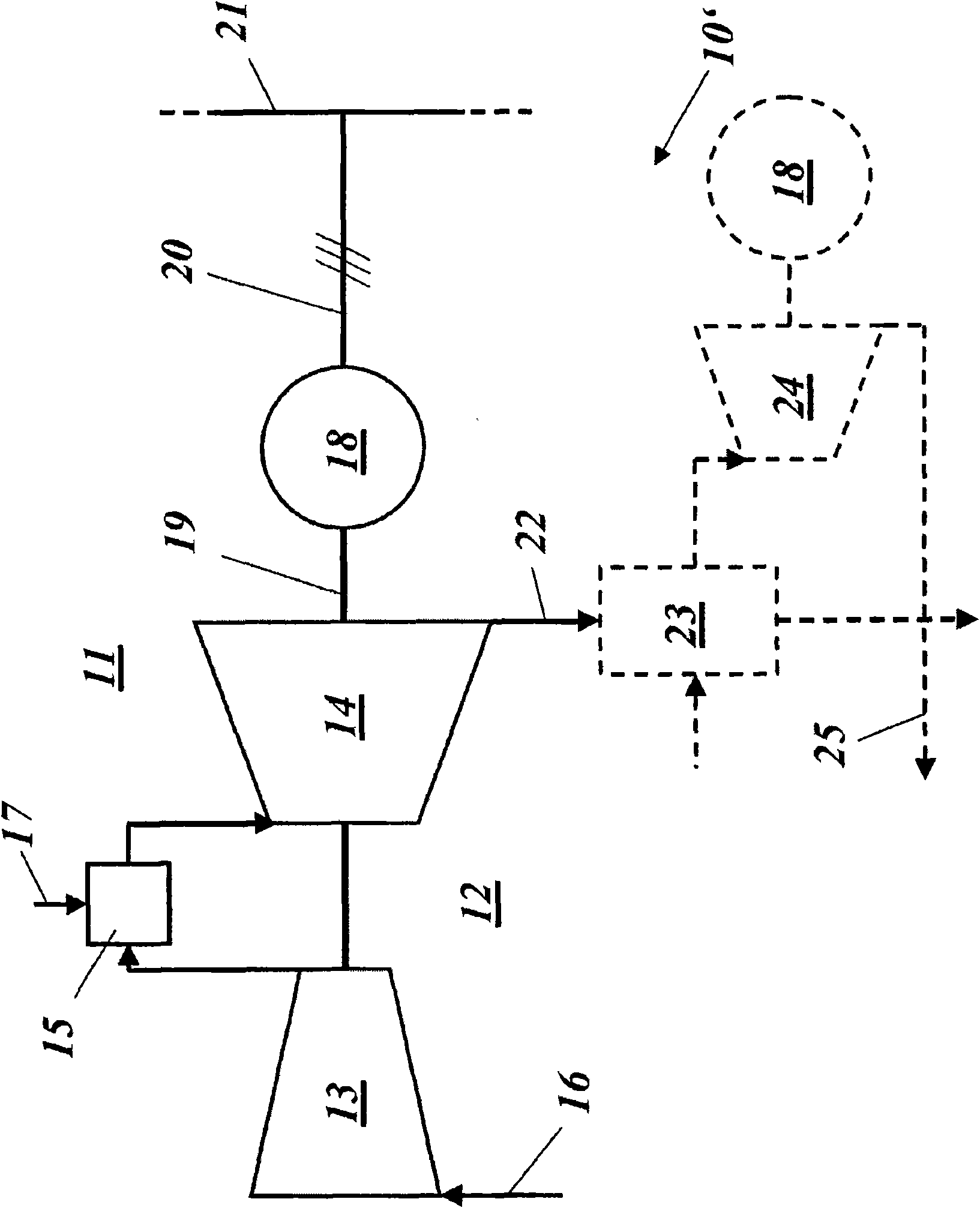

[0050] According to one embodiment of the present invention, in Figure 4 shows a power station installation with gas turbine and electronic decoupling in a very simplified circuit diagram. The power plant installation 10 comprises a gas turbine 12 with a compressor 13 and a continuous combustion plant, wherein a first combustion chamber 15 generates hot gas from a first fuel via a first fuel supply 17, which is expanded in a first turbine 14a It is then introduced into the second combustion chamber 15', where the passage of the second fuel through the second fuel supply 17' brings about a second increase in the temperature of the hot gas, which is then expanded in the second turbine 14b. Instead of a continuous combustion system, which is particularly effective in terms of efficiency, it is also possible to provide a single-stage combustion system. The rest of the equipment corresponds to the figure 2 or image 3 Components with the same reference numerals.

[0051] The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com